Measuring device for perpendicularity and planeness of vertical type rail and measuring method thereof

A measuring device and flatness technology, applied to measuring devices, instruments, etc., can solve the problems of measurement being affected by external factors and not easy to measure, and achieve the effects of low transformation cost, easy transposition work, and improved measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

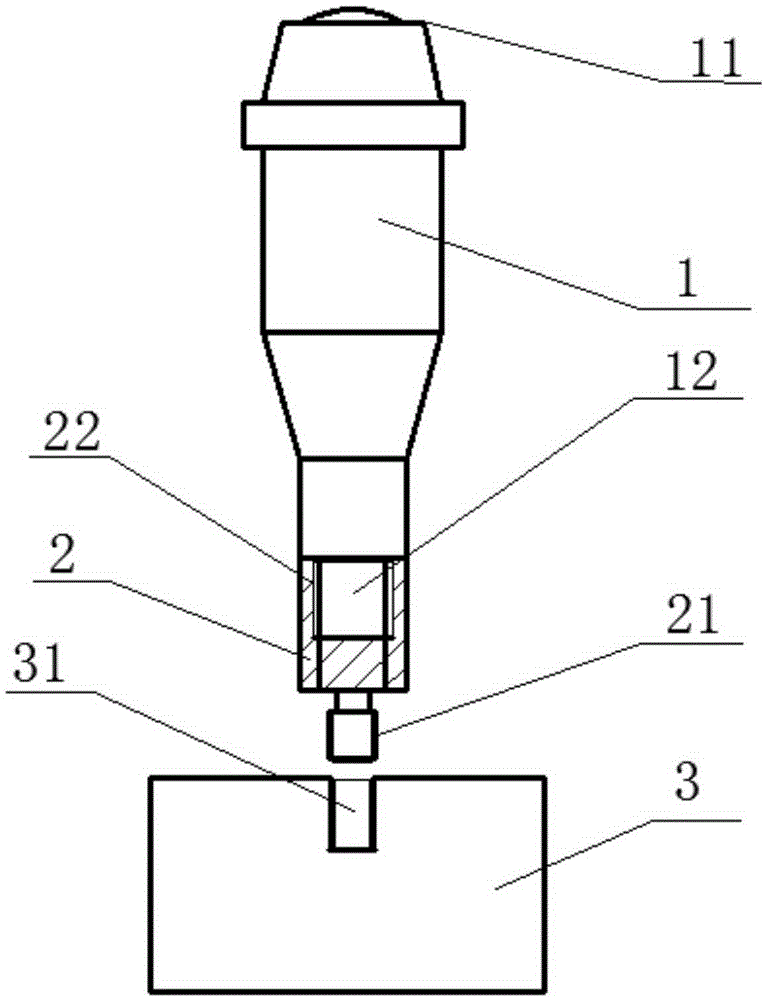

[0041] The measuring device of a kind of vertical track verticality and flatness of this example is applied to the measurement of the verticality of the vertical track, including a measuring unit and a positioning unit, and the measuring unit is a total station; figure 1 As shown, the positioning unit includes a measuring rod 1, a connecting piece 2 and a magnetic base 3; wherein, the measuring measuring rod 1 is fixed on the upper surface of the magnetic base 2 through the connecting piece 2; the flatness of the bottom surface of the magnetic base 2 is less than 0.005mm. Measuring rod 1 is an inner diameter micrometer measuring rod with an accuracy of 0.005mm; the cross section of connecting piece 2 is a T-shaped cylindrical structure, the top end is provided with connecting piece thread groove 22, the lower part is connecting piece threaded rod 21, connecting piece thread groove 22 and measuring The threaded rod 12 at the tail end of the measuring rod 1 is matched and connect...

Embodiment 2

[0060] A kind of perpendicularity measuring device of this example is applied to the perpendicularity of the vertical plane in the narrow space. The basic structure is the same as that of embodiment 1, and the improvement is that: the side of the magnetic base 3 is provided with a magnetic on-off knob 32; and the whole positioning The unit is miniaturized to facilitate positioning in a small space; the measuring unit is the theodolite.

[0061] The measuring method of the measuring device of vertical track verticality and flatness of this example, its step is basic embodiment 1, and difference is: step D, measuring unit selection: the theodolite is placed on its eyepiece and can see inner diameter micrometer amount The position of the measuring rod convex surface 11 of the rod; step H is not required, only the verticality of the vertical plane in the narrow space is detected.

Embodiment 3

[0063] A kind of flatness measuring device of this example is applied to the flatness of the plane in the closed space, and the structure is the same as that of embodiment 2, and the closed space needs to be provided with a visible window (such as a glass window) that can be observed from the outside. The difference is: measurement The unit is a spirit level.

[0064] A vertical rail verticality and flatness measuring device and its measuring method of this example, its steps are basic embodiment 2, the difference is: step D, measuring unit position selection: place the spirit level on its eyepiece to see The position of the measuring rod convex surface 11 of the inner diameter micrometer measuring rod; step H is not required, only the flatness of the plane in the closed space is detected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com