Electrostatic dust removal facility monitoring terminal

An electrostatic precipitator and monitoring terminal technology, applied in program control, computer control, general control system, etc., can solve the problems of environmental impact, high price, and high operating cost, and achieve low receiving equipment requirements, low cost, and low input cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

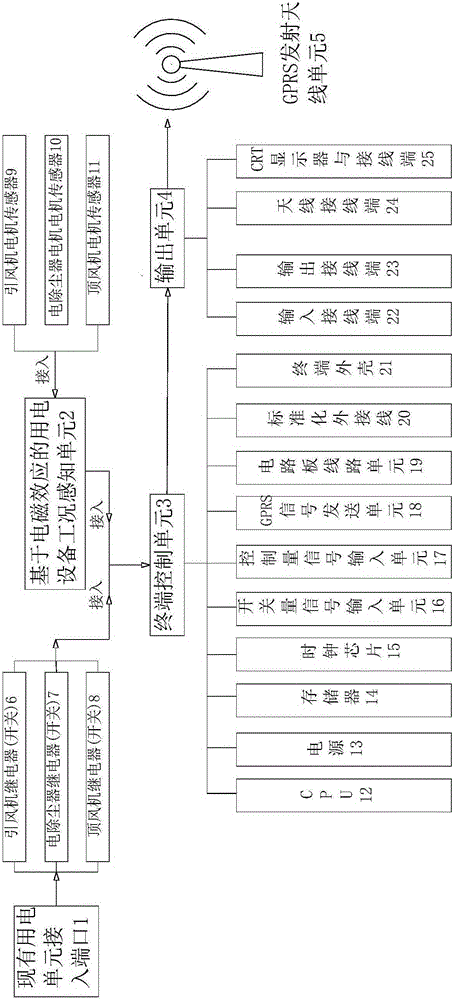

[0015] like figure 1 As shown, the present invention is composed of 5 units including a power unit access port 1, an electromagnetic effect-based power device condition sensing unit 2, a terminal control unit 3, an output unit 4, and a GPRS transmitting antenna unit 5.

[0016] 1. The power consumption unit is connected to port 1, and connected in parallel to the existing bag-type dust removal facility control system (such as a switch cabinet). According to the number of switch units, determine the total number of switch inputs, namely: induced draft fan relay (switch) 6, Electric dust collector relay (switch) 7, top fan relay (switch) 8; By collecting the operating status of these facilities in real time, it is possible to grasp the status of these facilities or equipment on or off. The switch data is directly connected to the switch signal input terminal of the terminal control unit.

[0017] 2. The sensing unit of power consumption condition based on electromagnetic effec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com