Tea yoghurt and preparation method thereof

A technology of yogurt and tea, which is applied in the direction of milk preparations, dairy products, applications, etc., can solve the problems of low source of nutrients, low nutritional value, and poor health care effects, and achieve the effects of convenient drinking, stable taste, and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

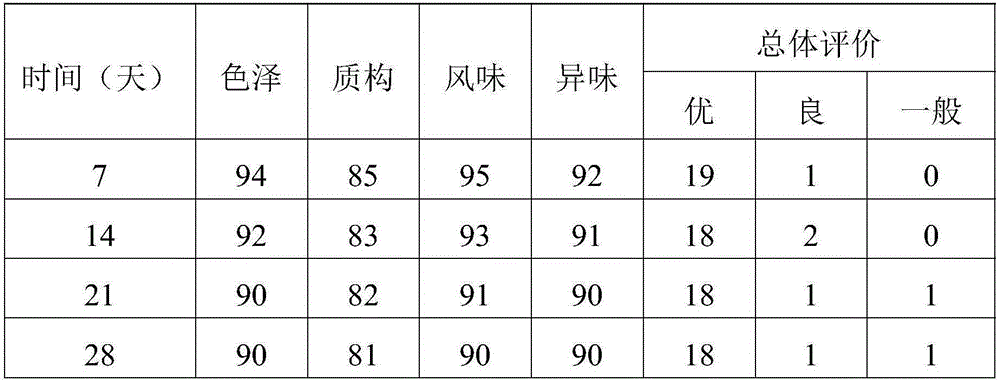

Embodiment 1

[0038] Homogenize the reconstituted milk, take the homogenized reconstituted milk that accounts for 25% of the total mass of the homogenized reconstituted milk, preheat it to 75°C, add 6% fructose syrup and 0.6% tea leaves to the total mass of the final product and 0.07% vitamin C, leached at 75°C for 28 minutes, filtered to remove the filter residue, mixed the filtrate with the remaining homogeneous reconstituted milk, sterilized at 80°C for 10 minutes, cooled to 38°C, and added starter Streptococcus thermophilus 1× 10 6 cfu / mL, Lactobacillus bulgaricus 1×10 6 cfu / mL fermented for 8 hours.

Embodiment 2

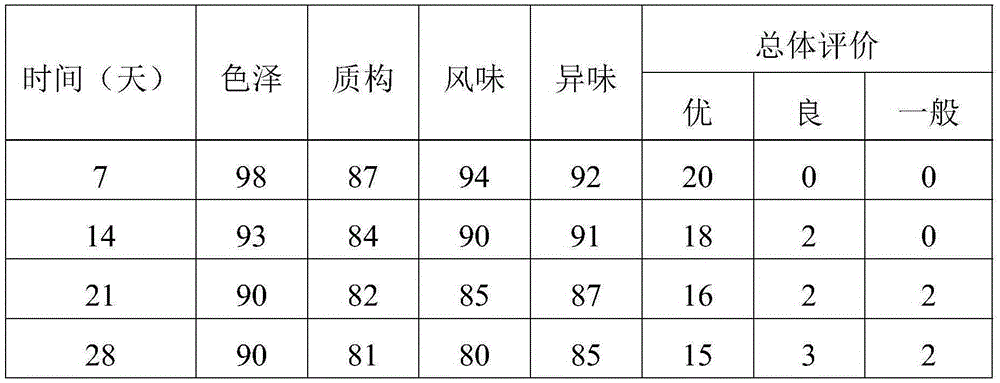

[0040] Homogenize the raw milk, take the homogenized raw milk that accounts for 20% of the total mass of the homogenized raw milk, preheat it to 70°C, add 8% of sucrose, 0.5% of tea and 0.05% of the total mass of the final product % vitamin C, leached for 30 minutes at 75°C, filtered to remove the filter residue, mixed the filtrate with the remaining homogenized raw milk, sterilized at 90°C for 5 minutes, cooled to 42°C, and added starter Streptococcus thermophilus 4×10 6 cfu / mL fermented for 6 hours.

Embodiment 3

[0042] Homogenize the raw milk, take the homogenized raw milk that accounts for 30% of the total mass of the homogenized raw milk, preheat it to 72°C, add 7% sucrose, 0.4% tea, 0.03 % vitamin E and 0.03% vitamin C, extract at 70°C for 40 minutes, filter to remove the filter residue, mix the filtrate with the remaining homogenized raw milk, sterilize at 90°C for 7 minutes, cool to 42°C, add starter cheese milk Bacillus 2×10 6 cfu / mL fermented for 24 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com