Drilling technological equipment with annular water spray cooling function

A drilling tooling and annular water spraying technology, applied in positioning devices, manufacturing tools, metal processing equipment, etc., can solve the problems of low processing qualification rate, difficult drilling processing, poor cooling effect, etc., and improve drilling efficiency. Efficiency and pass rate, good effect, high support stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

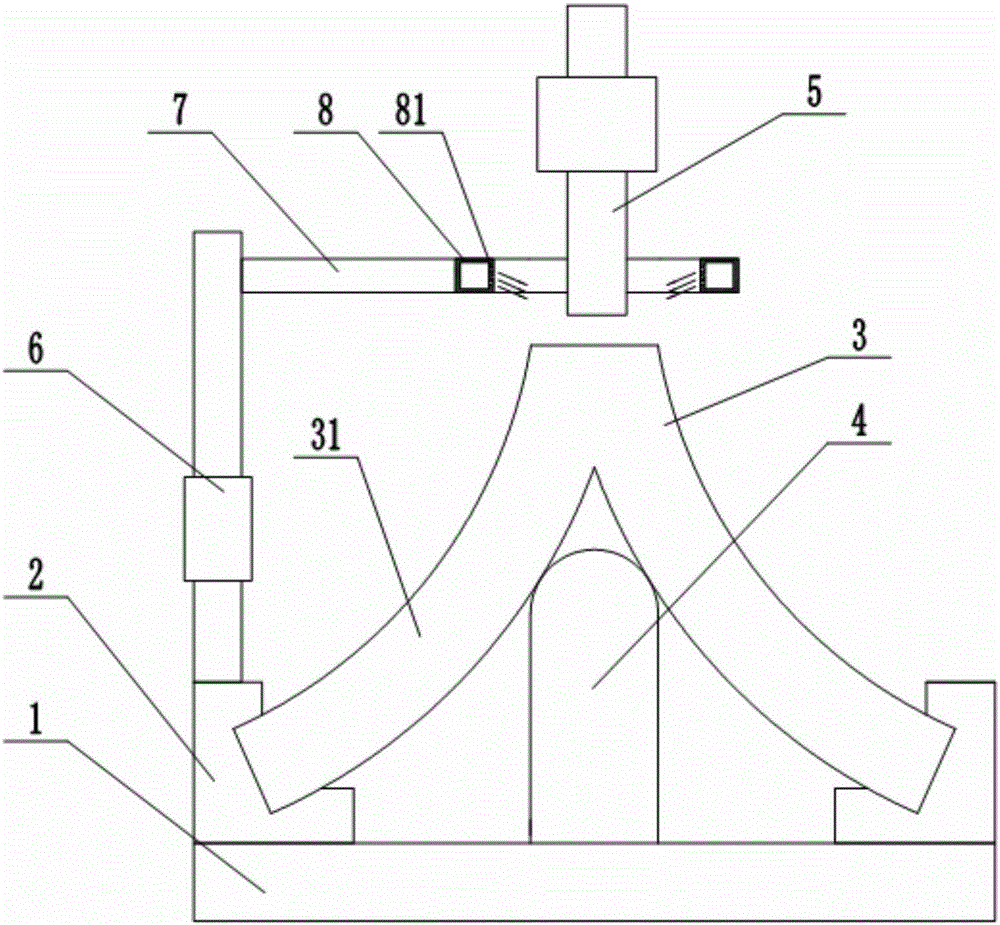

[0011] Such as figure 1 As shown, the drilling tool with annular water spray cooling in this embodiment includes a support base 1, and support bases 2 are symmetrically installed on both ends of the upper surface of the support base 1, and arc-shaped plates 31 at both ends of the V-shaped piece 3 are installed respectively. In the support seat 2, the upper surface of the support base 1 has a support column 4 in the middle, and the upper end of the support column 4 abuts against the bifurcation root of the V-shaped piece 3; a rotating lifting column 6 is installed on the support seat 2 on one side, The upper end of the rotating lifting column 6 is horizontally equipped with a support plate 7, and the end of the support plate 7 is equipped with a water spray ring 8, and the inner ring side wall of the water spray ring 8 has a spray hole 81 tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com