Buried pipe stretcher

A technology of tensioner and buried pipe, which is applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc. It can solve problems such as cracks running out of water, affecting the normal use of ground source heat pumps, and labor-intensive problems. To achieve the effect of guaranteeing normal use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

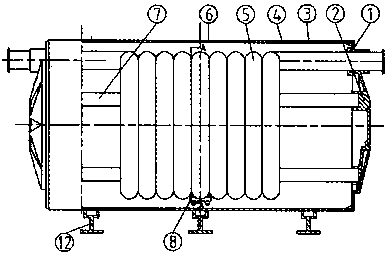

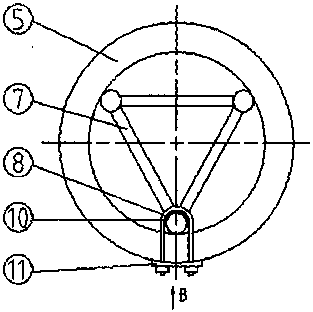

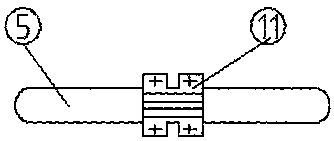

[0025] Embodiment 1: A kind of tensioner for buried pipe, it is set on the support 7 of equilateral triangular light non-metallic material with coil pipe 5 of the same material as the buried pipe, and the center point of the support column of support 7 is respectively set with two U Two U-shaped bolts 8, two U-shaped bolts 8 pass through the gap between the center points of two adjacent coils 5, the fixing plate 11 fixes the two U-shaped bolts 8, and the coiled pipe 5 and the bracket 7 are also fixed; the coiled pipe 5 and the U-shaped There is a rubber pad 10 between the type bolts 8, put the fixed bracket 7 and the coil 5 into the cylinder 4, insert the two ends of the bracket 7 into the pin holes of the end cover 2 at the two ends of the cylinder 4 respectively, and the end cover 2. It is fixed on both ends of the cylinder 4 and fixed by bolts. The two ends of the coil 5 extend out of the cylinder 4 through the holes at both ends of the cylinder respectively. A shaft seal 1 ...

Embodiment 2

[0026] Embodiment 2: A kind of tensioner for buried pipe, which is set on the upper end of the bracket 7 column of equilateral triangular light non-metallic material and the coil pipe 5 of the same material as the buried pipe, and the inner wall of U-shaped bolt 8 is welded and fixed Steel strip 9, the upper end of coil 5 is set with U-shaped bolt 8, the upper end of support 7 column has a hole, U-shaped bolt 8 is inserted into the hole of support 7 column, and fixed with coil 5, between coil 5 and steel strip 9 There is a rubber pad 10, the fixed bracket 7 and the coil 5 are placed in the cylinder 4, the end cover 2 is respectively fixed on both ends of the cylinder 4, and the two ends of the bracket 7 are respectively inserted into the pin holes in the end cover 2 , the two ends of the coil 5 protrude through the holes at both ends of the cylinder 4 respectively, and a sealing shaft 1 is provided between the coil 5 and the end cover to prevent sand or water from entering the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com