System and method for determining and mitigating turbine degradation in variable geometry turbocharger

一种涡轮、劣化的技术,应用在装料系统、机器/发动机、电气控制等方向,能够解决错误确定劣化、涡轮响应减慢、卡住等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

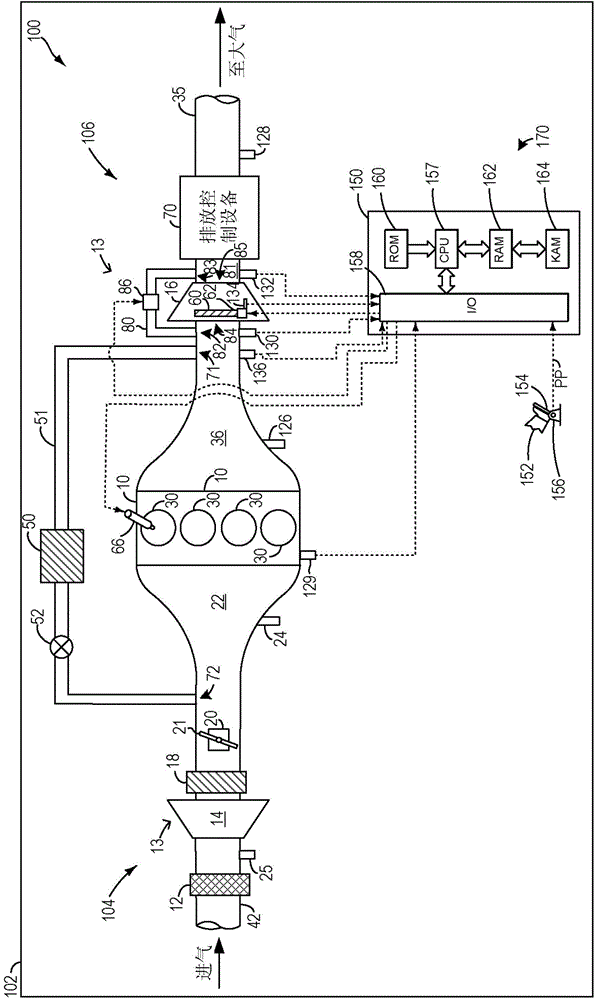

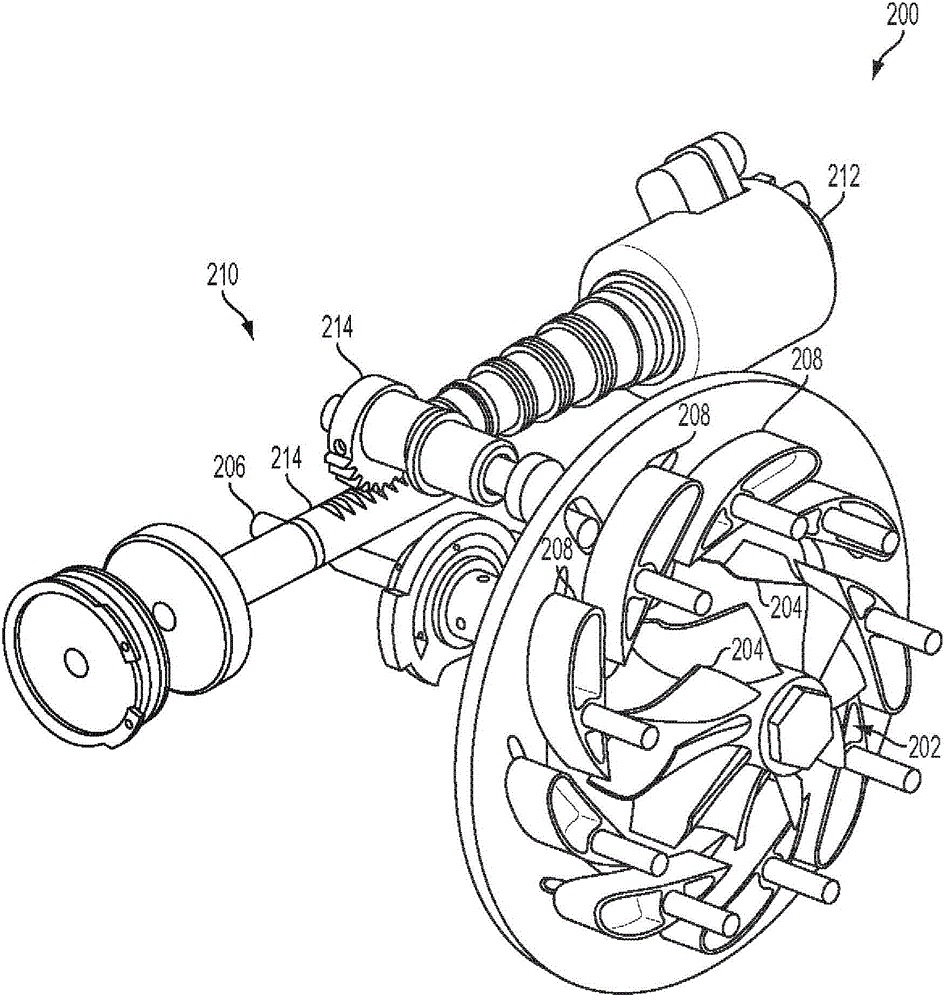

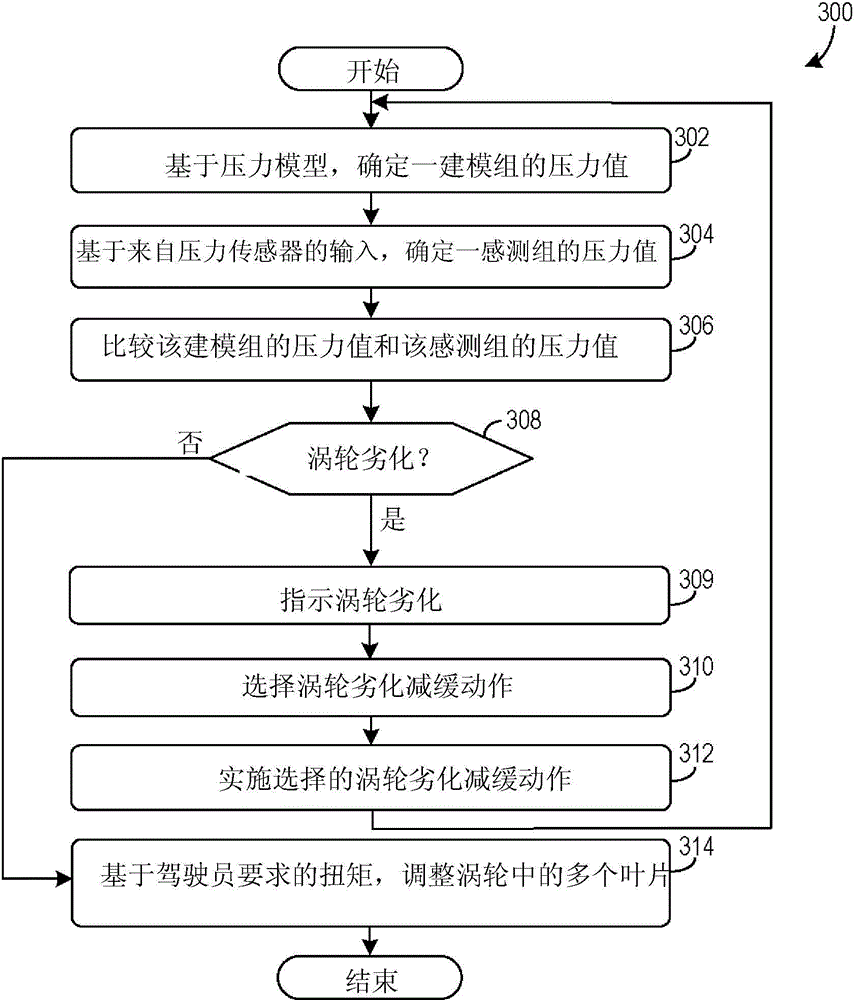

[0016] Systems and methods for determining and mitigating turbine degradation in variable geometry turbochargers are described herein. Specifically, the system and method may be used to accurately determine turbine degradation based on a comparison of modeled and sensed pressure values both upstream and downstream of the turbine. In this way, a comparison of the modeled pressure across the turbine and the sensed pressure across the turbine may be used to increase the accuracy of turbine degradation determinations. As a result, turbo degradation (eg, faults) may be diagnosed more quickly over a wider range of engine operating conditions, thereby improving turbo degradation diagnostic techniques in vehicle systems. Further, in some examples, the method may additionally include, in response to determining variable geometry turbine degradation, selecting from a set of turbine degradation mitigation actions based on a comparison of the modeled set of turbine pressure values and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com