High-integrality robot joint

A robot joint, highly integrated technology, applied in manipulators, manufacturing tools, joints, etc., can solve the problems of low integration, small load, large weight, etc., and achieve the effect of high integration, large load capacity, and low self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, the present invention will be further described in conjunction with the drawings and specific embodiments.

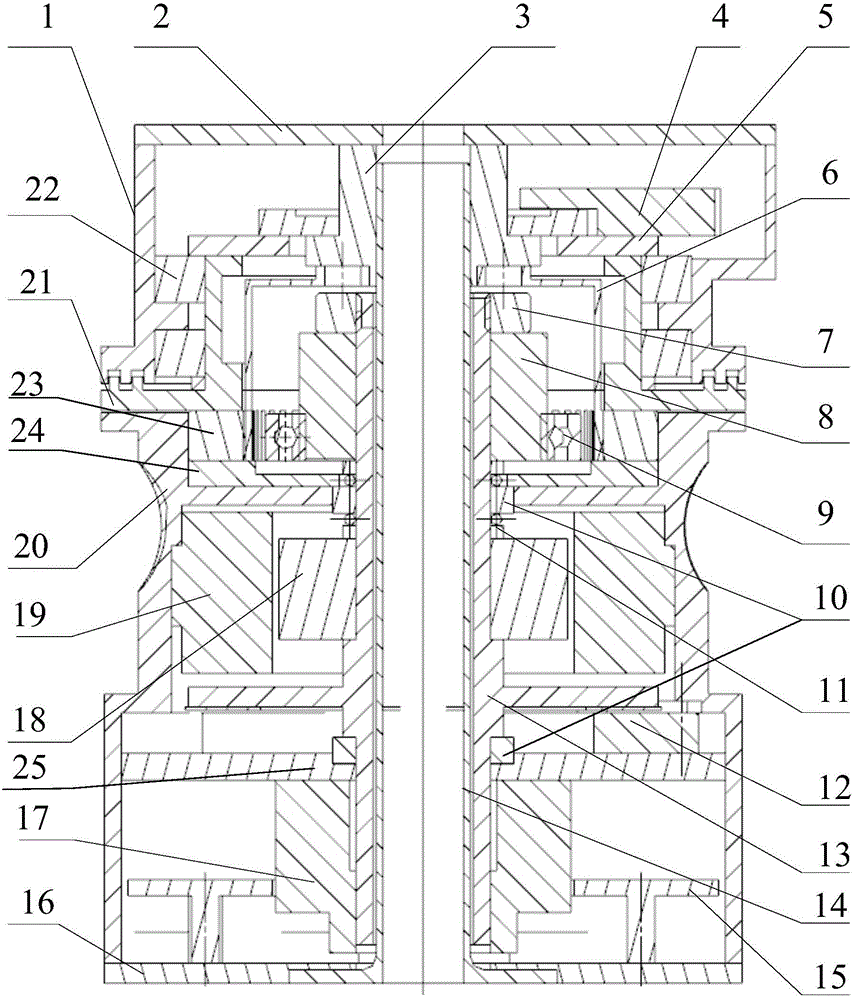

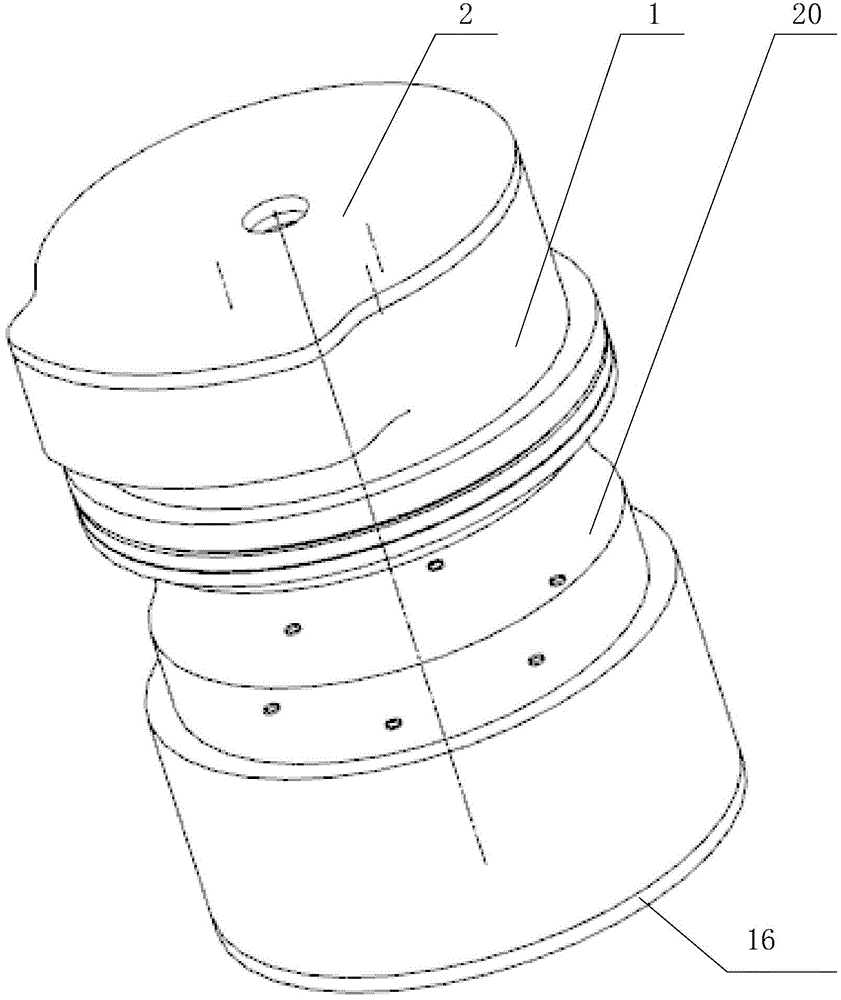

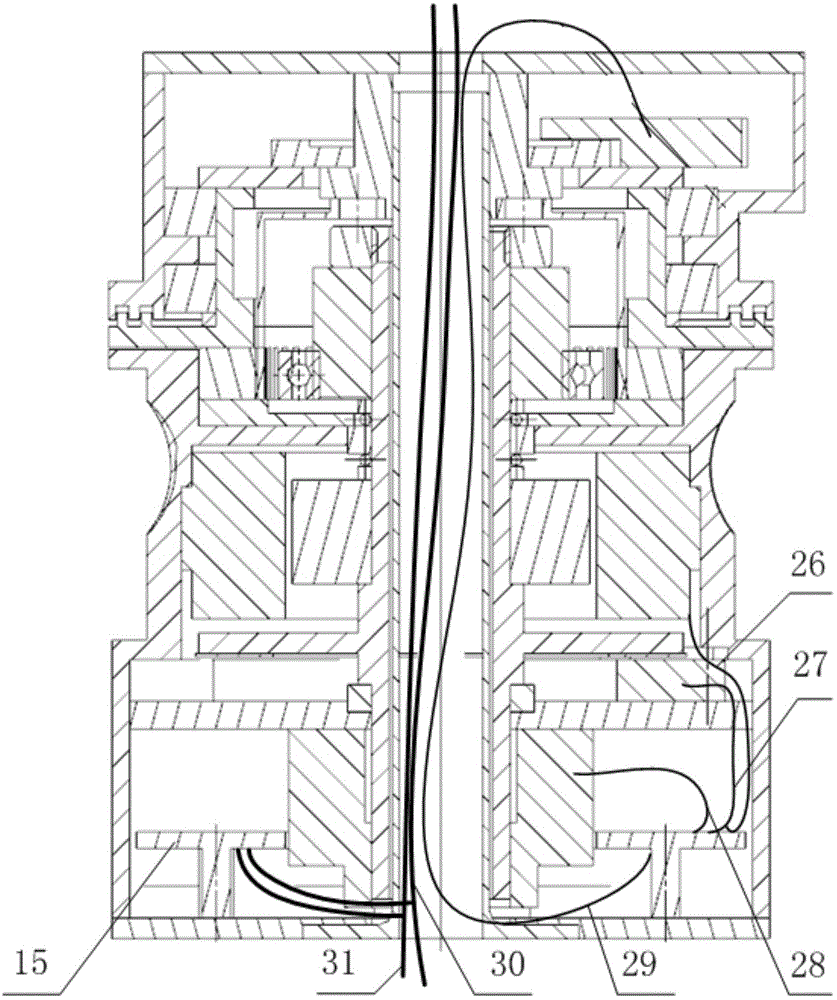

[0021] combine Figure 1-Figure 4 Note that the highly integrated joint in this embodiment mainly includes a mechanical system, a joint electrical system, and a sensor system; the mechanical system, the joint electrical system, and the sensor system are integrated inside a joint, and are connected to an external mechanical structure through a standardized mechanical interface. The standardized electrical interface realizes the electrical connection with the outside; thus communicates with the upper computer controller through the bus, thereby realizing the position and speed control of the corresponding joints.

[0022] Its mechanical system is mainly composed of a mechanical casing, a drive motor, a transmission device, and a brake device as a power-off brake; the mechanical casing has a general mechanical interface and an electrical interface, so a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com