Oxidized graphene-metallic fullerene compound, method for preparing same and application of oxidized graphene-metallic fullerene compound

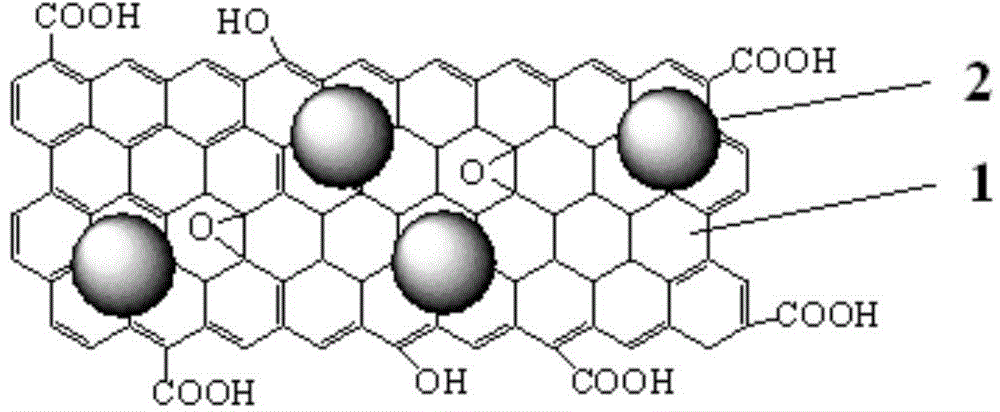

A metallofullerene and composite technology, applied in the field of nanomaterials, can solve the problems of incomplete carbon cage structure, embedded metal leakage, etc., and achieve the effect of simple method, high relaxivity and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

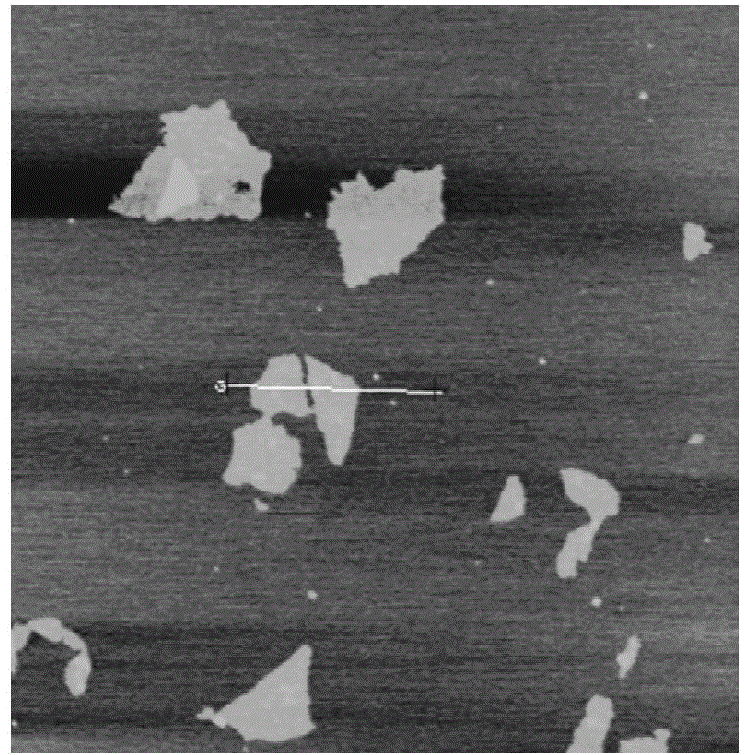

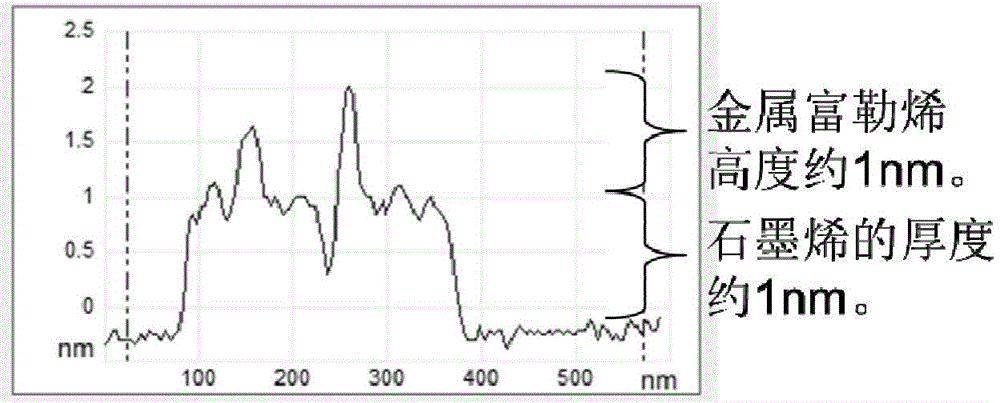

[0033] The preparation of embodiment 1 graphene oxide-metal fullerene compound

[0034] 1. Preparation of graphene oxide

[0035] According to Hummer's method: add graphite (0.25g) to concentrated sulfuric acid (11ml) at 0°C, and gradually add KMnO 4 (0.75g), control temperature is lower than 20 ℃, stir 4h, carry out low-temperature reaction; Be warming up to 35 ℃ afterwards, continue to stir 30 minutes, carry out medium-temperature reaction; Then add ultrapure water (12 milliliters) slowly, carry out high-temperature reaction, Keeping the solution temperature below 100°C, after stirring for 30 minutes, ultrapure water (30 mL) was added. Then, 30% hydrogen peroxide (2 ml) was added to remove unreacted KMnO 4 , the color of the solution turned bright yellow. The obtained product was washed with (150 ml 10 wt%) HCl and deionized water to remove metal ions and SO 4 2- .

[0036] Add the above-prepared product to ultrapure water, disperse by ultrasonic, ultrasonic for 100 mi...

Embodiment 2

[0046] The preparation of embodiment 2 graphene oxide-metal fullerene compound

[0047] 1. Preparation of graphene oxide

[0048] With embodiment 1.

[0049] 2. Preparation of graphene oxide-metal fullerene composites

[0050] Except that the metallofullerene was replaced by GdC60 in chlorobenzene solution (30 ml, 0.002 mg / mL), the rest of the steps were the same as in Example 1.

[0051] The obtained graphene oxide-metal fullerene composite has good water solubility and stability, good relaxivity, and good MRI enhancement effect.

Embodiment 3

[0052] The preparation of embodiment 3 graphene oxide-metal fullerene compound

[0053] 1. Preparation of graphene oxide

[0054] With embodiment 1.

[0055] 2. Preparation of graphene oxide-metal fullerene composites

[0056] The remaining steps were the same as in Example 1, except that the metallofullerene was replaced by a toluene solution of LaC82 (30 mL, 0.5 mg / mL).

[0057] The obtained graphene oxide-metal fullerene composite has good water solubility and stability, good relaxivity, and good MRI enhancement effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com