Cap printing and embroidering pattern covering process

A hat cover and pattern technology, applied in embroidery machines, embroidery machine mechanisms, textiles and papermaking, etc., can solve the problems of printing paste carry-out and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

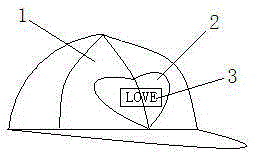

[0012] Such as figure 1 As shown, the hat body is made of multiple pieces of cloth 1 stitched together, and the printed pattern 2 and embroidery pattern 3 in the front straddle the two pieces of cloth, and the printed pattern 2 is printed on the cloth before the stitching of the cloth 1 Yes, because the hat has a certain curvature, in order not to deform the pattern after seaming, the printed pattern needs to be deformed in pieces, and the embroidery pattern 3 is embroidered as a whole after the stitching of the cloth pieces is completed.

[0013] The process of printing and embroidery patterns for hat sleeves according to the present invention comprises the following steps:

[0014] (1) Divide the printed pattern into two halves according to the stitching line of the cloth pieces, and deform them respectively through computer image processing software. The inner deformation of the printed pattern stitching matches the radian of the cloth pieces;

[0015] (2) The deformed pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com