Lid component of pressure cooker and pressure cooker with lid component

A pressure cooker and pot cover technology, applied in the field of pressure cooker, can solve the problems of complex sensor manufacturing process, high assembly cost, and low accuracy, and achieve the effects of reducing processing cost and assembly difficulty, simplifying structure and manufacturing process, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

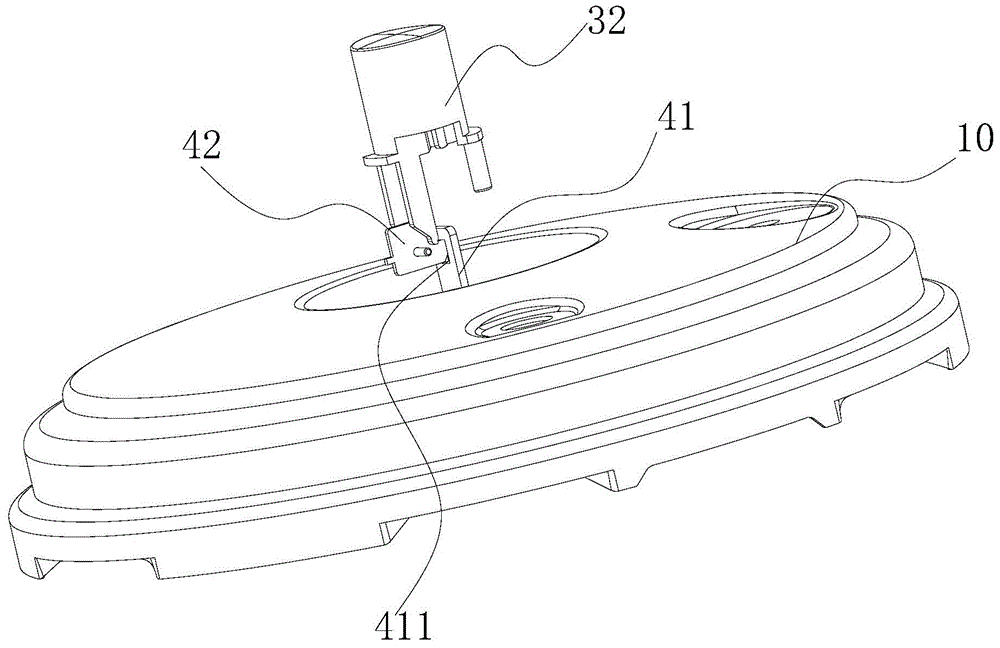

[0051] The preparation material of the buckle device 40 only needs to meet the requirement of being able to connect the pot cover 10 with the pot cover piece 20 . Optionally, the locking tongue 42 and the connecting part 41 of the buckle device 40 can be both plastic parts. Therefore, the locking tongue 42 and the connecting piece 41 made of plastic are easy to form, have a wide range of material sources, and have low manufacturing costs on the premise of satisfying the connection stability between the pot cover 10 and the pot cover connecting piece 20 .

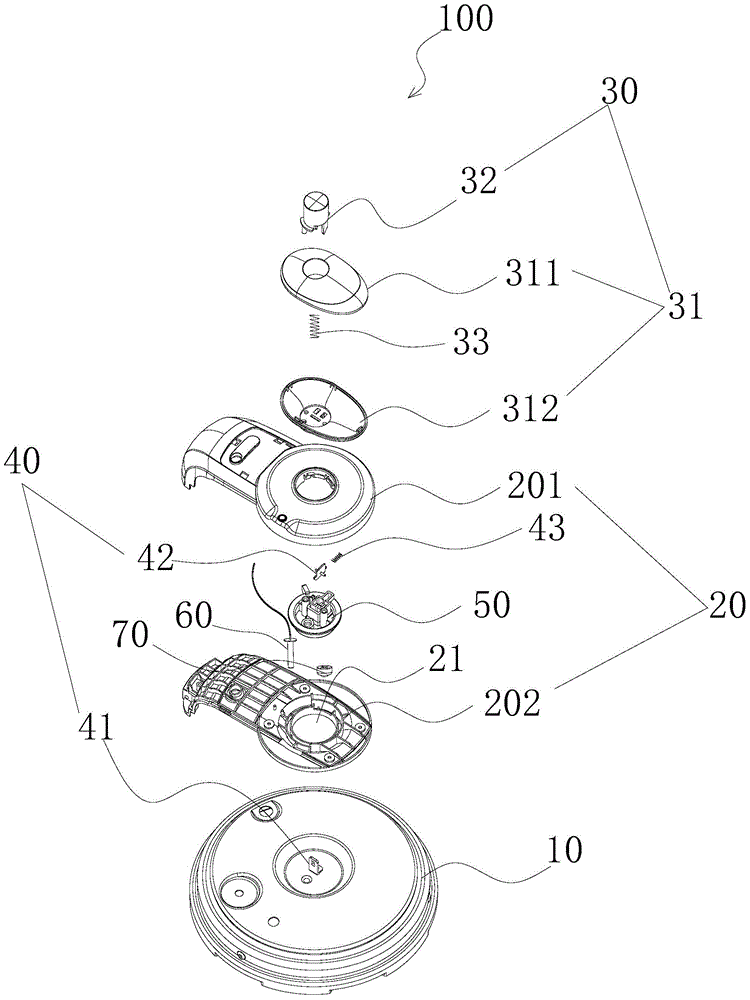

[0052] According to an embodiment of the present invention, the pot cover connecting piece 20 is provided with a mounting part 21, and the pot cover assembly 100 of the pressure cooker also includes a fixing seat 50, and the fixing seat 50 is arranged on the mounting part 21, and the locking tongue 42 is movably set. on the mount 50. Further, the installation part 21 is formed as a through hole passing through the upper surf...

