Crankshaft cleaning machine

A cleaning machine and crankshaft technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of deviation of the pressure head from the original working position, insufficient cleaning pressure, and small diameter of the crankshaft oil passage, etc. Achieve the effect of avoiding cleaning blind spots, avoiding ineffective cleaning, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

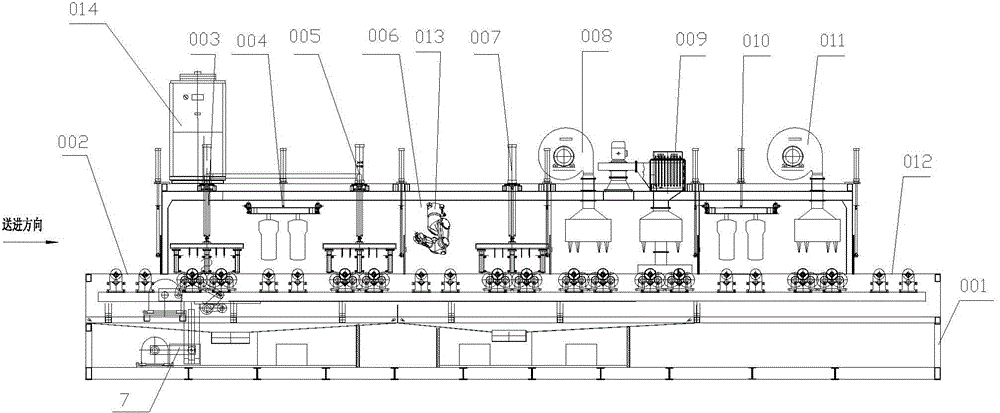

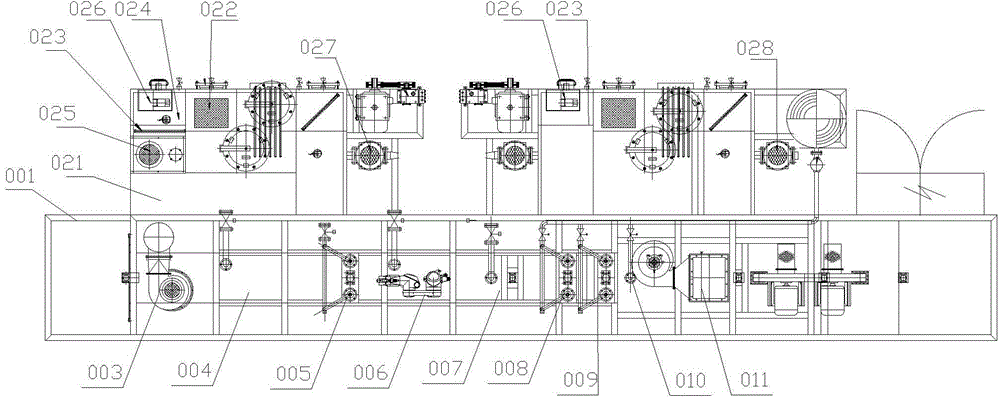

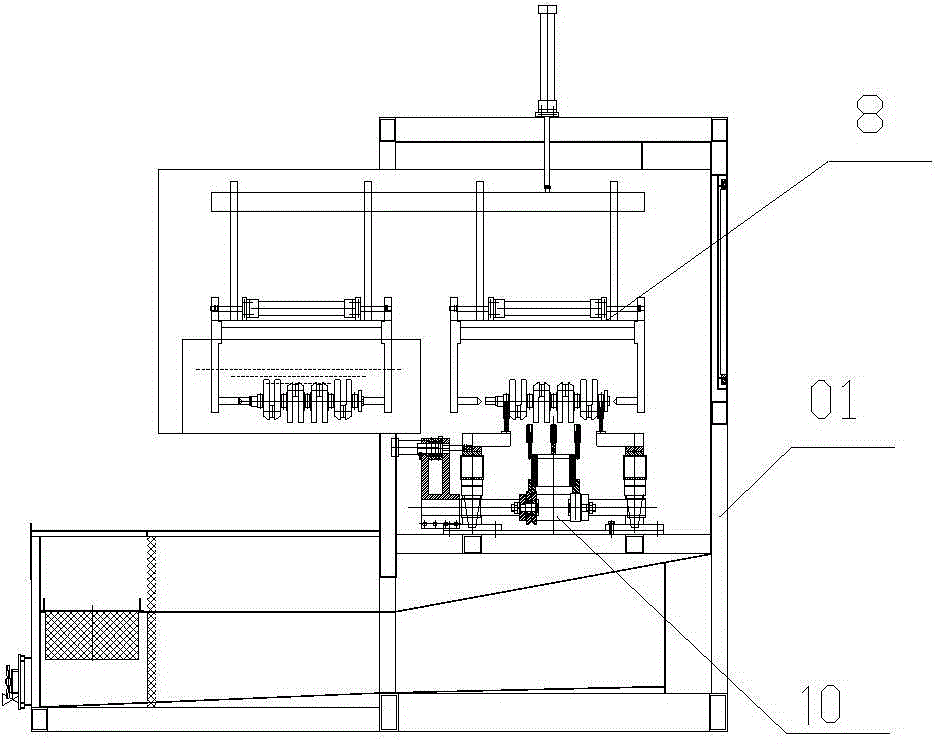

[0108] Such as Figure 1 to Figure 3 As shown, the present invention provides a rough cleaning machine for crankshafts, including a frame 001, a sealing cover (not shown) covered on the frame 001, and a feeding station sequentially arranged on the frame 001 according to the cleaning sequence 002, the first surface cleaning system 003, the surface ultrasonic cleaning system 004, the second surface cleaning system 005, the oil passage cleaning system 006, the surface rinsing system 007, the surface drying system 008, the hot air drying system 009, the ultrasonic oil immersion system 010 , wind cutting oil blowing system 011 and unloading station 012.

[0109] The first surface cleaning system 003, the second surface cleaning system 005, and the surface rinsing system 007 are equipped with spray cleaning rooms, ultrasonic cleaning systems, surface drying systems 008, hot air drying systems 009, ultrasonic oil immersion systems 010, wind cutting blowing The oil system 011 is resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com