Cement fineness negative pressure sieve analysis apparatus

A fineness and negative pressure technology, applied in the field of cement fineness testing equipment, can solve the problems of burning out the motor, heavy workload, polluting the environment, etc., and achieve the effect of prolonging the service life, reasonable structure and low noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

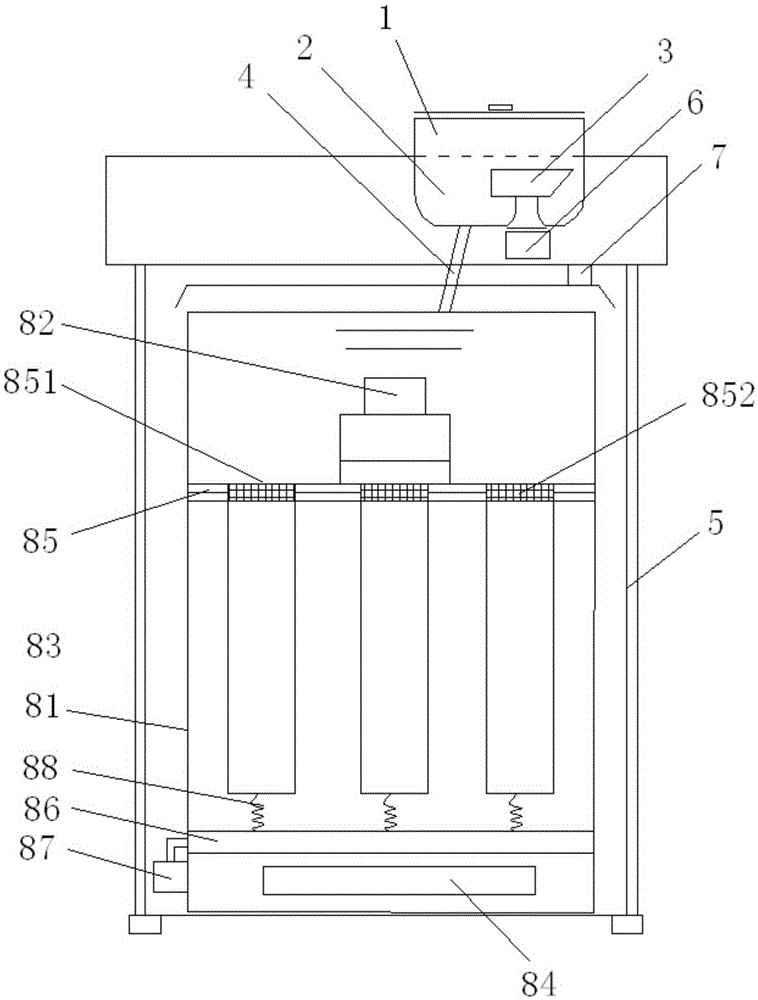

[0041] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0042] In order to achieve the purpose of the present invention, in some embodiments of the cement fineness negative pressure sieving device,

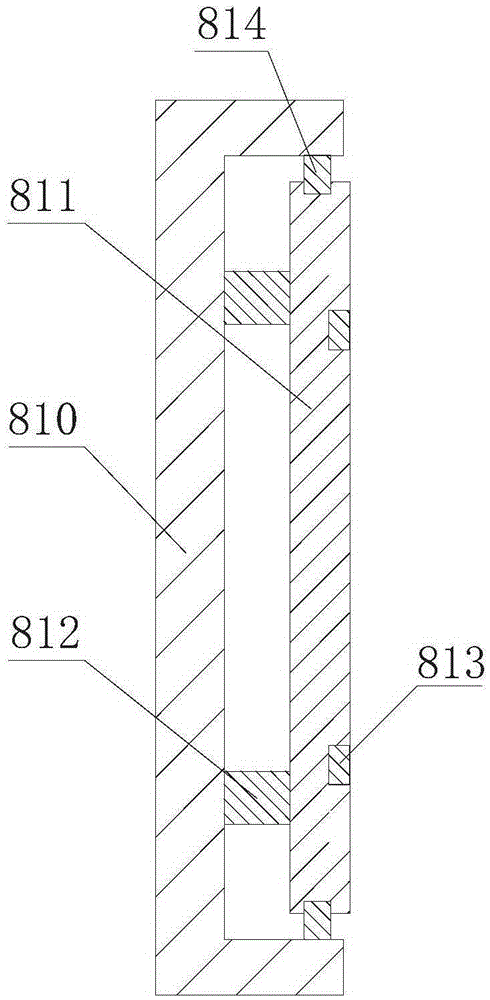

[0043] Such as Figure 1-Figure 2 As shown, the cement fineness negative pressure screening device includes: test sieve 1, sieve seat 2, air nozzle 3, suction pipe 4, bracket 5, micro-motor 6, cyclone 7 and filter 8, filter 8 includes: box body 81 and the motor 82, filter bag 83 and ash hopper 84 that are arranged in the casing 81;

[0044] A connection plate 85 is provided between the motor 82 and the filter bag 83, the connection plate 85 is provided with one or more connection holes 851, and the filter bag 83 is arranged below the connection holes 851;

[0045] A vibration frame 86 is arranged between the ash hopper 84 and the filter bag 83. The vibration frame 86 is driven by a vibration drive d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com