Dry quenching primary dust collector structure and dedusting method thereof

A dust collector and coke dry quenching technology, applied in the field of coke dry quenching, can solve the problems of easy deformation, low reliability, easy brick falling off, etc., and achieve the effect of improving the overall strength, prolonging the service life and saving maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below with reference to the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

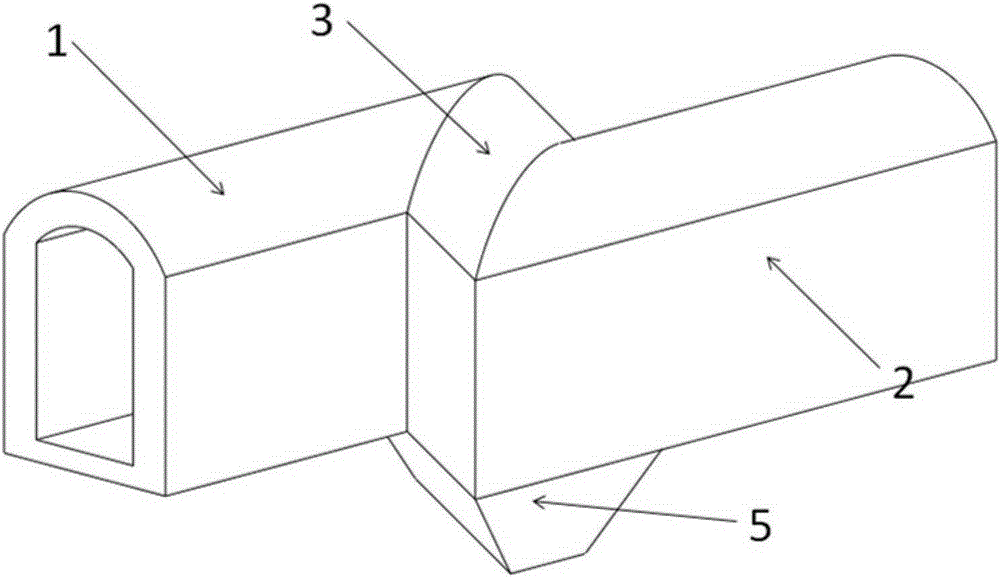

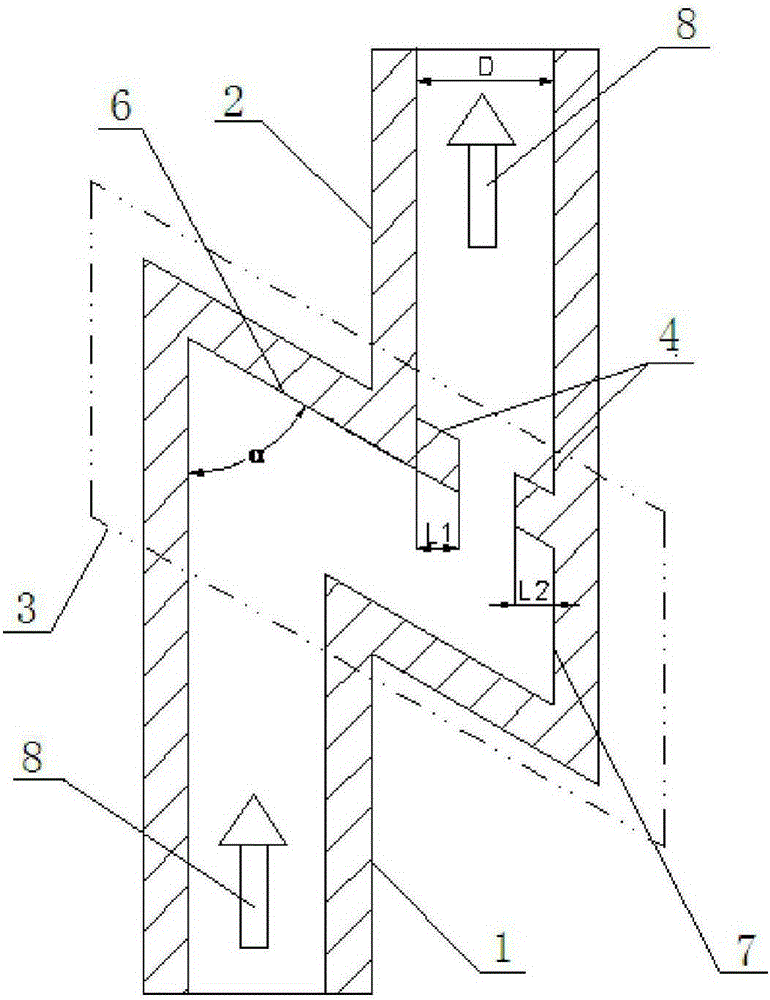

[0015] like Figure 1-Figure 2 As shown, a CDQ primary dust collector structure includes a dust collector inlet 1, a dust collector outlet 2, a dust removal channel and an ash hopper 5 arranged at the bottom of the dust removal channel; at least one Z-shaped channel is arranged on the dust removal channel Structure 3, two dust removal retaining walls 4 are laterally arranged at the corners of the zigzag channel structure 3, the two dust removal retaining walls 4 are arranged oppositely, and an airflow channel is formed between the retaining walls, and the ash hopper 5 is arranged in a zigzag shape. Bottom of channel structure 3.

[0016] The folding angle α of the zigzag channel structure: 45°≤α≤90°.

[0017] The sum of the lengths L1 and L2 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com