Beam and slab connecting structure for self-restoring structures

A technology for connecting structural beams and plates, which is applied to building components, building structures, and earthquake resistance, achieving the effects of convenient and fast installation, good technical and economic benefits, and convenient access to materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

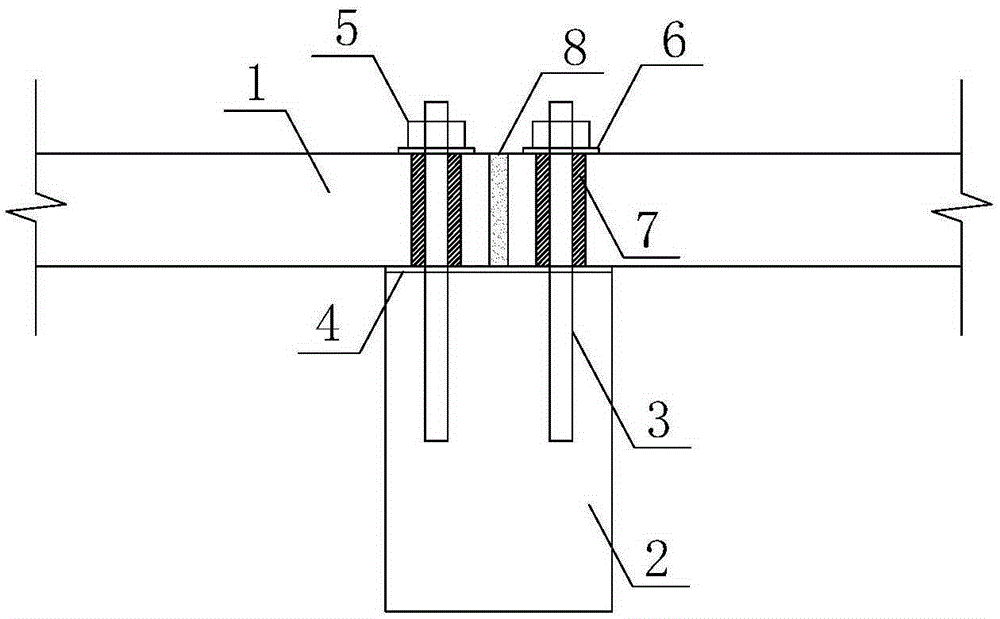

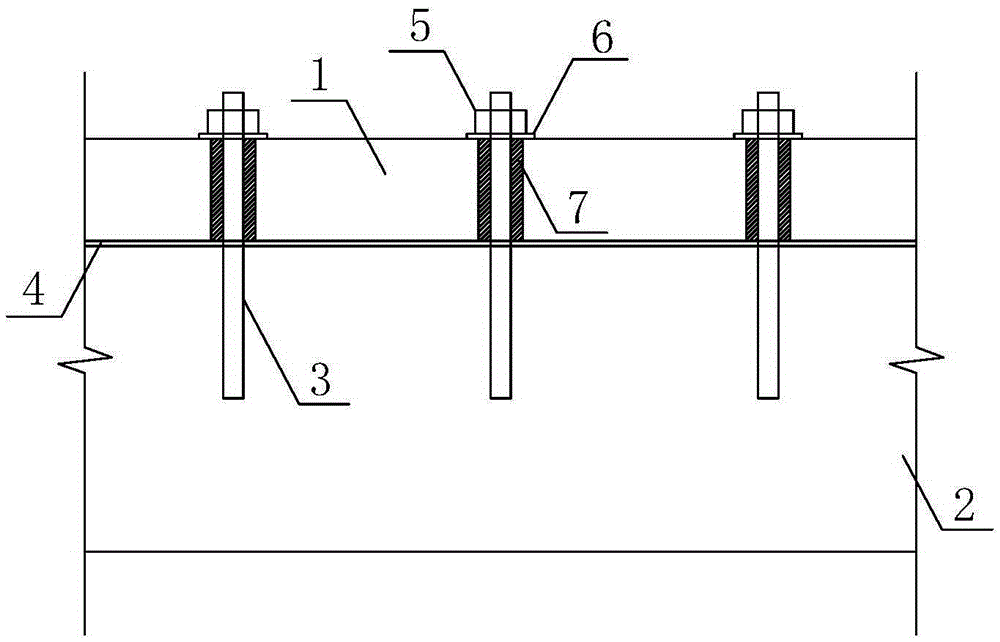

[0018] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

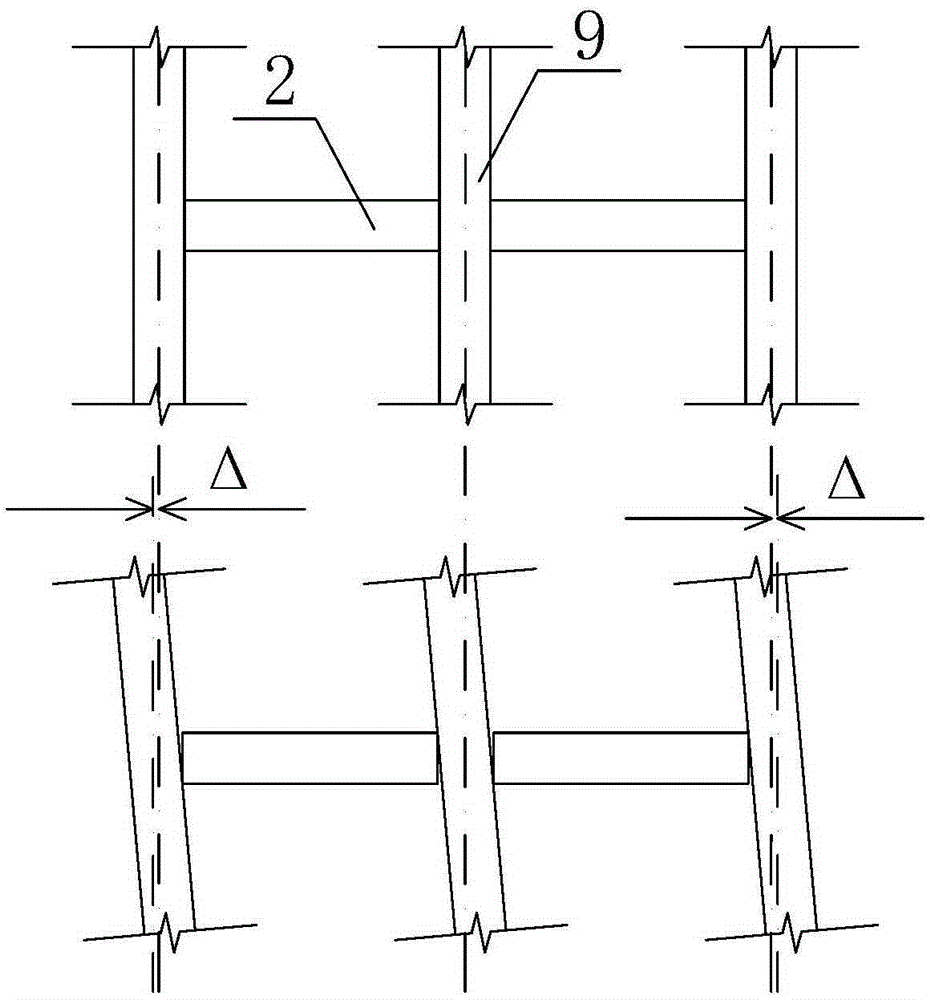

[0019] The invention adopts a beam-slab connection structure applied in a self-resetting structure. The method satisfies the sliding requirement between the slab and the beam by opening a hole in the slab with a diameter larger than that of the screw, and passes the screw around the screw and between the concrete slabs. The voids are filled with plastic foam or foam to achieve the purpose of not constraining the longitudinal slip; at the same time, this connection method can effectively restrain the bending moment caused by the gravity load on the beam-slab connection.

[0020] In addition, because the slabs and beams are generally prefabricated structures, time and cost can be greatly saved. The structure is simple, the construction is fast, the force is reasonable, and it has good technical and economic benefits.

[0021] Such as figure 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com