A Linked Space Repeated Locking and Release Mechanism

A technology of repeated locking and releasing mechanism, applied in the aerospace field, can solve problems such as poor reliability and controllability, and achieve the effects of reliable locking and tightening, small impact and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

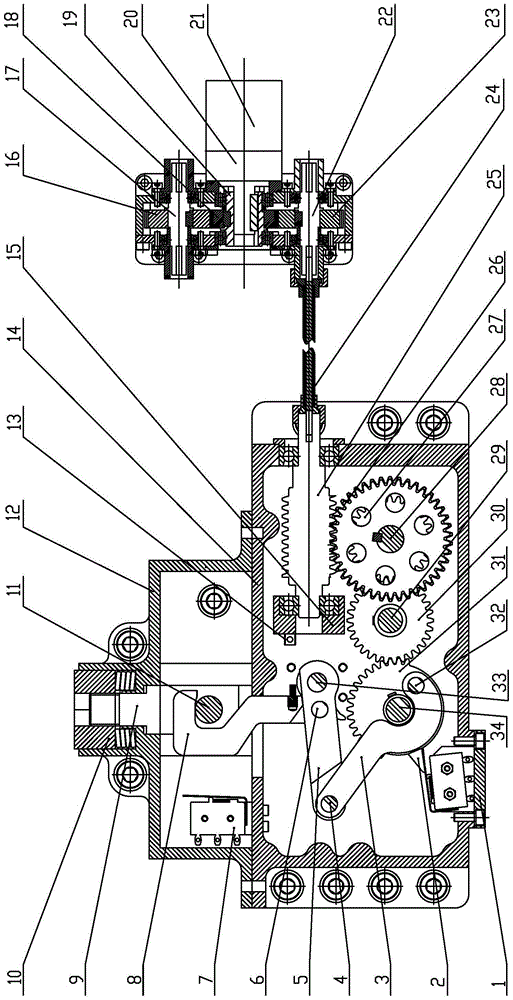

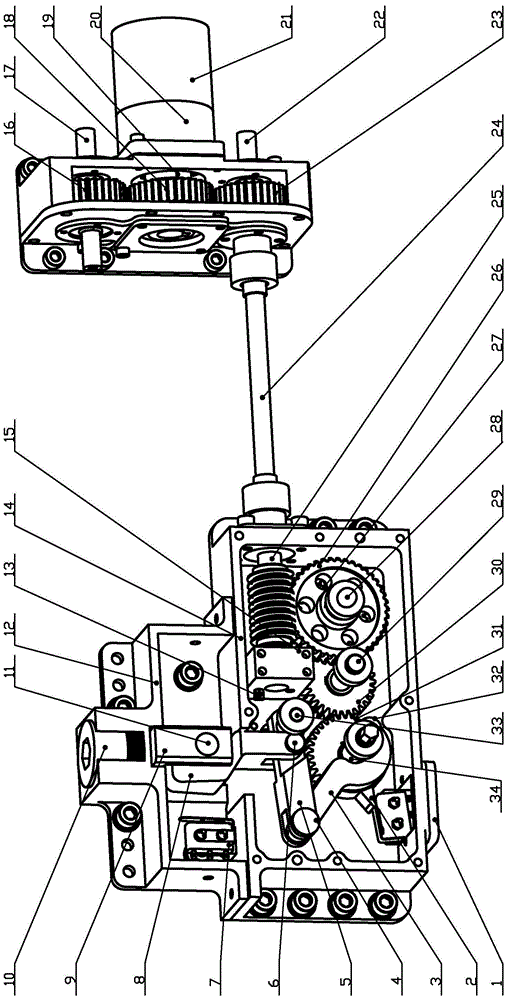

[0014] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment. The interlocking space repetitive locking and releasing mechanism described in this embodiment includes a repeatable locking and releasing mechanism and a linkage driving mechanism. The repeatable locking and releasing mechanism includes a locking mechanism and a locked component. The locking mechanism includes a connecting rod 3, a rocker connecting rod shaft 4, a rocking rod 5, a lock hook rocker shaft 6, a lock hook 8, a locking housing 14, a bearing base 15, a worm 25, a worm wheel 26, a first Transition gear 27, first transition gear shaft 28, second transition gear shaft 29, second transition gear 30, crank gear 31, crank connecting rod shaft 32, rocker shaft 33 and crank gear shaft 34, bearing base 15 is installed in the lock In the tight housing 14, one end of the worm 25 is inserted on the bearing base 15, the other end of the worm 25 passes through the side wall of the ...

specific Embodiment approach 2

[0016] Specific implementation mode two: combination figure 1 and figure 2 Describe this embodiment, the locked mechanism of a linkage type space repeated locking release mechanism described in this embodiment includes a loading rod 9, a loading nut 10, a locked shaft 11 and a locked housing 12, the loading rod 9 Inserted in the locked housing 12, the upper end of the loading rod 9 is connected with the loading nut 10, the lower end of the loading rod 9 is connected with the locked shaft 11, and the locked shaft 11 is articulated with the mouth of the locking hook 8.

[0017] The technical effect of this embodiment is: with such an arrangement, by turning the loading nut 10 , the loading rod 9 can be moved up and down in a straight line, and then the position of the locked shaft 11 can be adjusted. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0018] Specific implementation mode three: combination figure 1 and figure 2 Describe this embodiment, the locking mechanism of a linkage type space repetition locking release mechanism described in this embodiment also includes a corner block 1, a single-tooth crank 2 and a micro switch 7, one end of the single-tooth crank 2 and the crank gear 31 Connect, the other end of the single-tooth crank 2 is in contact with the microswitch 7 installed at the installation port on the side wall of the locking housing 14, and the corner block 1 is installed at the installation port on the side wall of the locking housing 14.

[0019] The technical effect of this embodiment is: so set, the micro switch 7 is in contact with the single-tooth crank 2 on the crank gear 22 in the locked state to release the signal to turn off the motor. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com