Automotive manual gear shifter convenient and fast to assemble and capable of adjusting clearance automatically

An automatic adjustment and shifter technology, applied to components with teeth, transmission device control, belt/chain/gear, etc., can solve the problem of poor shift sensitivity, increased abnormal noise, and poor operating comfort and other problems, to achieve the effect of prolonging the service life, reducing the sensitivity of shifting, and reducing the deterioration of shifting sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below with reference to the drawings and embodiments.

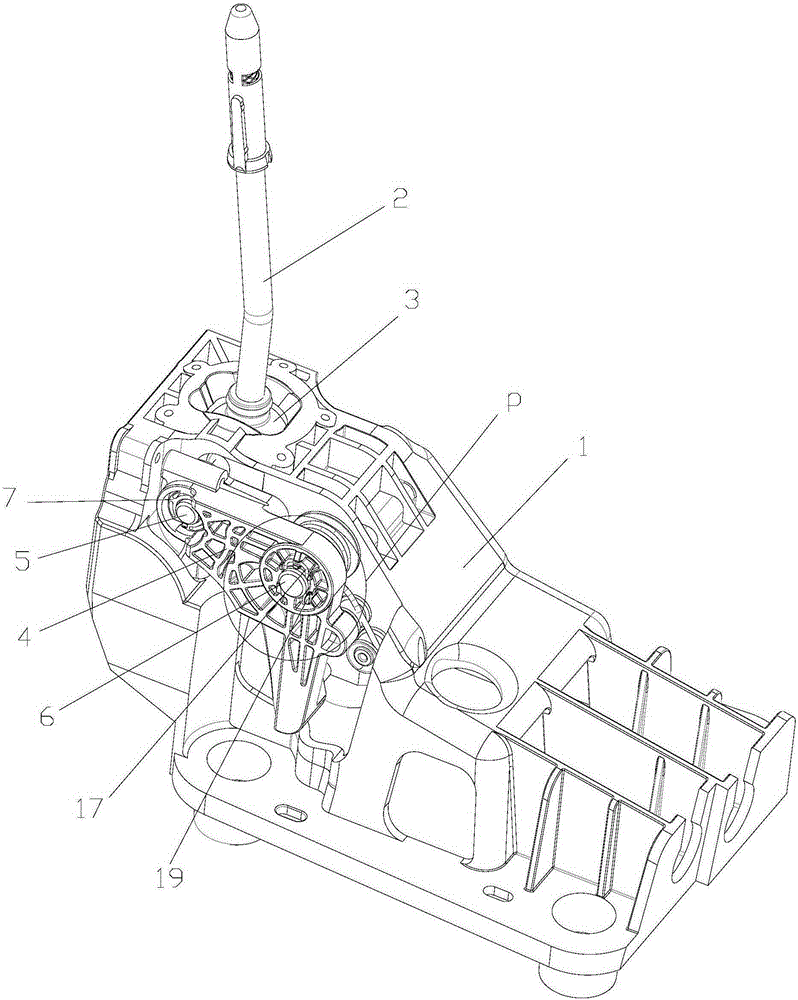

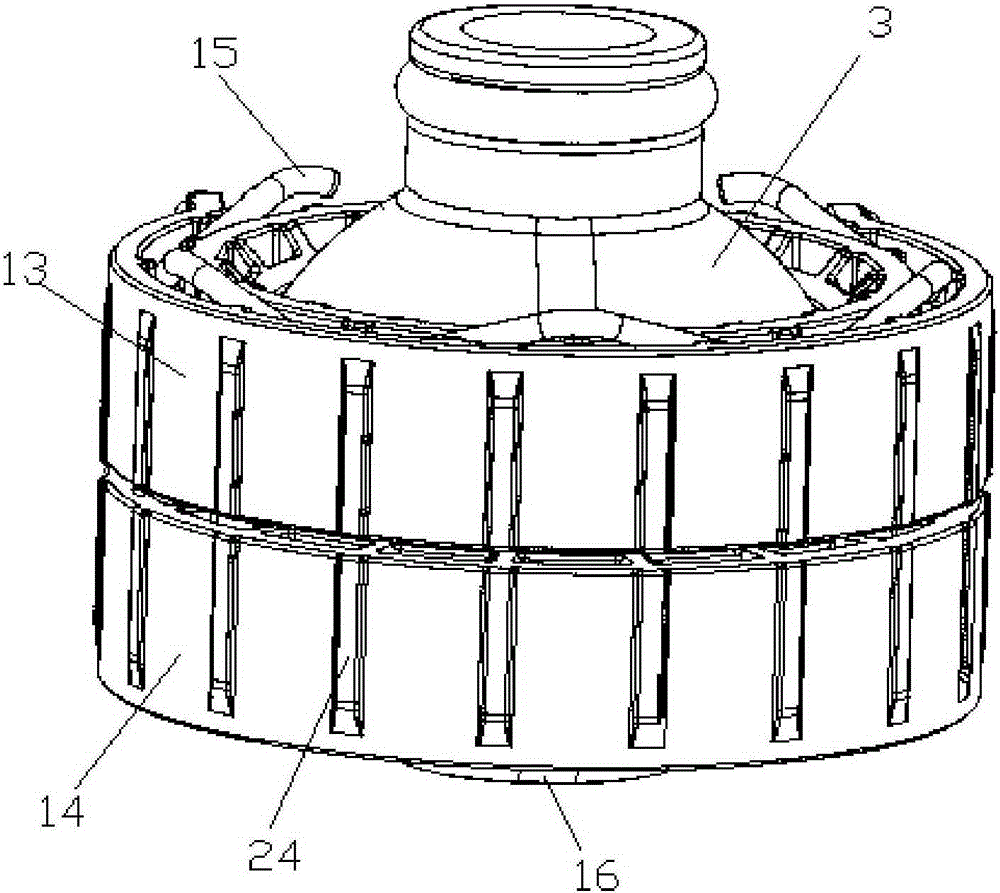

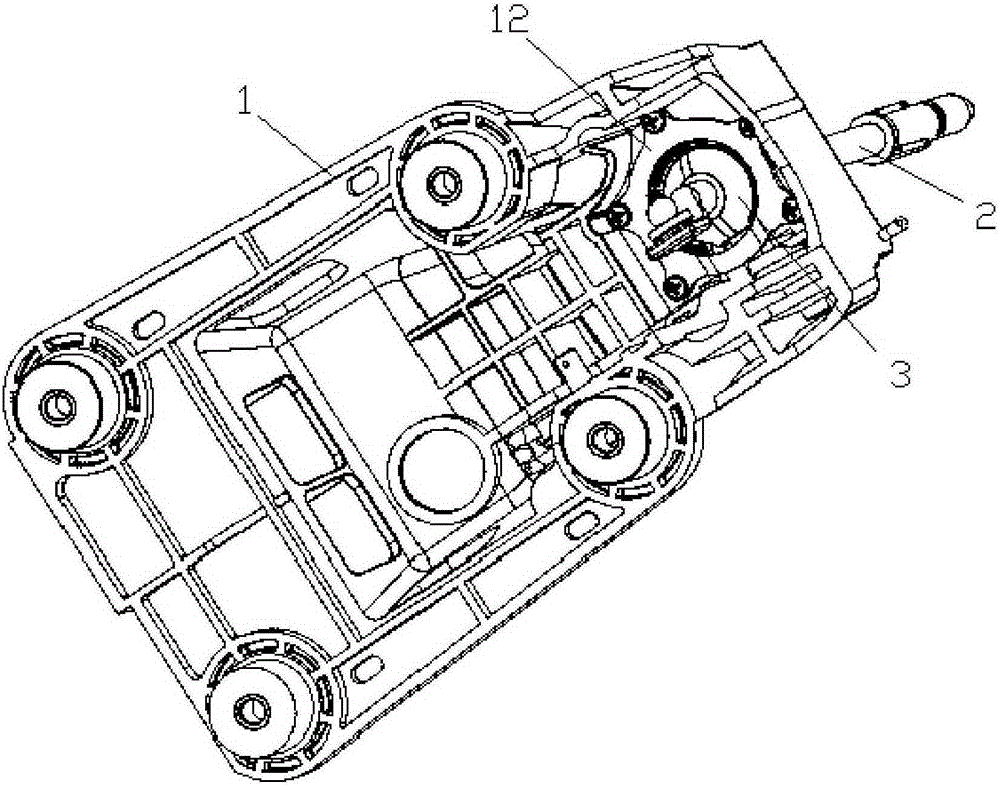

[0028] As shown in the figure, this embodiment is quick to assemble and can automatically adjust the gap of the automobile manual shifter, including a base 1, a joystick 2, a ball head 3 arranged on the joystick, a gear selector 4, and a gear selector arm. And the connecting rod 5 of the ball head and the pin 6 connecting the gear selector arm and the base,

[0029] The gear selector arm and the connecting rod are connected by a spherical bearing 7. The gear selector arm is provided with a straight hole 8 for mounting a spherical bearing, and the inner surface of the straight hole is provided with an upper stopper for fixing the spherical bearing. Block 9 and lower block 10, the upper block and the lower block are respectively provided with spherical surfaces that are rotationally matched with the upper half and the lower half of the spherical bearing;

[0030] A plurality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com