Low-salt low-nitrite Chinese cabbage fermentation processing technology

A technology of low nitrite and processing technology, applied in the field of processing technology of low-salt and low-nitrite fermented cabbage, can solve the problems of prolonging the fermentation cycle, increasing the processing cost of fermented cabbage, reducing production efficiency, etc., so as to simplify procedures and reduce The effect of cost, pure taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

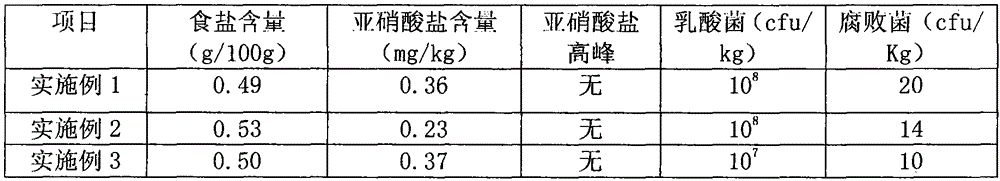

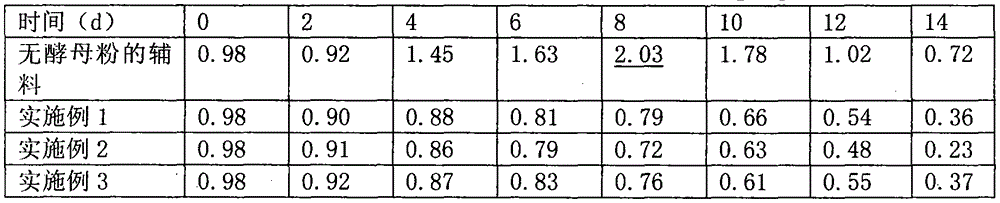

Embodiment 1

[0014] Embodiment 1 (taking 1000 grams of Chinese cabbage as an example)

[0015] The processing technology of low-salt and low-nitrite fermented cabbage includes the following processing steps: (1) wash and drain 1000 grams of cabbage, smear the fermentation auxiliary material between each layer of cabbage leaves, put In a fermentation container, compact it; seal the fermentation container; at a temperature of 20-25°C, the fermentation time shall not be less than two weeks; or at a temperature of 15-20°C, the fermentation time shall not be less than one month; (3 ) fermented cabbage is obtained after the fermentation is completed; (4) the fermented cabbage is processed, packaged and then sterilized to obtain fermented cabbage products. The preparation method of described fermentation auxiliary material: with 30 gram salt (3%), 40 gram glucose (4%), 30 gram capsicum (3%), 40 gram mashed garlic (3%), 20 gram tomato sauce (2%) ), 10 grams of shrimp paste (1%), 4 grams of dry ye...

Embodiment 2

[0016] Embodiment 2 (taking 1000 grams of Chinese cabbage as an example)

[0017] The processing technology of low-salt and low-nitrite fermented cabbage includes the following processing steps: (1) wash and drain 1000 grams of cabbage, smear the fermentation auxiliary material between each layer of cabbage leaves, put In a fermentation container, compact it; seal the fermentation container; at a temperature of 20-25°C, the fermentation time shall not be less than two weeks; or at a temperature of 15-20°C, the fermentation time shall not be less than one month; (3 ) fermented cabbage is obtained after the fermentation is completed; (4) the fermented cabbage is processed, packaged and then sterilized to obtain fermented cabbage products. The preparation method of described fermentation auxiliary material: with 30 gram salt (3%), 30 gram glucose (3%), 40 gram capsicum (4%), 40 gram mashed garlic (4%), 30 gram tomato sauce (3%) ), 15 grams of shrimp paste (1.5%), and 3 grams of ...

Embodiment 3

[0018] Embodiment 3 (taking 1000 grams of Chinese cabbage as an example)

[0019] The processing technology of low-salt and low-nitrite fermented cabbage includes the following processing steps: (1) wash and drain 1000 grams of cabbage, smear the fermentation auxiliary material between each layer of cabbage leaves, put In the fermentation container, compact; seal the fermentation container; at a temperature of 20-25°C, the fermentation time shall not be less than two weeks; or at a temperature of 15-20°C, the fermentation time shall not be less than one month; (3 ) fermented cabbage is obtained after the fermentation is completed; (4) the fermented cabbage is processed, packaged and then sterilized to obtain fermented cabbage products. The preparation method of described fermentation auxiliary material: with 30 gram salt (3%), 20 gram glucose (2%), 50 gram capsicum (5%), 50 gram mashed garlic (5%), 1 gram tomato sauce (1%) ), 2 grams of shrimp paste (2%), and 2 grams of dry y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com