Petrochemical industry process pump

A technology for petrochemical and process pumps, which is applied in the field of centrifugal pumps. It can solve the problems of reducing the service life and efficiency of pumps, affecting the normal operation of pumps, and poor heat preservation effects, and achieves the effects of increased life, high reliability, and good heat preservation effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

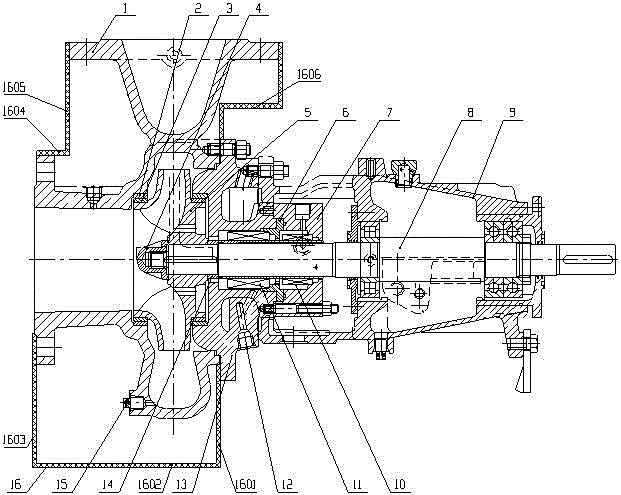

[0014] The present invention will be further described below in conjunction with accompanying drawing, but not as limiting the present invention:

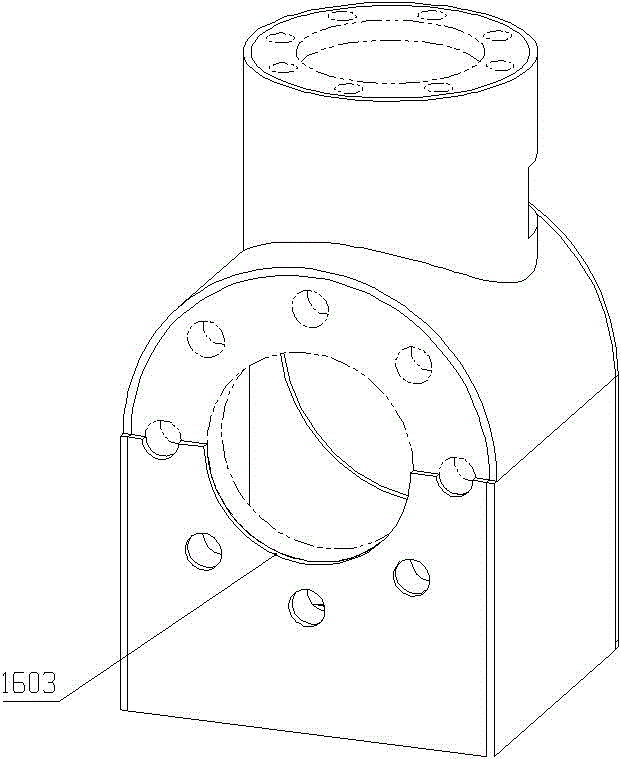

[0015] The petrochemical process pump includes a pump body 1 and an impeller 5. A pump cover 13 is installed on the right end of the pump body 1. The inlet section and the outer ring of the outlet section of the pump body 1 are provided with a pump body insulation jacket 16. The pump body is insulated. The jacket 16 is a fully enclosed structure, and the pump body insulation jacket 16 includes insulation board A1601, insulation board B1602, insulation board C1603, cylinder insulation board A1604, cylinder insulation board B1605, insulation top plate 1606, cylinder insulation board C1607, insulation Sealing plate 1608, thermal insulation bottom plate 1609, thermal insulation side plate 1610, among which the thermal insulation plate C1603 is installed on the lower half of the flange of the inlet section of the pump body 1, the lower p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com