Automatic chopstick forming machine with rotating device

A technology of automatic molding machine and rotating device, which is applied in the direction of grinding drive device, abrasive belt grinder, grinding machine tool parts, etc., can solve the problems of low production efficiency, time-consuming and laborious, etc., achieve high production efficiency, reduce power components, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

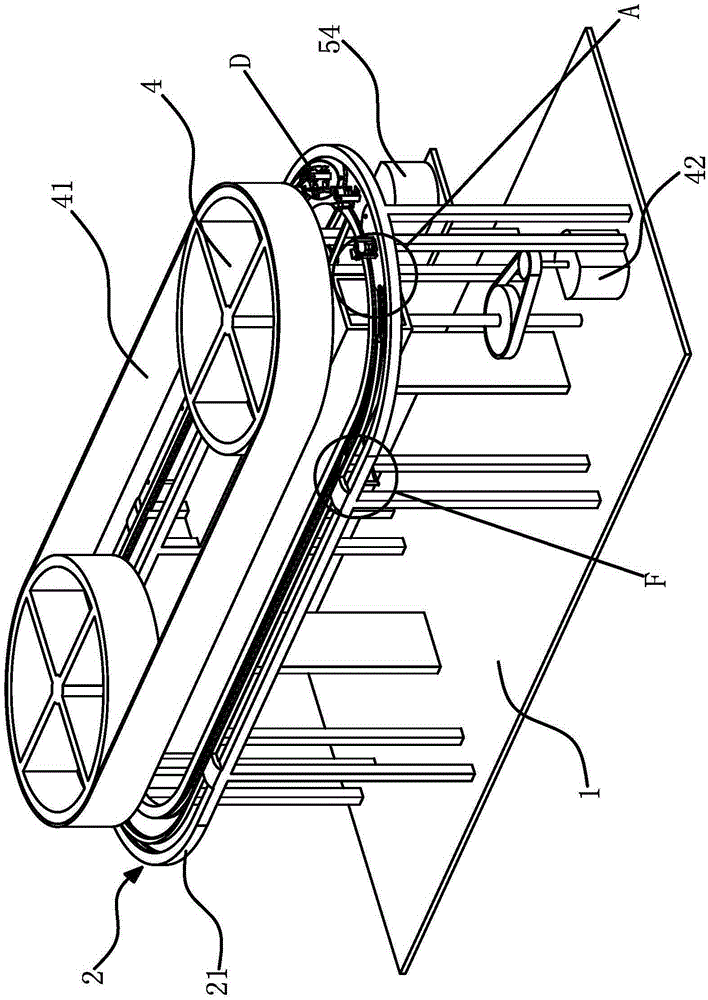

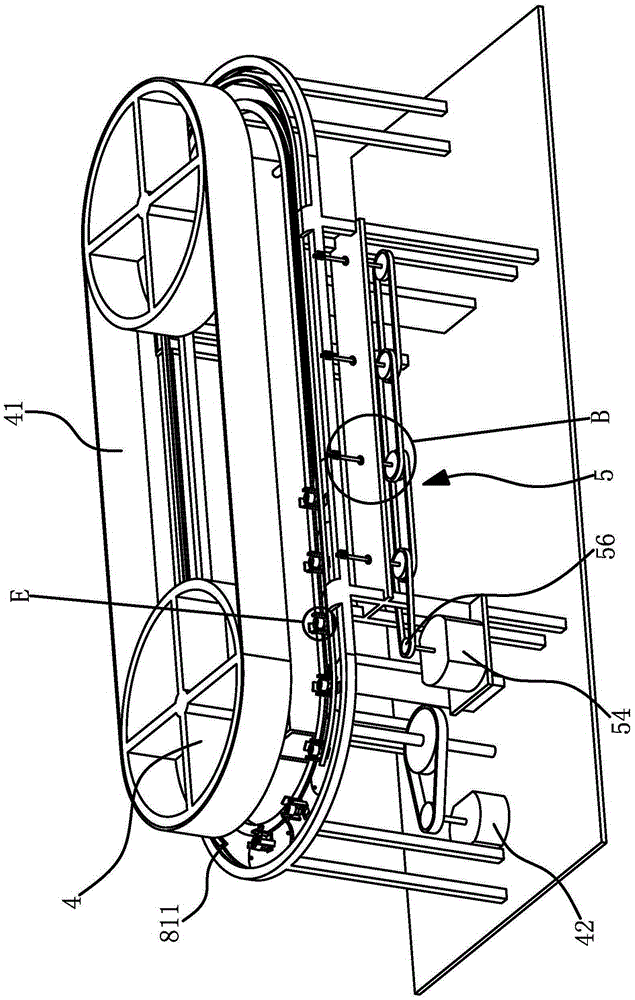

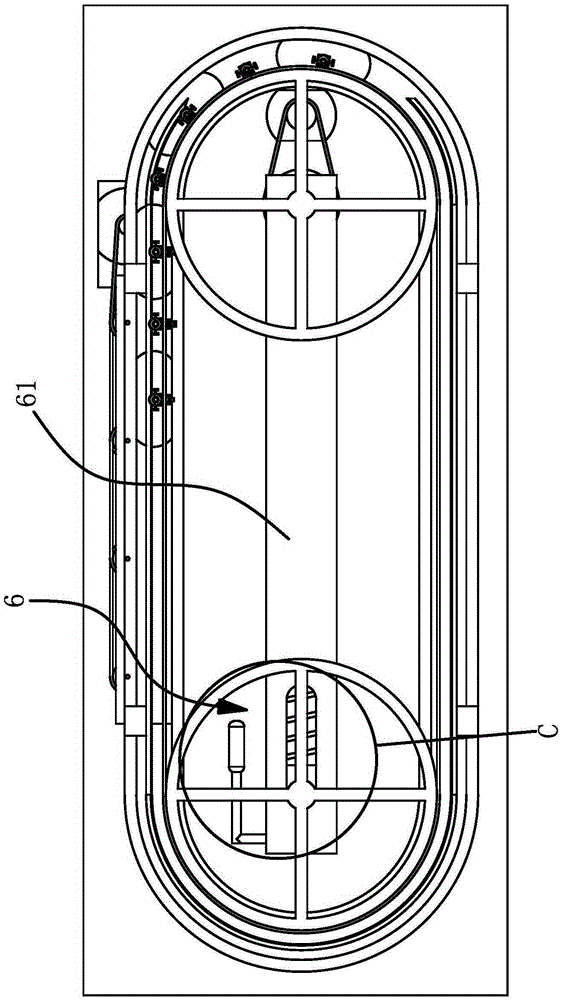

[0035] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 9 , Figure 10 As shown, an automatic chopstick forming machine with a rotating device includes a base plate 1. The base plate 1 is placed stably on the ground. An annular guide rail 2 is horizontally erected on the base plate 1. The lower side of the guide rail 2 is horizontally erected on There is a certain height between the base plate 1 and the base plate 1, which is convenient for staff to operate. A plurality of support plates 3 are slidably connected to the guide rail 2, and the support plates 3 are all arranged horizontally, and each adjacent two support plates 3 are connected by a pin shaft 31 for rotation, so that they can rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com