Nano fiber parallel tensile testing system and method

A nanofiber and tensile testing technology, applied in the field of micro-nano technology, can solve the problems of uncontrollable error and large error of Young's modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

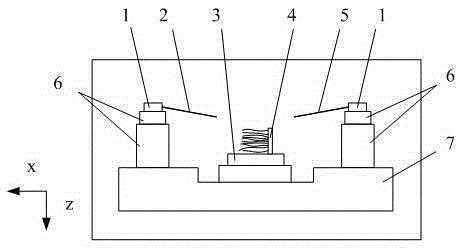

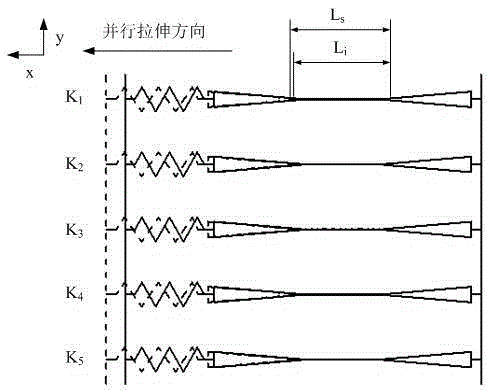

[0041] see figure 1 and figure 2 , the nanofiber parallel tensile testing system includes an electron microscope connected parallel tensile testing system, characterized in that: the electron microscope uses its excellent imaging capability to provide image data and operation basis for the parallel tensile testing system; the parallel The tensile test system includes a workbench (7), two closed-loop fast-feed mechanisms (6), two closed-loop fine-feed mechanisms (1), flexible probe sets (2), rigid probe sets (5), nanofiber culture dish (4), sample workbench (3); the two closed-loop rapid feed mechanisms (6) are installed on the left and right sides of the workbench (7) respectively, and the two closed-loop precision feed mechanisms (1) are respectively installed on the two on a closed-loop fast-feed mechanism (6); the flexible probe group (2) and the rigid probe group (5) are respectively installed on the closed-loop fine-feed mechanism (1) on the left and right sides; the na...

Embodiment 2

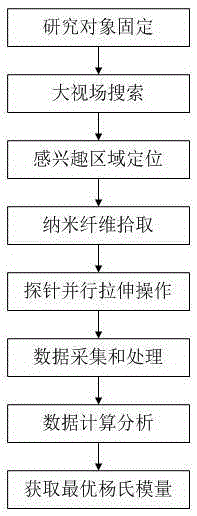

[0043] see figure 1 , image 3 and Figure 4 , this nanofiber parallel tensile test method, adopts above-mentioned system to carry out parallel tensile test, operation steps are as follows:

[0044] Step 1: Fix the research object: fix the nanofiber culture dish (4) on the sample workbench (3), push the sample workbench (3) into the electron microscope chamber for follow-up work;

[0045] Step 2: Large field of view search: use the large field of view search capability of the electron microscope to determine the position of the nanofiber on the sample workbench (3), and focus the research object until it is clearly visible;

[0046] Step 3: Locate the region of interest: move the sample worktable (3) to determine the region of interest on the research object, increase the magnification and focus on the nanofiber of interest;

[0047] Step 4: Picking up nanofibers: calibrate the region of interest according to the global position coordinates, use the parallel stretching syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com