Copper sleeve centrifugal casting device

A centrifugal casting and copper sleeve technology, applied in the field of copper sleeve production, can solve the problems of uneven density of copper sleeves, unfavorable mass production, low production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below by means of specific embodiments:

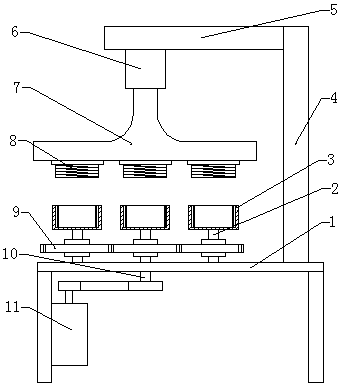

[0011] The reference numerals in the accompanying drawings include: frame 1, transmission shaft 2, mold 3, pillar 4, cantilever 5, cylinder 6, mold cover 7, resistance ring 8, gear 9, drive shaft 10, motor 11.

[0012] The embodiment is basically as attached figure 1 Shown: a copper sleeve centrifugal casting device, including a frame 1, a motor 11, a cylinder 6, a mold 3 and a mold cover 7. The upper right side of the frame 1 is fixed with a vertical pillar 4 , the top of the pillar 4 is fixed with a horizontal cantilever 5 , and the cylinder 6 is fixed at the free end of the cantilever 5 . The mold cover 7 is a circular silicon nitride ceramic piece, and the mold cover 7 is fixed on the output end of the cylinder 6. The lower end of the mold cover 7 is provided with several resistance coils 8 formed by spirally winding filamentary Cr20Ni80. The interior of the pillar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com