Feeding device

A technology of feeding device and feeding trolley, which is applied to the attachment device of sawing machine, metal processing, metal sawing equipment and other directions, can solve the problems of increased cost, high failure rate of feeding device, not economical and practical, etc., and achieves low cost and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

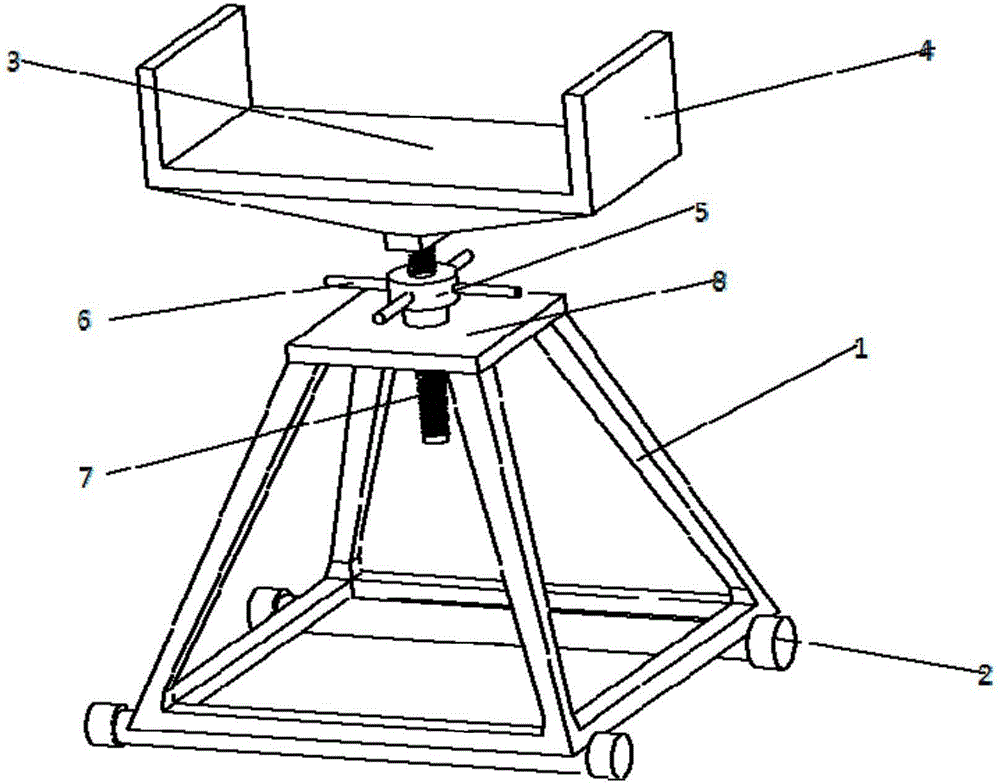

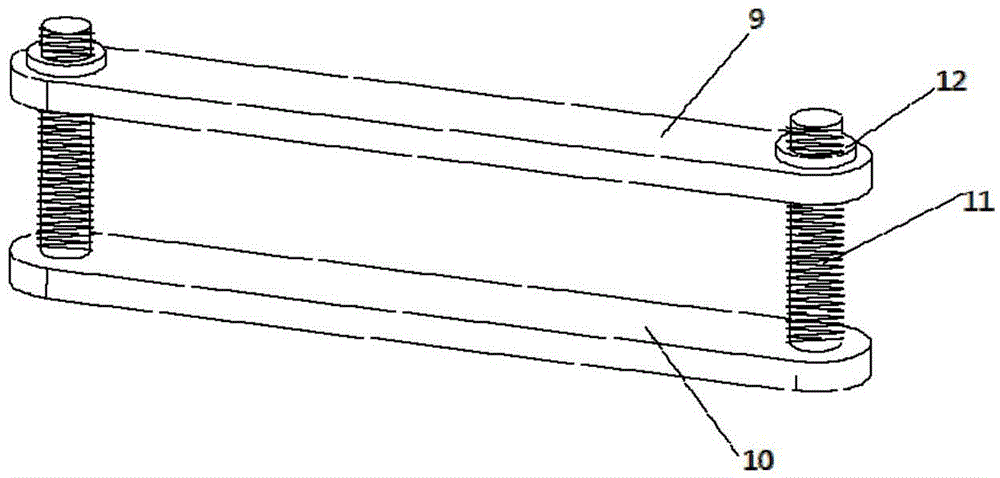

[0013] As shown in the figure, a feeding device includes a feeding trolley and a lock frame. The trolley includes a frame 1 and a tray 3. The frame 1 includes a top plate 8, a screw 7 and a screw nut 5. The top plate 8 has a hole, and the screw nut 5 The bearing is fixed on the position of the hole on the upper surface of the top plate 8, the screw nut 5 is coaxial with the hole, the screw nut 5 is sleeved on the lead screw 7, and the lower end of the lead screw 7 extends out of the lower surface of the top plate 8 through the hole, and the screw nut 5 The upper end of bar 7 is fixed with the bottom of tray 3. The nut 5 has a plurality of handles 6 evenly distributed around its axis.

[0014] There are rollers 2 at the bottom of the vehicle frame 1 . Both sides of the tray 3 have side baffles 4 . The workpiece is mounted on the pallet 3, and one end of the workpiece is mounted on the head of the band sawing machine. Turn the handle 6 to move the lead screw 7 up and down to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com