A micro-vibration active vibration isolation device installation connector and installation method thereof

A technology of active vibration isolation and installation method, applied in non-rotational vibration suppression, building components, anti-vibration and other directions, can solve the problems of difficulty in leveling, restraint, waste, etc., and achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments, but it is not intended to limit the present invention.

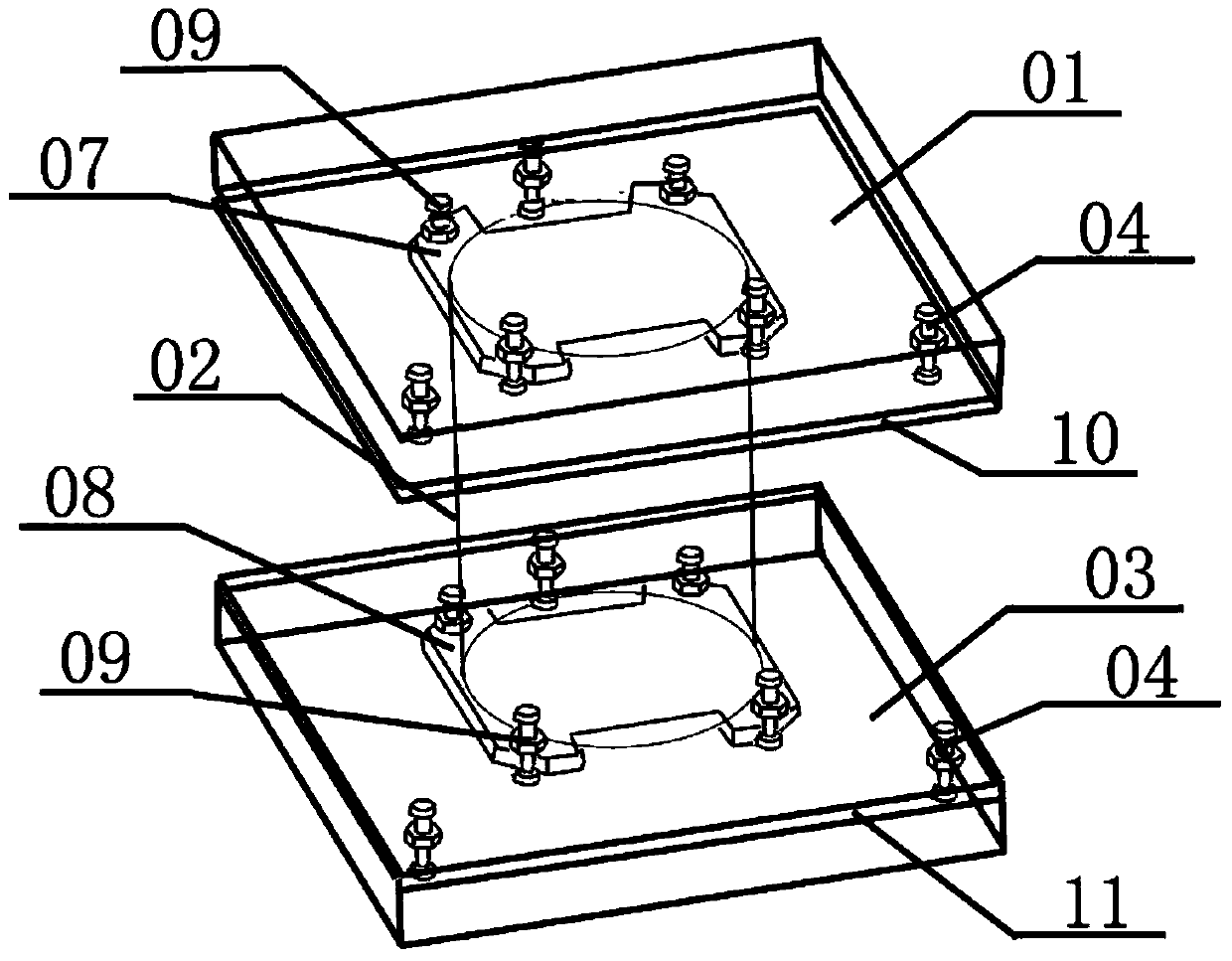

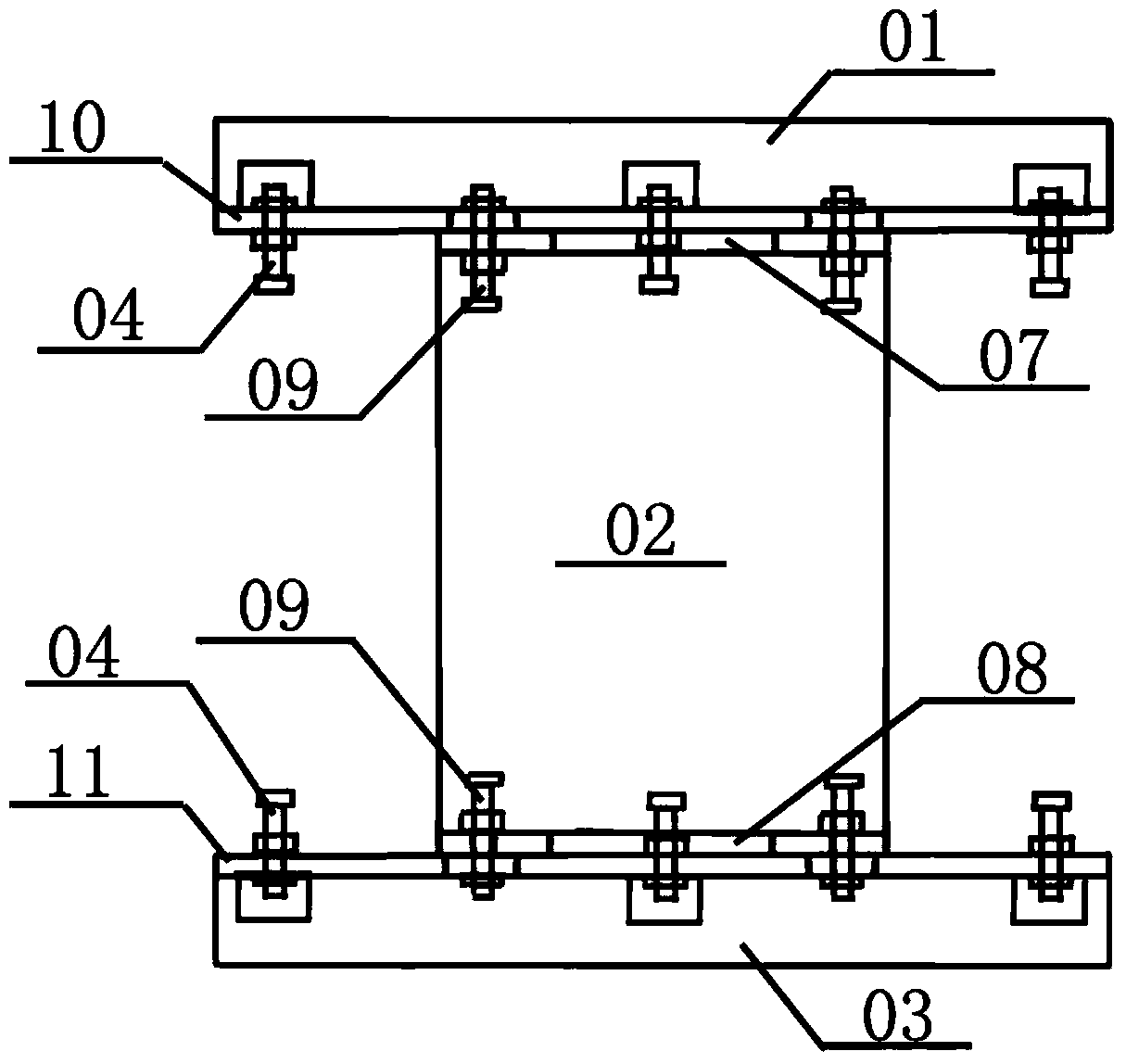

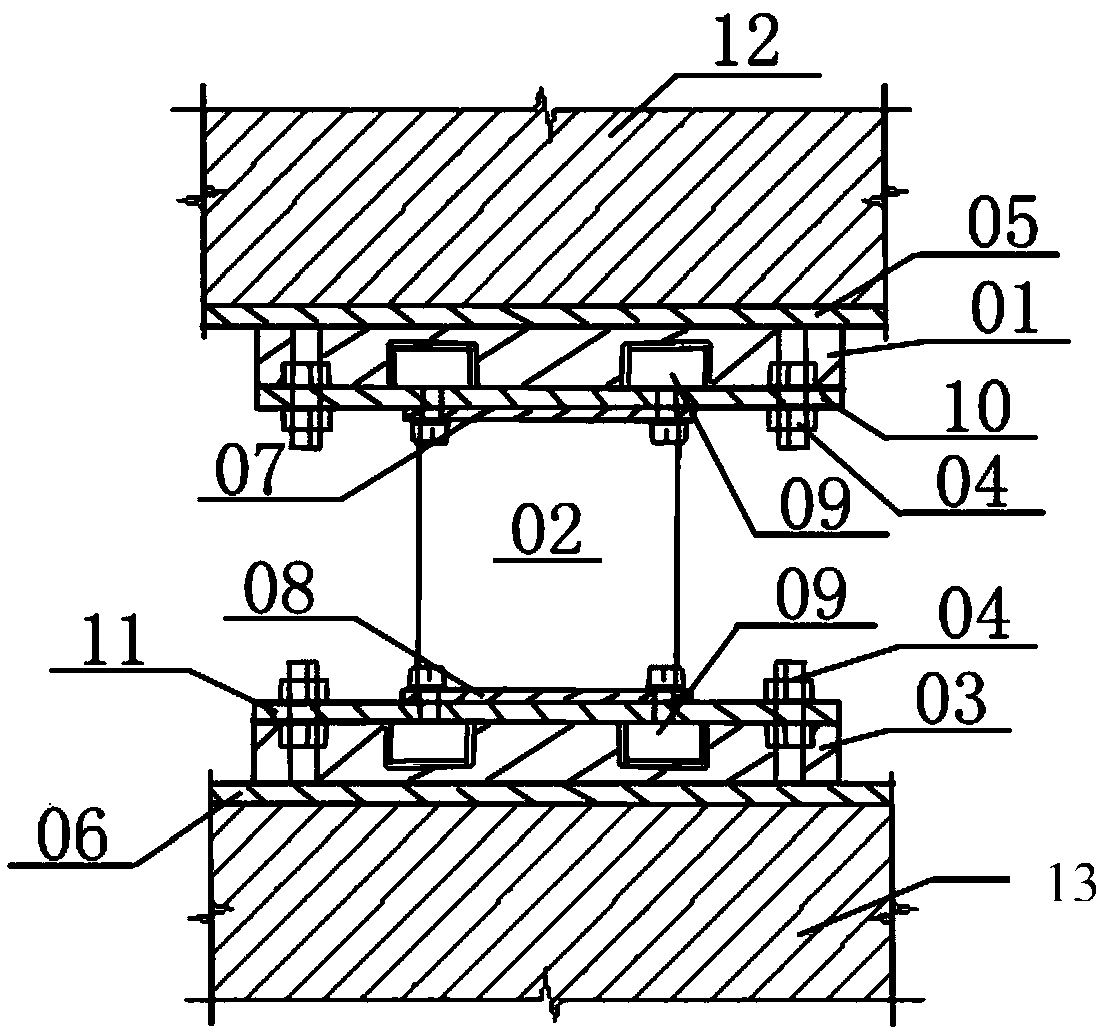

[0026] figure 1 It is a structural diagram of a mounting connector for a micro-vibration active vibration isolation device disclosed by the present invention, figure 2 It is a side view of a mounting connector for a micro-vibration active vibration isolation device disclosed by the present invention, as shown in figure 1 and figure 2 As shown, the present invention provides a micro-vibration active vibration isolation device installation connector, which includes from top to bottom: an upper glue filling tank 01, an active vibration isolation device 02 and a lower glue filling tank 03, image 3 It is a schematic diagram of the installation of a micro-vibration active vibration isolation device installation connector disclosed by the present invention, as shown in image 3 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com