Extracting and converting method for heat energy in coal field fire zone

A technology for fire areas and coal fields, applied in steam engine installations, machines/engines, mechanical equipment, etc., to solve the problems of heat energy dissipation, inability to extract and utilize, energy loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

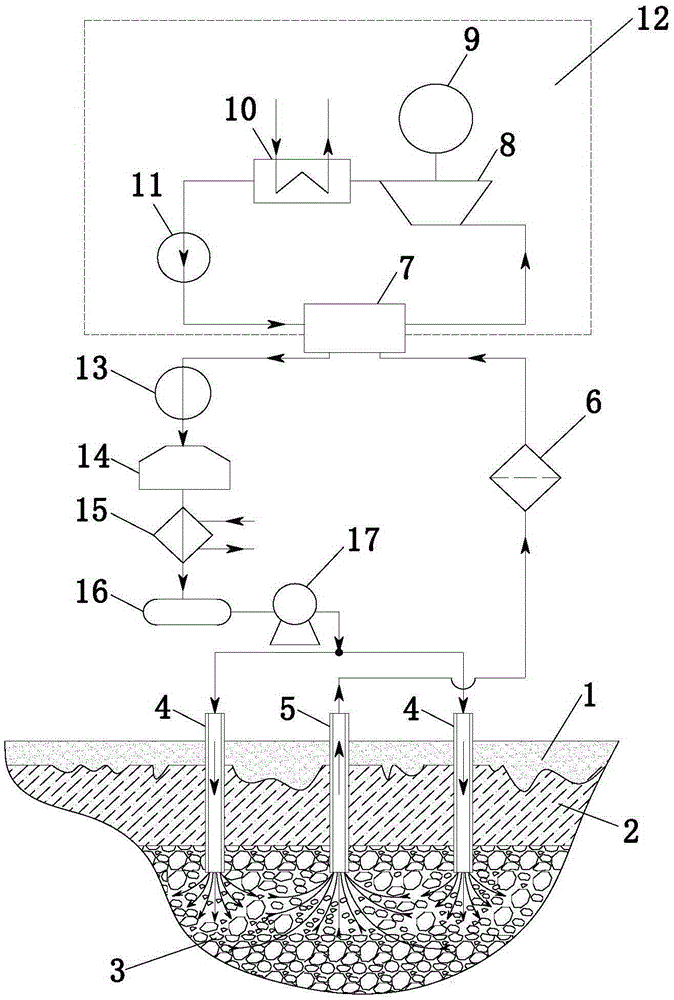

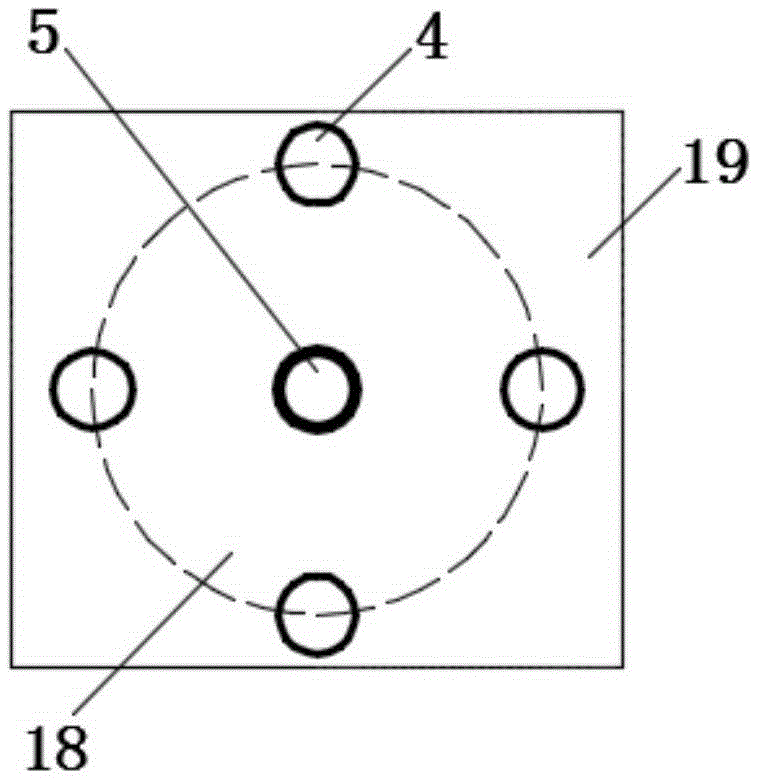

[0026] Embodiment 1: as attached figure 1 As shown, the air inlet and outlet channels such as surface fissures and subsidence pits covering the high temperature area are filled with the flame retardant filling material solidified foam 1 . Drill holes from the surface of the coalfield fire area to the underground, and drill holes through the overlying rock and soil layer 2 to the high temperature zone 3 of the underground coal and rock mass, as shown in the attached figure 2 As shown, first construct a heat medium extraction borehole 5 in the coalfield fire zone 19, and then arrange the construction heat medium injection boreholes 4 along the circumference around the extraction borehole to form a borehole control area 18, and heat medium injection The distance between the borehole and the extraction borehole is 40m, and the number of injection boreholes is 4. The low-temperature heat medium in the low-temperature gas storage tank 16 is pressurized by the gas booster pump 17 pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com