Electronic tube member welding line fast detection device

A detection device and a technology of electronic pipe fittings, which are applied in directions such as measuring the rate of increase and deceleration of fluids, and using liquid/vacuum degrees to measure liquid tightness, etc., can solve problems such as low efficiency, inapplicability of electronic pipe fittings detection, and long time, and achieve Good repeatability, avoiding misjudgment of weld faults, and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

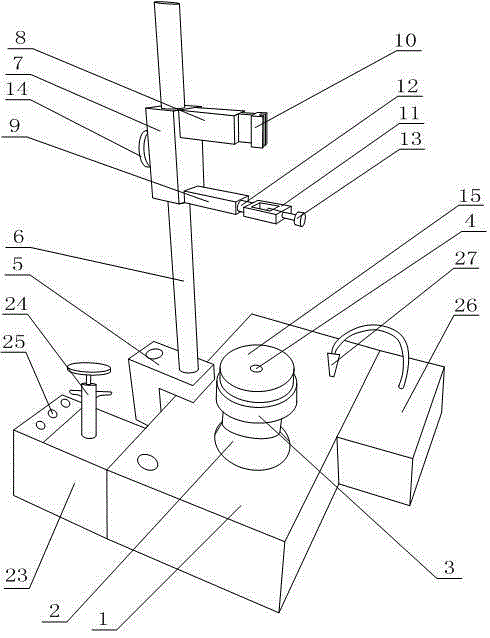

[0026] Such as figure 1As shown, a fast detection device for welds of electronic pipe fittings includes a vacuum detection table 1, on which a detection board surface 3 is connected through a closed telescopic opening 2, and a layer of rubber pad is arranged on the detection board surface 3 15. On the rubber pad 15 and the detection plate surface 3, there is an air extraction hole 4 connected with the internal vacuum of the vacuum detection table 1; it also includes a counterweight base 5, and a support rod 6 is arranged on the counterweight base 5 , a fixed body 7 that can move up and down along the support rod 6 is installed on the support rod 6, and the fixed body 7 is installed on the support rod 6 through the fastening knob 14; an upper cross arm 8 and a The lower cross arm 9 is provided with a guide block 10 on the upper cross arm 8, a guide groove is provided on the guide block 10, and a clamping mechanism is connected on the lower cross arm 9: comprising a rectangular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com