Pymetrozine powder drying machine

A technology of pymetrozine powder and drying machine, which is applied in the direction of drying machine, drying solid material, drying gas arrangement, etc. It can solve the problems of ineffective drying, unstable steam heating, high water content of products, etc., and achieve low loss , reduce manual labor, fully and evenly dry the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

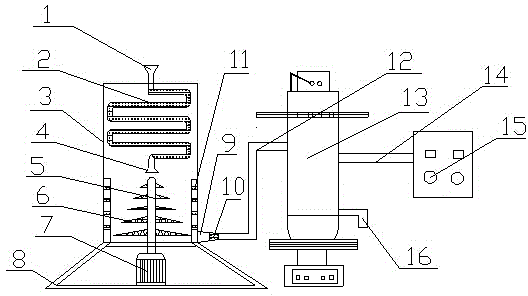

[0012] Such as figure 1 As shown, a pymetrozine powder dryer includes a dryer body 3, a hopper 1, a discharge port 16 and a motor 7, the dryer body 3 is supported on a base 8, and the motor 7 is provided with The stirring shaft 5 passes through the inside of the dryer body 3, the feed hopper 1 is arranged on the top of the dryer body 3, and communicates with the dryer body 3, and one end of the feed hopper 1 is connected to the S-shaped Electric heater 2, the end of the electric heater 2 is provided with a nozzle 4, the lower end of the dryer body 3 is provided with a trumpet-shaped joint 9, and the other end of the joint 9 is connected to the vacuum feeding pipe 12 Machine 13 provides negative pressure through the vacuum feeder provided. Due to the negative pressure in the feeding pipe, the pymetrozine powder that meets the requirements enters the vacuum feeder, so as to realize the collection of powdery materials and avoid manual collection. Reduce manual labor.

[0013] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com