Multifunctional high-efficiency sintering cup experimental device and method

An experimental device and sintering cup technology, which is applied in chemical analysis using combustion, program control in instruments, and sequence/logic controllers, etc. Efficiency, reduced labor, improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

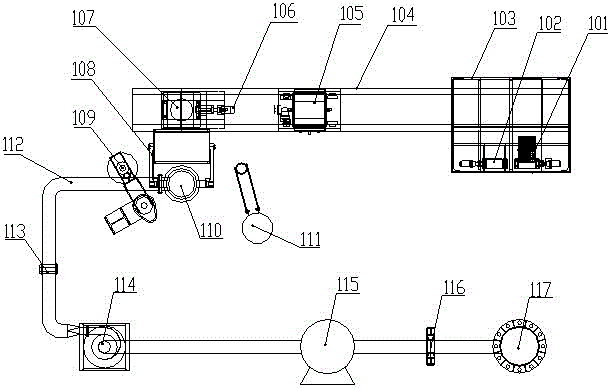

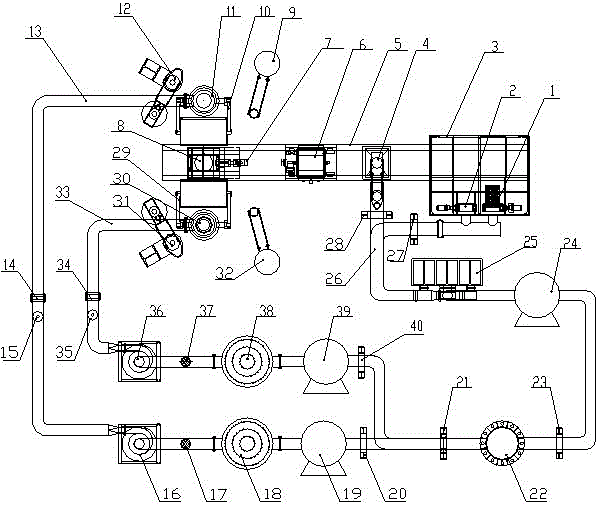

[0040] see figure 2 , a multifunctional high-efficiency sintering cup experimental device, including a mixing system (not marked in the figure), a sample divider (not marked in the figure), a screening device 1, a dropping device 2, a dropping screening system 3, and a blast cooling Device 4, track 5, sinter transport trolley 6, weighing device 7, crushing device 8, chimney 22, and two sets of independent systems: the first system is: the first ignition device 9, the first sintering cup rotary device 10 , the first sintering cup 11, the first material distribution device 12, the first smoke exhaust pipeline system 13, the first dust collector 16, the first cooler 18, the first smoke exhaust fan 19; the second system is: the second ignition device 32. The second sintering cup rotating device 29 , the second sintering cup 30 , the second materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com