Magnetic pump

A technology of magnetic pump and pump body, applied in the field of magnetic pump, can solve the problems of high brittleness and easy fracture, and achieve the effect of reducing the cost of life, avoiding easy fracture and improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

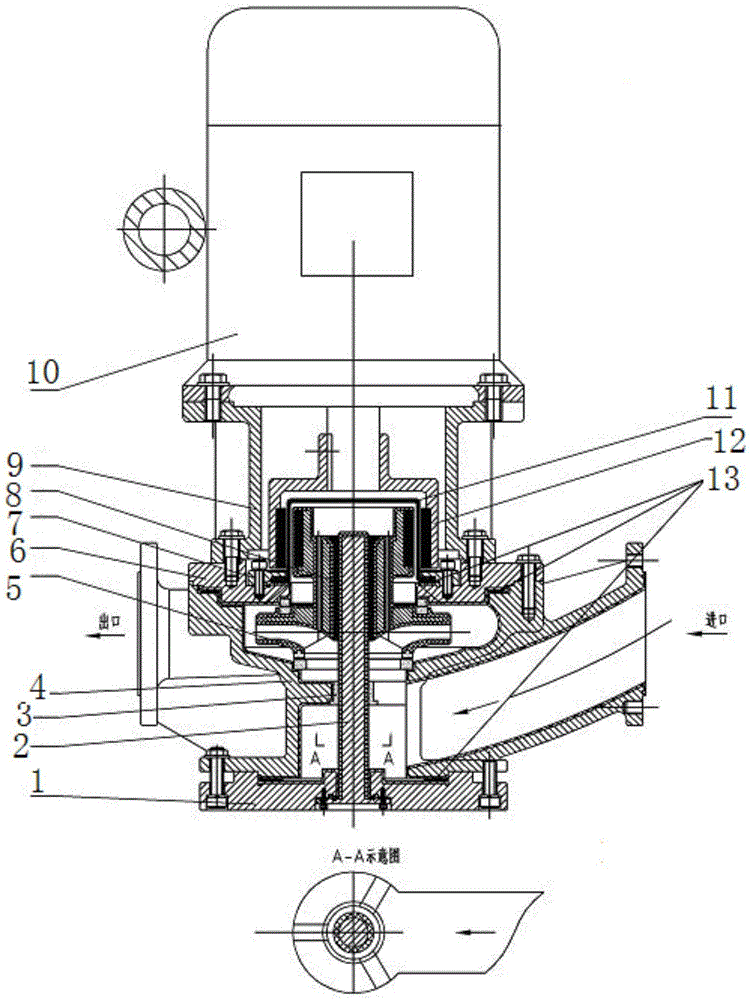

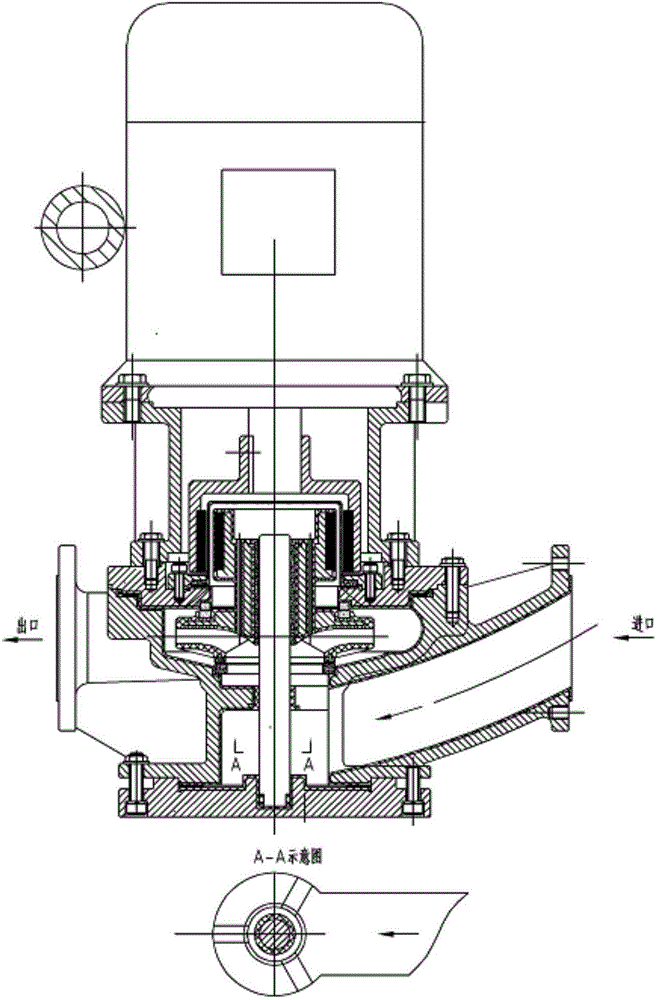

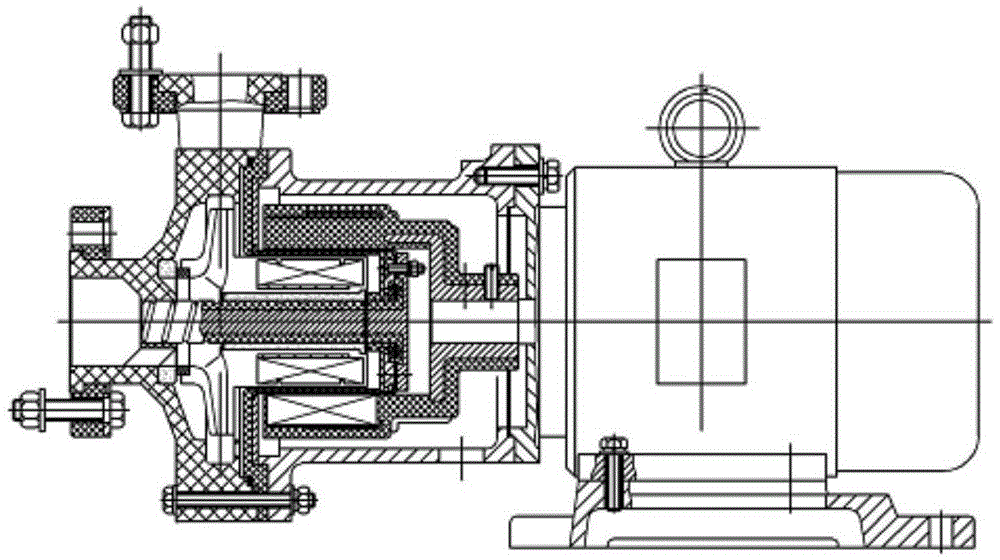

[0018] refer to figure 1 , which includes front cover 1, main shaft 2, front shaft sleeve 3, pump body 4, impeller and rotor assembly 5, rear cover 6, spacer sleeve pressure plate 7, rear shaft sleeve 8, bracket 9, motor 10, spacer sleeve combination 11 , External magnetic 12, sealing ring 13.

[0019] The main shaft is made of steel tightly packed with corrosion-resistant and wear-resistant plastic, and is fixed on the front cover with bolts through cooperation. The plastic on the outer layer of the main shaft has a lubricating and cooling spiral groove. The water inlet of the pump body and the front cover form a water inlet chamber. The body is designed with a support ring composed of support feet inside the water inlet chamber. The support ring is tightly fitted with a front bushing. The main shaft passes through the front bushing and is tightly fitted with the front bushing. The rear shaft sleeve, the impeller and the rotor assembly are set on the main shaft, and are syn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com