Ultrasonic Fatigue Test Method for Metals with Plate Specimens Containing Equal Section Sections

A fatigue test, constant section technique, applied to the analysis of solids with sonic/ultrasonic/infrasonic waves in the same direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0136] Taking a steel material for automobile sheets as an example, it is assumed that the dimensional accuracy is well controlled during the processing of the sample.

[0137] 1. Measure the elastic modulus E=206GPa and the density ρ=7850kg / m of steel materials for automobile panels 3 .

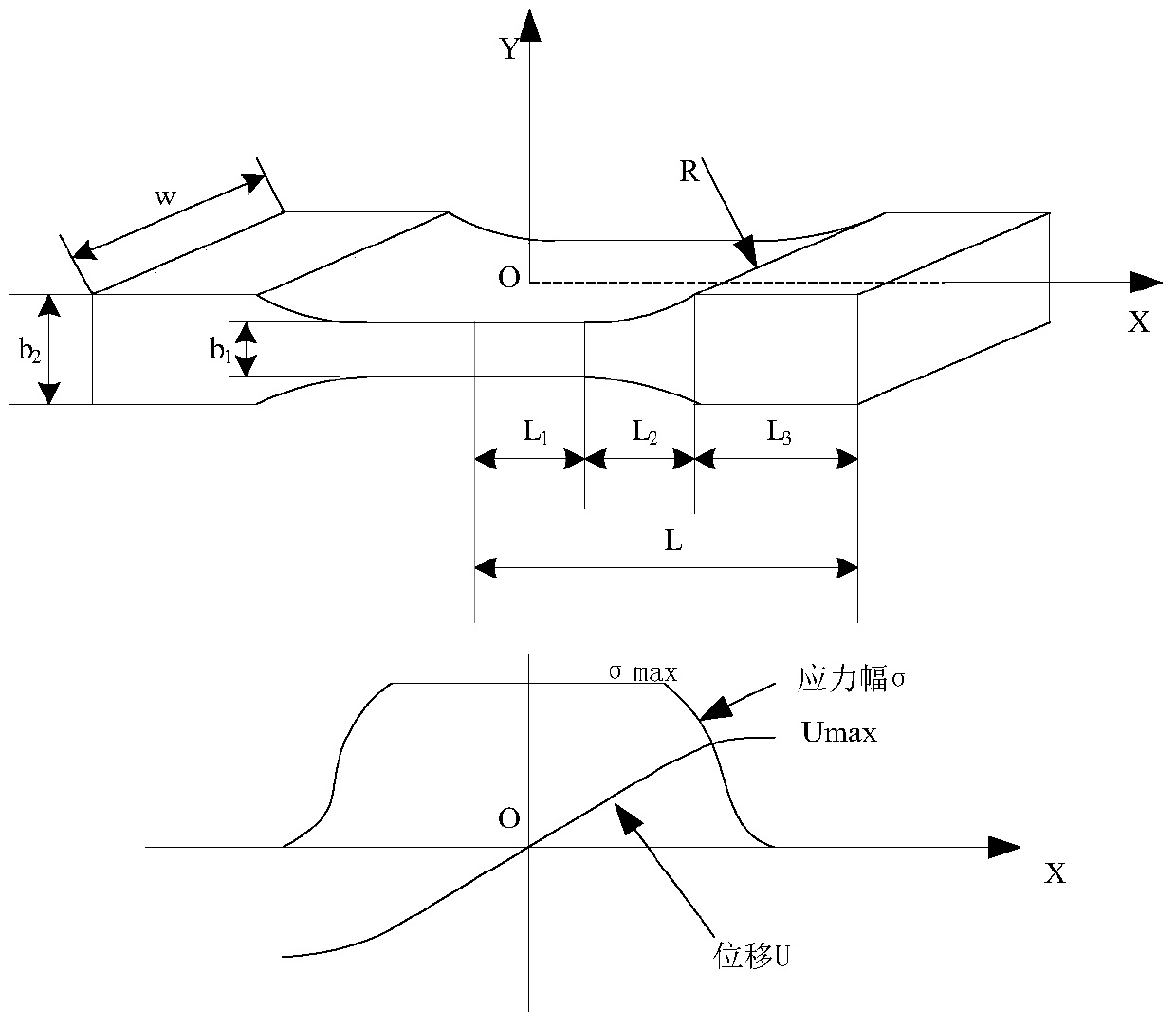

[0138] 2. Design the sample size. The preset axial tension and compression specimens are plate-shaped ultrasonic fatigue specimens with equal cross-sections, such as image 3 shown. First draw up its size parameters, L 1 =12.5mm, L 2 =20mm,b 1 = 3mm, b 2 = 10mm, b 1 is the thickness of the equal section section of the plate, b 2 is the thickness at both ends of the plate, L 1 is half of the length of the constant section section of the plate, L 2 is the variable section length of the plate. When calculating, convert all known parameters into mm, g, ms dimensional units, and calculate the length L at both ends of the sample from the calculation formula of the length at both ends of...

Embodiment 2

[0144] Taking the same steel material for automobile sheets as in Example 1 as an example, it is assumed that the dimensional accuracy is not well controlled during the processing of the sample, and the actual size of the sample deviates greatly from the design size due to surface grinding after the sample is processed .

[0145] 1. Measure the elastic modulus E=206GPa and the density ρ=7850kg / m of steel materials for automobile panels 3 .

[0146] 2. Design the sample size. The preset axial tension and compression specimens are plate-shaped ultrasonic fatigue specimens with equal cross-sections, such as image 3 shown. First draw up its size parameters, L 1 =12.5mm, L 2 =20mm,b 1 = 3mm, b 2 = 10mm, b 1 is the thickness of the equal section section of the plate, b 2 is the thickness at both ends of the plate, L 1 is half of the length of the constant section section of the plate, L 2 is the variable section length of the plate. When calculating, convert all known p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com