Grouting anti-bottom arch support device and support method

A technology of support device and anti-bottom arch, which is applied to shaft equipment, bolt installation, earth-moving drilling, etc., can solve problems such as poor bottom drum effect, reduce operation cost, improve support operation efficiency, and compressive strength and tensile strength improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

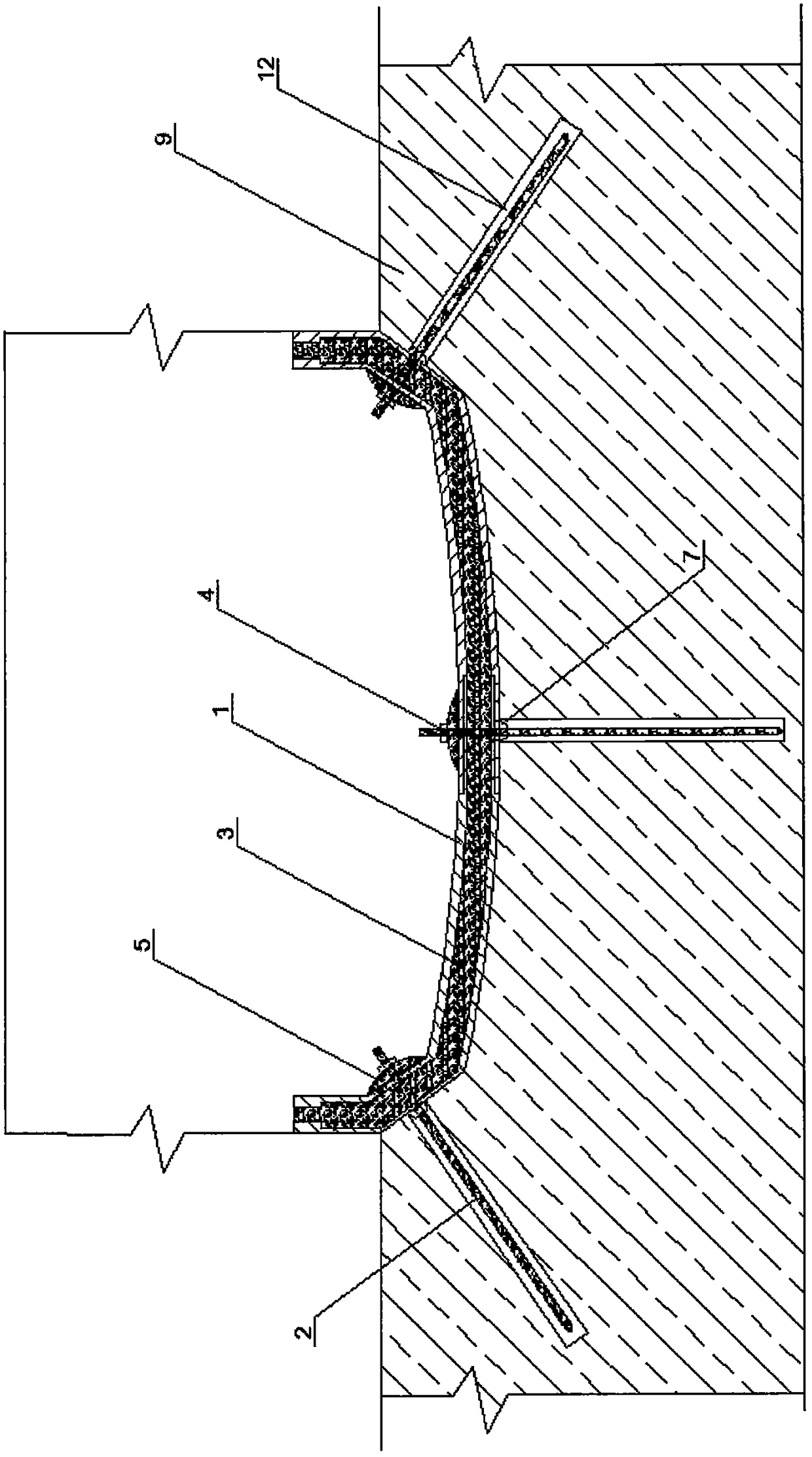

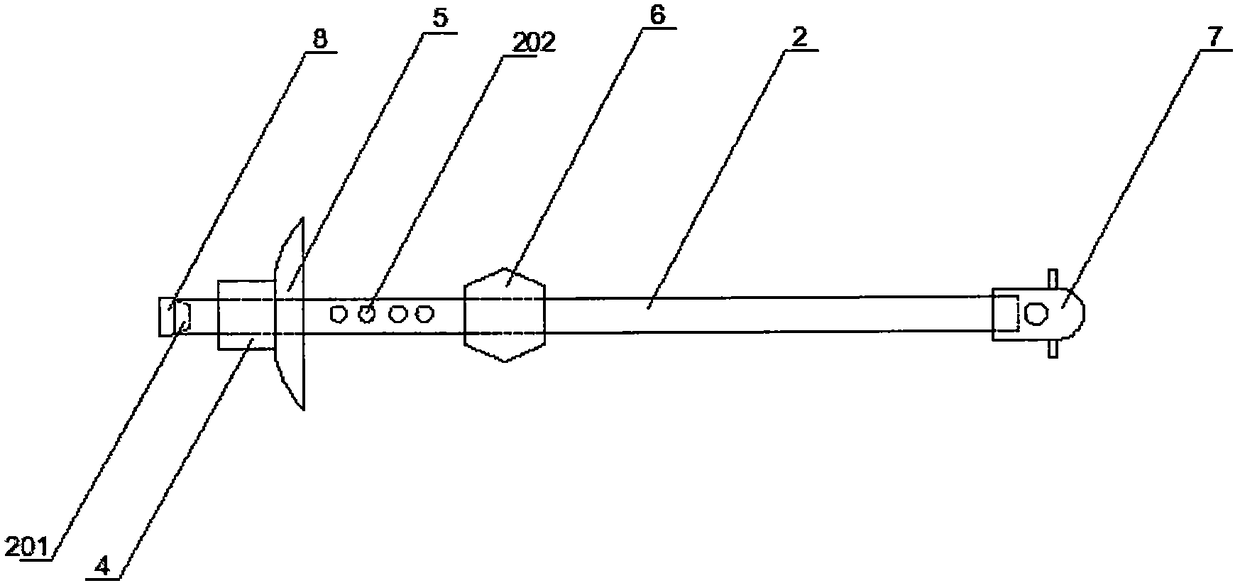

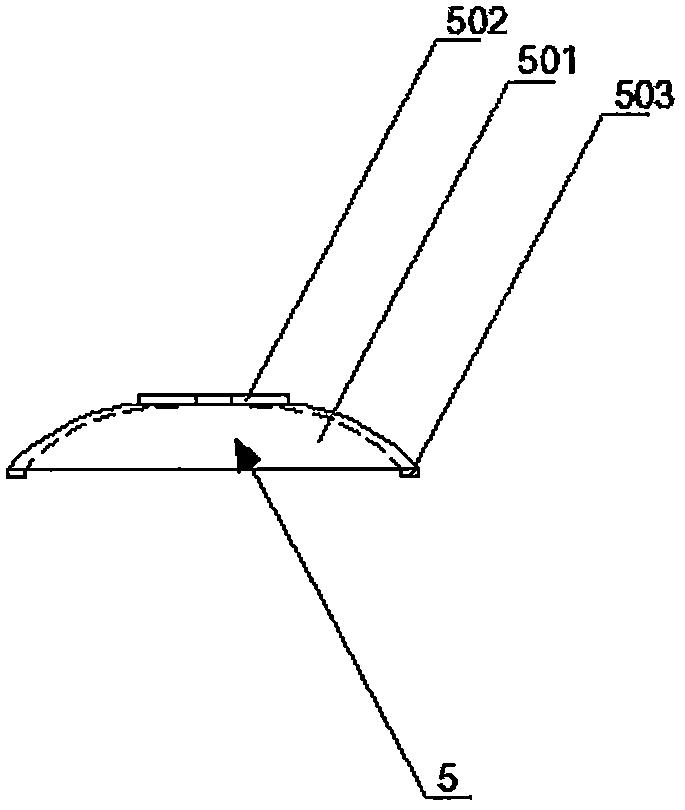

[0043] Figure 1-14 Shown is a preferred embodiment of the grouted anti-bottom arch support device of the present invention.

[0044] The grouting anti-bottom arch support device includes a reverse bottom arch hollow support body 1, a hollow anchor rod 2 and a slurry 3, and a plurality of anchor rod holes are formed on the anti-bottom arch hollow support body 1, and the hollow anchor rod Part of the rod 2 passes through the hollow support body 1 of the anti-bottom arch from the hole of the anchor rod, and the slurry 3 is poured into the hollow support body 1 of the bottom arch and the hollow anchor rod 2 .

[0045] The grouting anti-bottom arch support device in this embodiment also includes a fixing nut 4, which is threadedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com