Embodiment 1

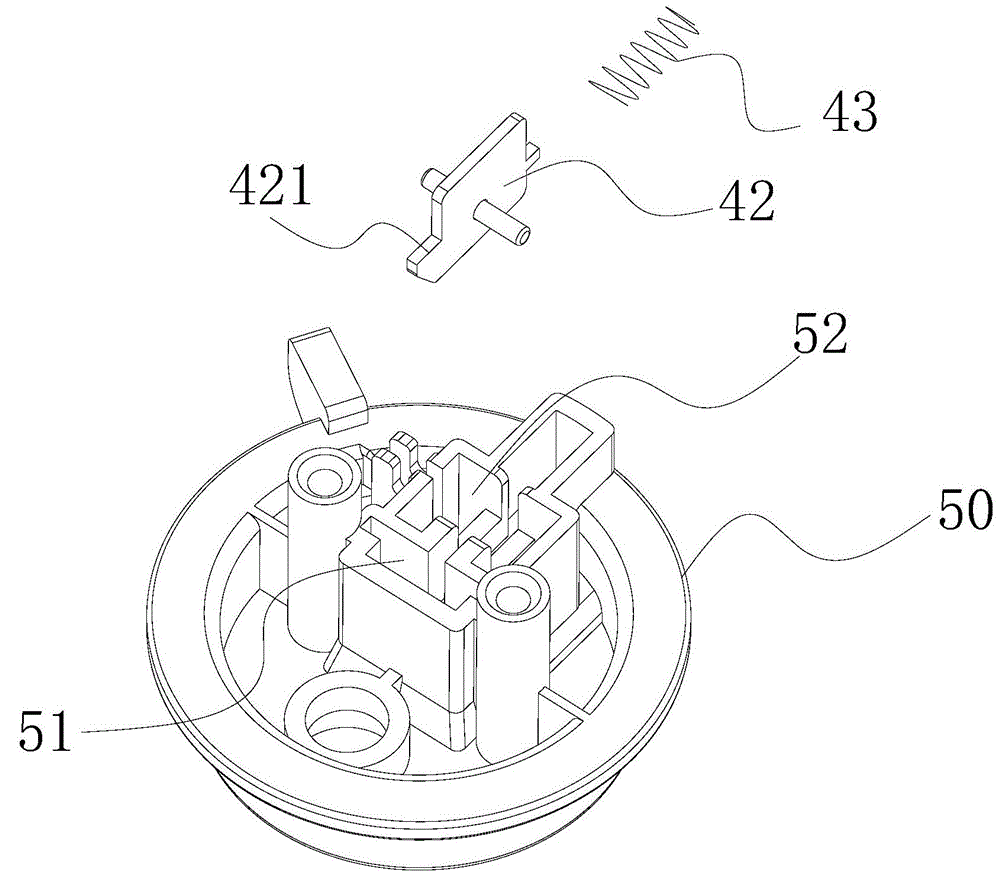

[0063] Such as Figure 4a and Figure 4b As shown, the locking tongue 42 is movably disposed in the receiving groove 52 along the horizontal direction, and the button 32 is movable in the horizontal direction to push the locking tongue 42 to disengage from the connecting member 41 .

[0064] refer to Figure 4a , the accommodating groove 52 is formed as a groove body extending in the left-right direction, and the lock tongue 42 is movably arranged in the escape groove 52 along the left-right direction. Through the fixed seat 50 and into the escape groove 51, the hook 421 of the dead bolt 42 is stuck in the draw-in groove 411 of the connector 41, the dead bolt 42 and the connector 41 cannot be disengaged, and the pot cover 10 is connected with the fixed seat 50 and placed in the Can rotate under the rotation of knob 31.

[0065] When the cover assembly 100 needs to be removed, the Figure 4a The direction indicated by the middle arrow exerts force on the button 32, that is,...

Embodiment 2

[0068] Such as Figure 5a and Figure 5b As shown, the structure of the second embodiment is substantially the same as that of the first embodiment above, wherein the same parts use the same reference numerals, and the difference is that the button 32a and the locking tongue 42a are integrally formed.

[0069] That is to say, the key 32a is a part of the lock tongue 42a, and when an action force is applied to the key 32a, that is, an action force is directly applied to the lock tongue 42a. The use process of the lid assembly 100 of the pressure cooker according to the embodiment of the present invention is similar to the use process of the first embodiment above, so it will not be repeated here.

[0070] According to the embodiment of the present invention, the lock tongue 42a is integrally formed with the button 32a, which not only improves the overall structural stability of the lock tongue 42a and the button 32a, but also facilitates molding and reduces the manufacturing c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com