Device for straightening steel wire split from steel wire rope

A steel wire rope and straightening technology, which is applied in the field of steel wire rope splitting and steel wire straightening devices, can solve the problems of steel wire surface deformation, inaccurate results, and straightening, etc., and achieve the effect of adjustable running speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

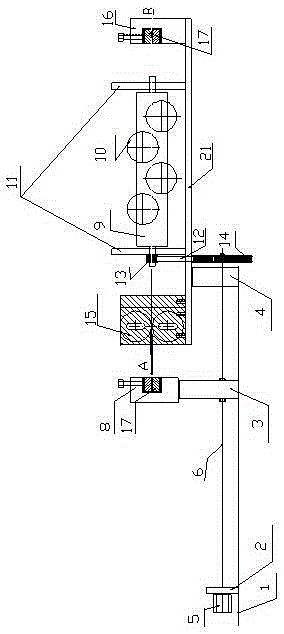

[0010] The present invention will be further described below in conjunction with accompanying drawing:

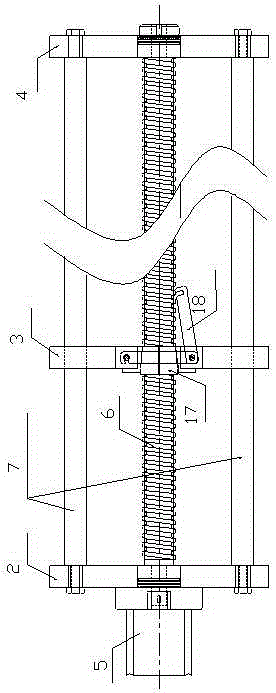

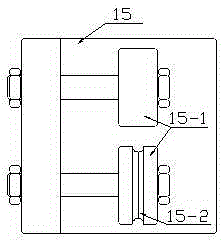

[0011] refer to figure 1 and figure 2 , a chassis 1, a first support 2, a second support 3, a third support 4, a stepping motor 5, a ball screw 6, two guide rails 7, a clamping mechanism 8, an adjusting Straight wheel frame 9, four straightening wheels 10, support frame 11, synchronous belt 12, the first synchronous belt pulley 13, the second synchronous belt pulley 14, feed total journey 15, pretension mechanism 16 and tray 21; Wherein, the first The first support 2 and the third support 4 are respectively fixed on the chassis 1, the two ends of the two guide rails 7 are respectively fixed on the first support 2 and the third support 4, the middle part of the second support 3 is connected with the ball screw 6 is connected and fixed, the two ends of the second support 3 are placed on the two guide rails 7 respectively, and slide on the two guide rails 7 through the chut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com