Solid material thermal diffusion coefficient measuring device and measuring method thereof

A technology of thermal diffusivity and solid materials, which is applied in the field of measuring the thermal properties of solid materials, and can solve the problems that the pressure regulation cannot be carried out in real time, the accuracy is low, and it is not suitable for measuring materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

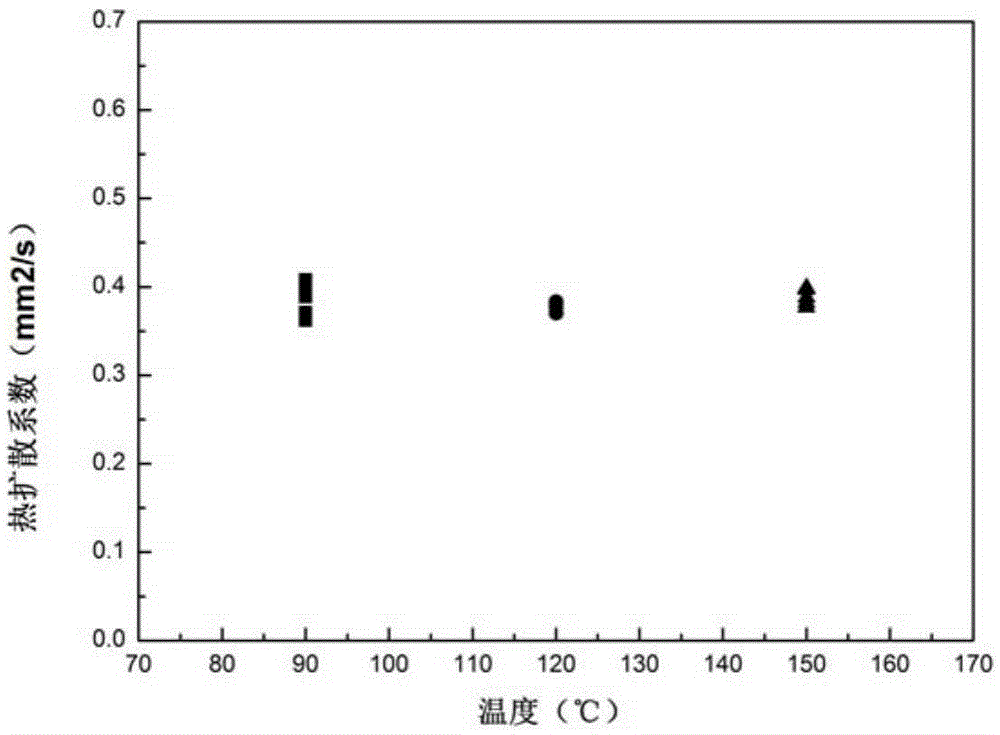

Image

Examples

Embodiment Construction

[0029] see figure 1 and 2 , The measuring device described in this embodiment includes a heating device 1, a loading device 2, an infrared detector 3, a computer control and acquisition system 4, a stepping motor control system 5, and a pressure display device 6, wherein:

[0030] The heating device 1 uses an infrared laser with a wavelength of 1064nm to temporarily and uniformly heat the lower surface of the sample. During the test, it is necessary to ensure that the axis of the infrared laser coincides with the axis of the loading device 2, so as to ensure that the infrared laser can vertically heat the sample.

[0031] The connector 7 of the loading device 2 is connected with the stepper motor control system 5 through an electrical signal, and is used to receive the output electrical signal of the stepper motor control system 5. The pressure sensor 11 at the bottom of the connector 7 is connected with the pressure display device 6 through a circuit, It is used to display ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com