Intelligent continuous high-temperature disinfection system

A high-temperature disinfection and continuous technology, applied in heating, irradiation, etc., can solve the problems of inability to use intelligent assembly line production and low efficiency, and achieve the effects of eliminating pesticide residues, saving fuel costs, and ensuring safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

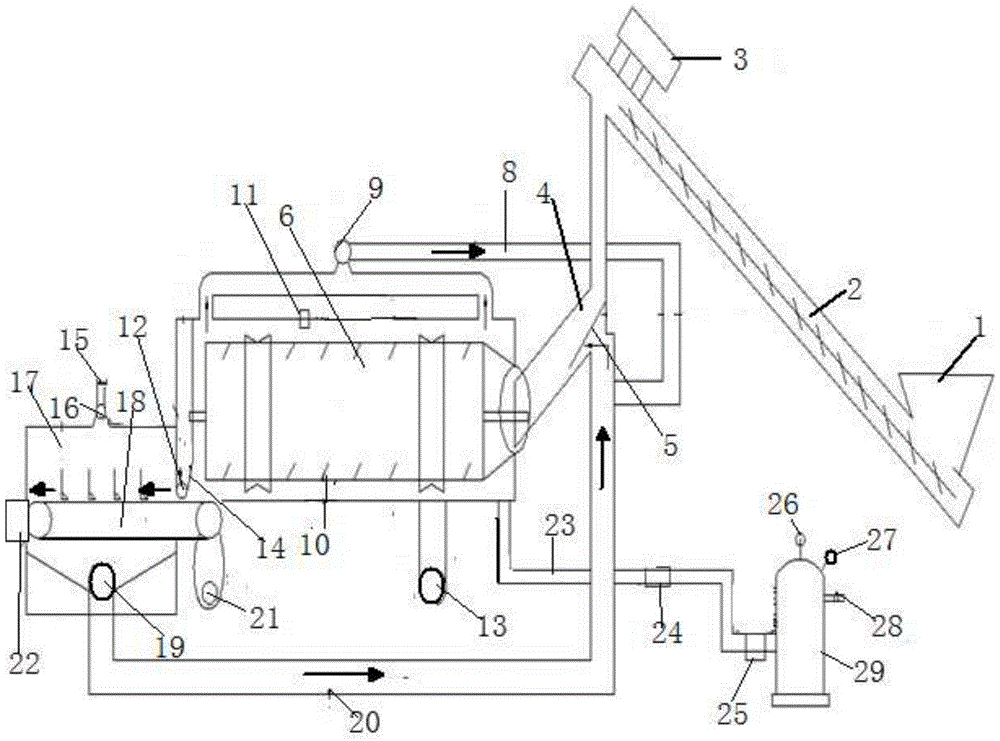

[0014] Such as figure 1 As shown, the intelligent continuous high-temperature disinfection system of the present invention includes a feeding machine, a sterilizing machine, a strong cooling machine, and a steam generator. The substrate feed port 1 is connected to one end of the conveying device 2, and the frequency conversion motor 3 and one end of the inlet pipe 4 are connected to the other end of the conveying device 2;

[0015] The disinfection machine includes a drum 6, a first heat recovery air duct 8, a first circulation fan 9, a material guide plate 10, a first temperature sensor 11, a movable cover plate 12, a first deceleration and frequency conversion motor 13, and an impeller type material sensor 14, The other end of the inlet pipe 4 is connected to one end of the drum 6 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com