Preparation method of cane sugar powder essence special for betel nuts and cane sugar base special for cane sugar powder essence

A powder essence and sucrose technology, which is applied in the field of preparation of betel nut sucrose powder essence, can solve the problems of high temperature sweetness, unsatisfactory aroma and sweetening effects, complicated process, etc., and achieve the effect of rich and full aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] According to the formula 1, the aroma raw materials are put into the batching tank to obtain the mixture 1.

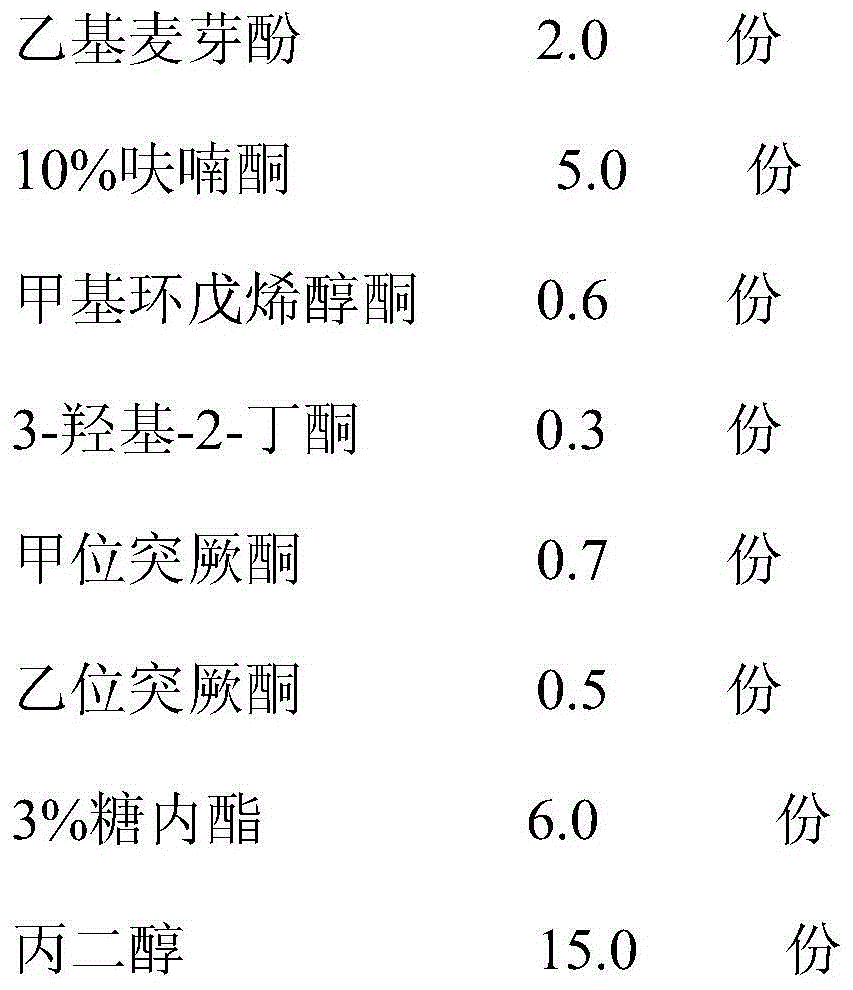

[0026] Recipe 1:

[0027]

[0028] Stir the mixture 1 evenly to obtain the sucrose base 1. According to formula 2, mix ingredients in a batching tank and stir evenly to obtain mixture 2.

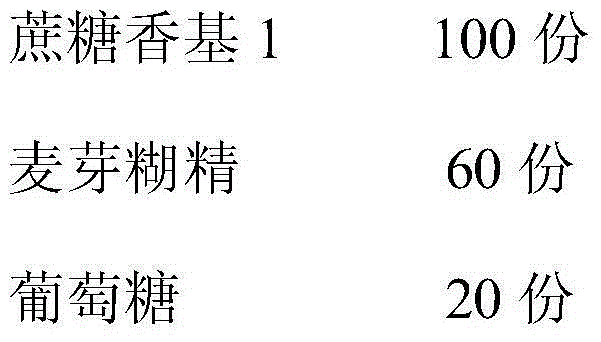

[0029] Recipe 2:

[0030]

[0031]

[0032] Pass the mixture 2 through the homogenizer, the high pressure gauge of the homogenizer is 28MPa, and the low pressure gauge is 7MPa.

[0033] After homogenization, the powder spraying solution 1 is obtained. The powder spraying liquid 1 is spray-dried, the hot air inlet temperature of the spray drying tower is 220 degrees centigrade, and the outlet temperature is 105 degrees centigrade. After spray drying, the special sucrose powder essence for betel nut can be obtained which combines sucrose aroma and sucrose taste.

[0034] Implementation column two

[0035] According to the formula 3, the fragrance raw materials are...

Embodiment 5

[0062] According to the formula 9, the fragrance raw materials are put into the batching tank to obtain the mixture 9.

[0063] Recipe 9:

[0064]

[0065]

[0066] Stir the mixture 9 evenly to obtain the sucrose base 9. According to formula 10, mix ingredients in a batching tank and stir evenly to obtain mixture 10.

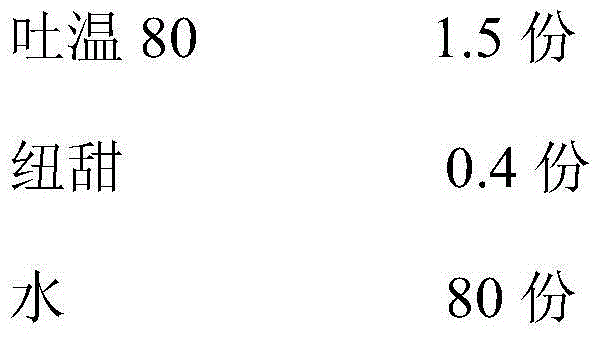

[0067] Recipe 10:

[0068]

[0069] Pass the mixture 10 times through the homogenizer, the high pressure gauge of the homogenizer is 30MPa, and the low pressure gauge is 3MPa.

[0070]After homogenization, the powder spraying solution 5 is obtained. The powder spraying liquid 5 is spray-dried, the hot air inlet temperature of the spray drying tower is 180 degrees centigrade, and the outlet temperature is 90 degrees centigrade. After spray drying, the special sucrose powder essence for betel nut can be obtained which combines sucrose aroma and sucrose taste.

Embodiment 6

[0072] According to the formula 11, the aroma raw materials are put into the batching tank to obtain the mixture 11.

[0073] Recipe 11:

[0074]

[0075]

[0076] Stir the mixture 11 evenly to obtain the sucrose base 11. According to formula 12, mix ingredients in a batching tank and stir evenly to obtain mixture 12.

[0077] Recipe 12:

[0078]

[0079] The mixture 12 is passed through the homogenizer, the high pressure gauge of the homogenizer is 55MPa, and the low pressure gauge is 15MPa.

[0080] After homogenization, the powder spraying solution 6 is obtained. The powder spraying liquid 6 is spray-dried, the hot air inlet temperature of the spray drying tower is 230 degrees Celsius, and the outlet temperature is 130 degrees Celsius. After spray drying, the special sucrose powder essence for betel nut can be obtained which combines sucrose aroma and sucrose taste.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com