Manual bomb vehicle

A technology for a trailer and car body, which is applied to aircraft parts, ground devices, transportation and packaging, etc., can solve the problems of high design and use costs, prone to failures, and many operators, and achieves low design and use costs. The effect of high working reliability and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

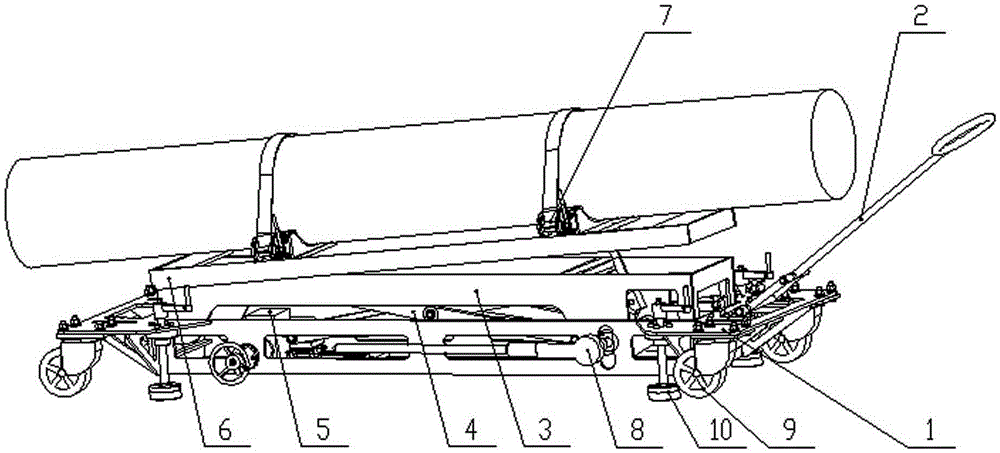

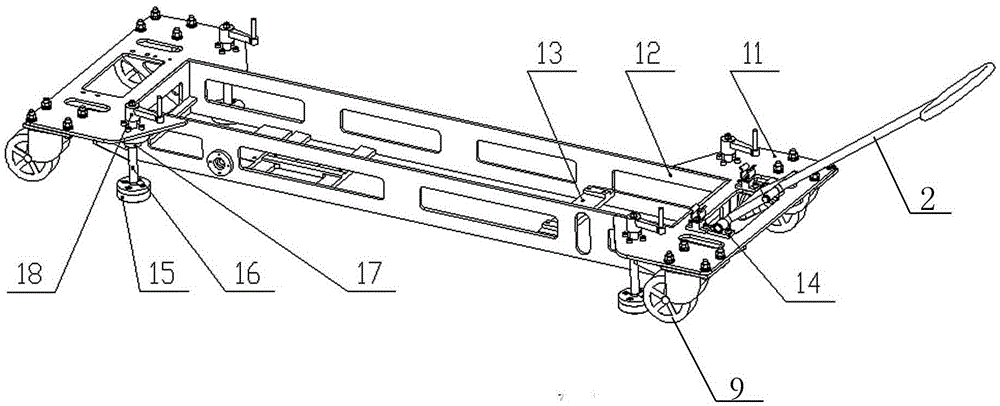

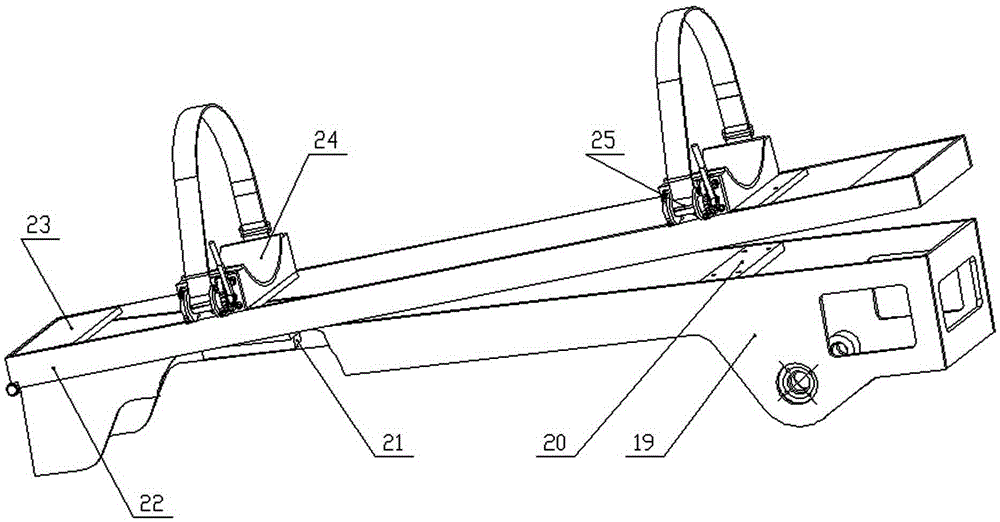

[0016] Below in conjunction with accompanying drawing, this hand-loaded bomb vehicle is further described.

[0017] Such as figure 1 , the manual bomb-loading vehicle includes a vehicle body 1 and a traction handle 2 hinged at the end of the vehicle body 1. The middle part of the vehicle body 1 is arranged in the shape of a rectangular groove, and an inner box is arranged in the groove 3 and scissors mechanism 4; the front lower end of said scissors mechanism 4 is hingedly connected with said car body 1, and the rear lower end of said scissors mechanism 4 is assembled with a manual reducer screw drive mechanism 5, said scissors The front upper end of the fork mechanism 4 is hingedly connected with the inner box body 3, and the rear upper end of the scissor mechanism 4 is slidingly fitted with the inner box body 3; Body bracket 6, the rear end of the body bracket 6 is hinged to the upper rear end of the inner box 3, and the body bracket 6 is provided with a body fixing device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com