Grinding device

A technology for grinding and processing objects, used in grinding/polishing equipment, parts of grinding machine tools, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Hereinafter, modes (embodiments) for carrying out the present invention will be described in detail with reference to the drawings. The present invention is not limited to what is described in the following embodiments. In addition, the constituent elements described below include those easily conceivable by those skilled in the art and those substantially the same. Furthermore, the configurations described below may be appropriately combined. In addition, various omissions, substitutions, or changes in the structure can be made without departing from the gist of the present invention.

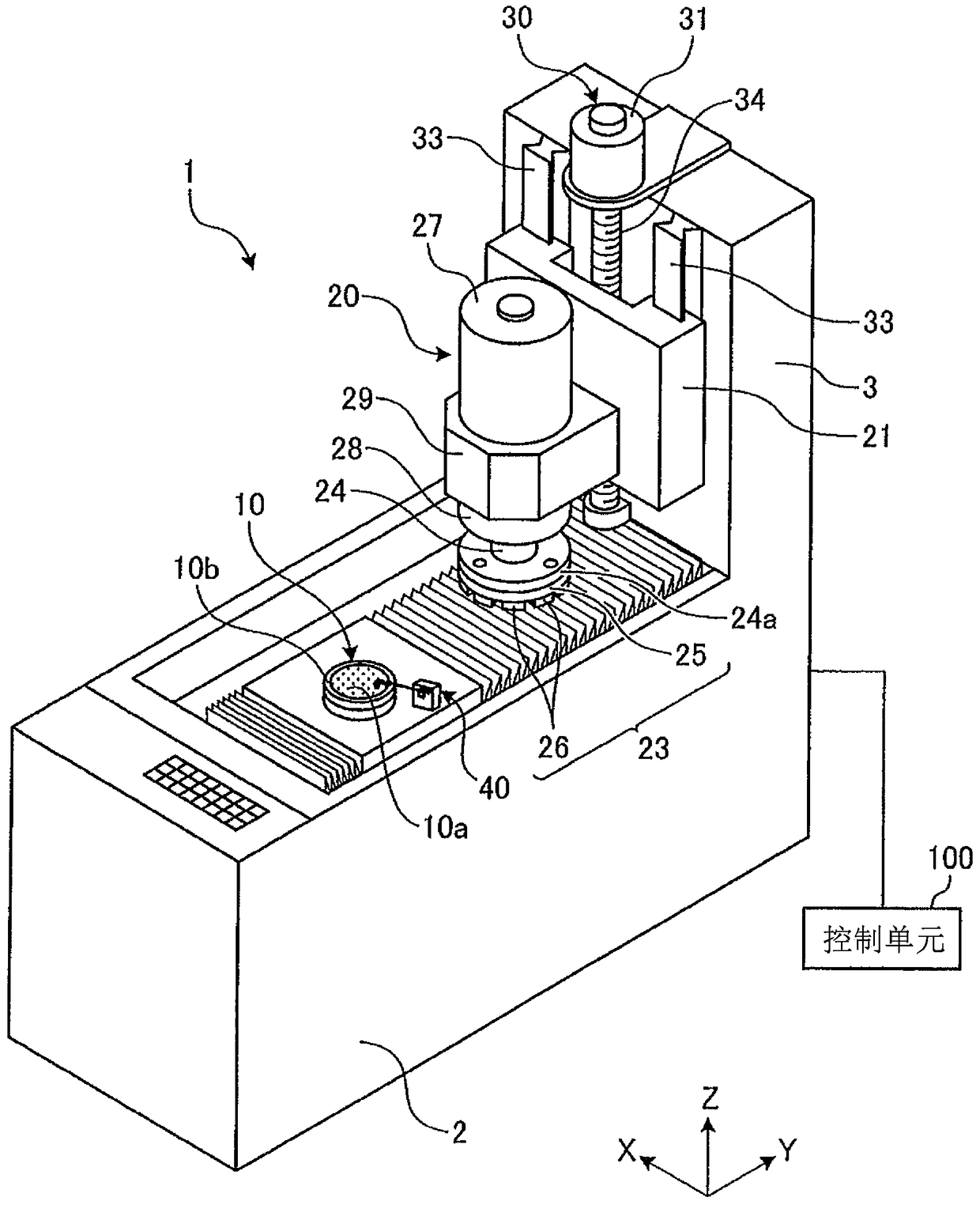

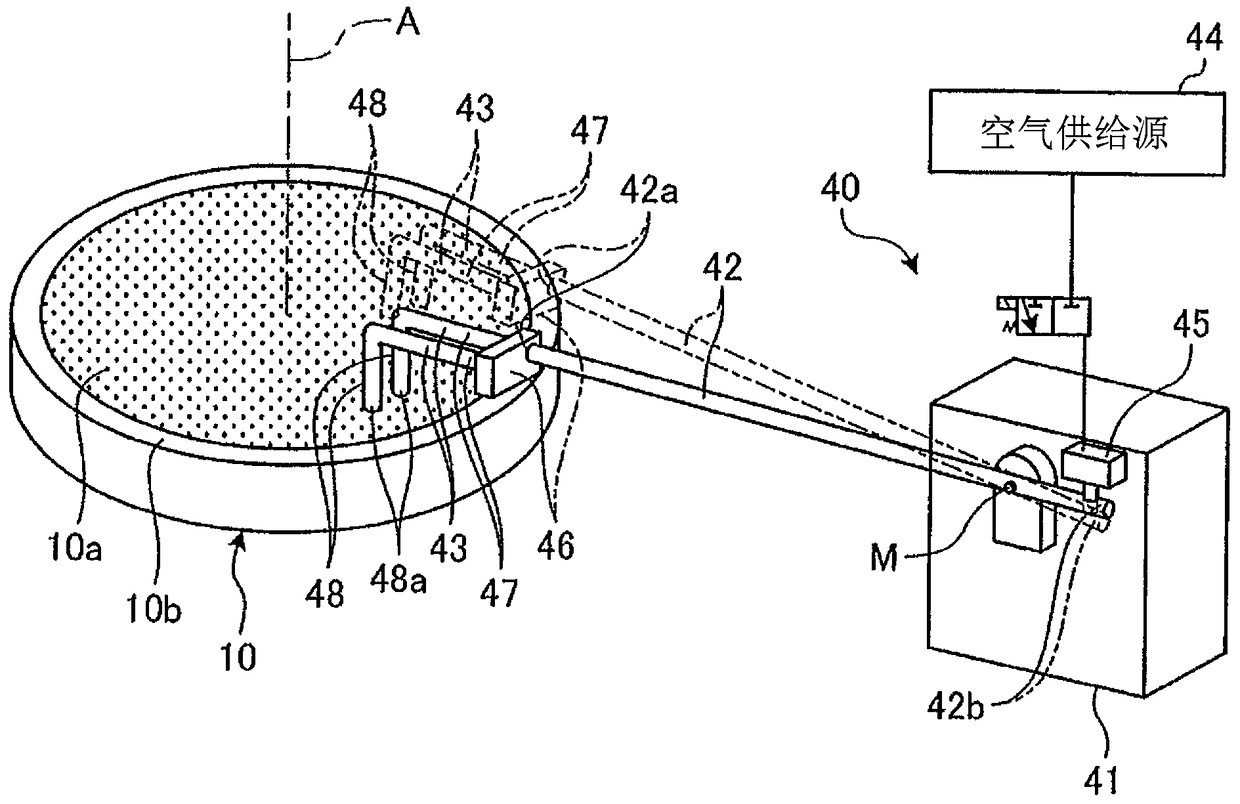

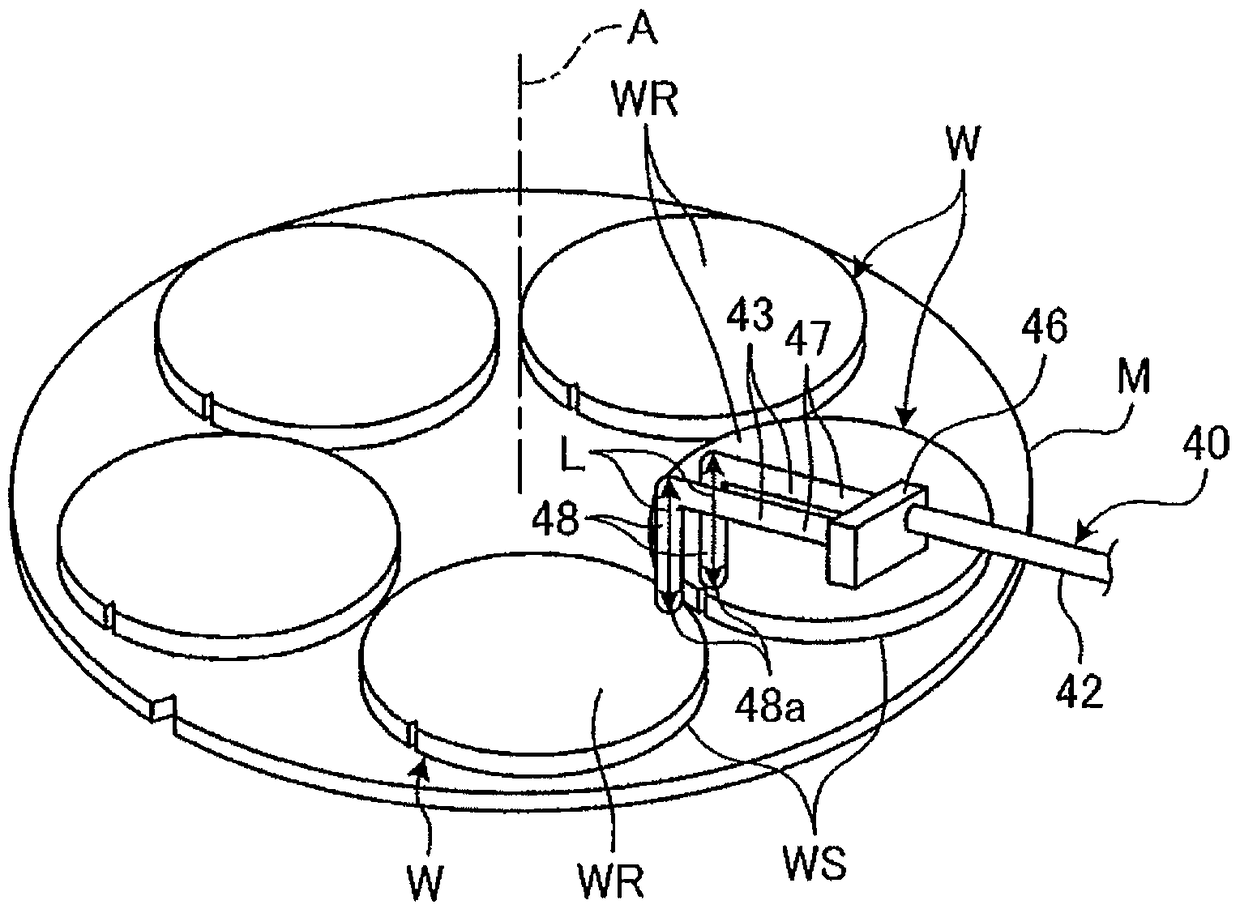

[0018] according to Figure 1 to Figure 5 A grinding device according to an embodiment of the present invention will be described. figure 1 It is an external perspective view showing the structure of the grinding device of the embodiment, figure 2 It is a perspective view of the holding unit, the height measuring device, etc. of the grinding device of the embodiment, image 3 It i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com