Rough Machining Method of Turbine Blade Damping Boss

A technology of turbine blades and bosses, which is applied in the field of rough machining of turbine blade damping bosses, can solve problems such as high tool consumption, low processing efficiency, and blade deformation, and achieve improved processing quality, improved processing efficiency, and uniform margin Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to describe the technical features and functions of the present invention in detail and realize them according to the content of this specification, the implementation of the present invention will be further described below in conjunction with the accompanying drawings.

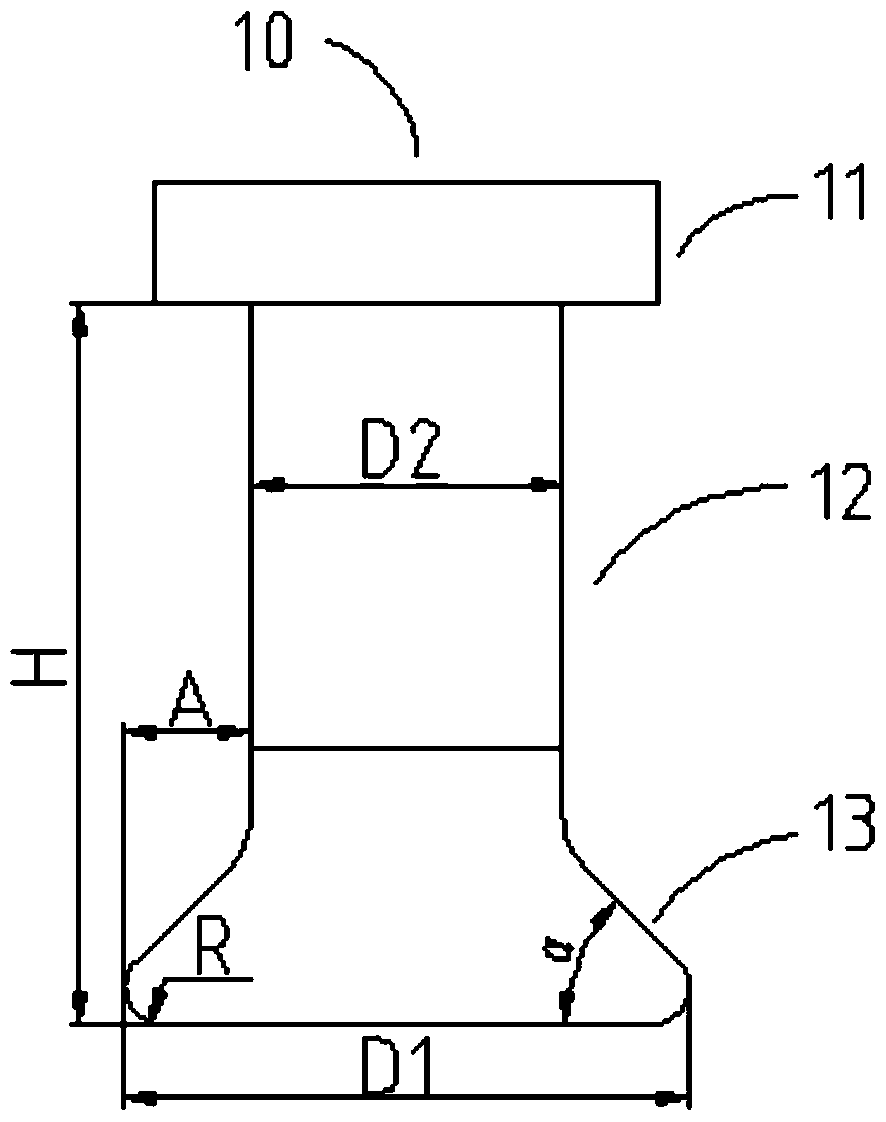

[0027] figure 1 An embodiment of a tool 10 according to the invention is schematically shown. Such as figure 1 As shown, the tool 10 includes a tool handle 11 , a tool bar 12 and a tool head 13 . Among them, H is the overhang length of the tool, which should be greater than the maximum distance from the top of the damping boss to the steam channel profile, D1 is the maximum working diameter of the cutting edge, D2 is the diameter of the tool bar 12, and the tip R is determined by the blade. The selection principle It is advisable not to be larger than the rounded corner of the blade processing part. The A value is the radius difference between the cutter head 13 and the cutter bar 12. When ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com