Bracket

A technology of support feet and support rods, applied in the field of brackets, can solve the problems of cumbersome bracket construction, inconvenient storage and carrying, etc., and achieve the effects of protecting property safety, convenient carrying and adjustment, and protecting personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

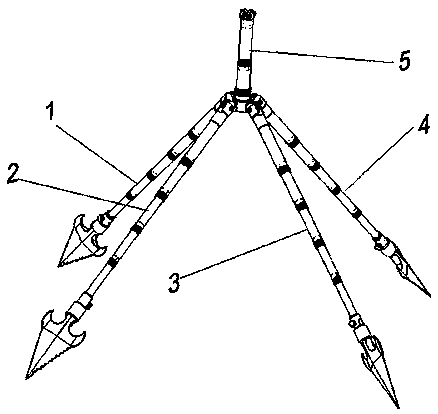

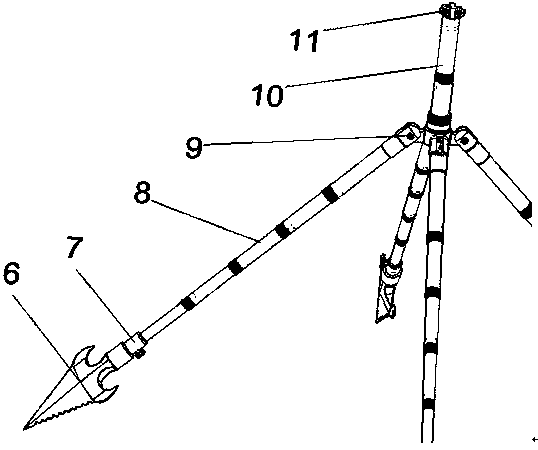

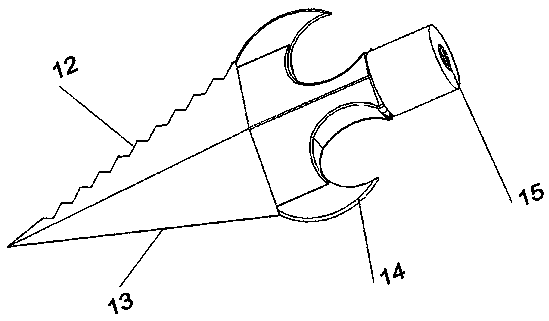

[0056] Embodiment 1: as Figure 1-26 As shown, a bracket includes an adjustable leg 1, an adjustable leg 2, an adjustable leg 3, an adjustable leg 4, and a support rod adjustment and fixing device 5;

[0057] The structure of the adjustable leg one 1, the adjustable leg two 2, the adjustable leg three 3, and the adjustable leg four 4 are all the same and include a leg fixing mechanism 6, a rotary ball valve rotation mechanism 7, a telescopic rod height adjustment mechanism 8, a leg The root adjustment mechanism 9; wherein one end of the leg fixing mechanism 6 is fixed on the ground, the other end of the leg fixing mechanism 6 is screwed tightly to one end of the rotating ball valve rotating mechanism 7, and the other end of the rotating ball valve rotating mechanism 7 is connected to one end of the telescopic rod height adjusting mechanism 8 , the other end of the telescopic rod height adjustment mechanism 8 is connected with one end of the leg root adjustment mechanism 9 .

...

Embodiment 2

[0067] Embodiment 2: as Figure 1-26 As shown, a bracket includes an adjustable leg 1, an adjustable leg 2, an adjustable leg 3, an adjustable leg 4, and a support rod adjustment and fixing device 5;

[0068] The structure of the adjustable leg one 1, the adjustable leg two 2, the adjustable leg three 3, and the adjustable leg four 4 are all the same and include a leg fixing mechanism 6, a rotary ball valve rotation mechanism 7, a telescopic rod height adjustment mechanism 8, a leg Root adjustment mechanism 9; wherein one end of the leg fixing mechanism 6 is fixed on the ground, the other end of the leg fixing mechanism 6 is screwed and connected with one end of the rotary ball valve rotation mechanism 7, and the other end of the rotary ball valve rotation mechanism 7 is connected with one end of the telescopic rod height adjustment mechanism 8 , the other end of the telescopic rod height adjustment mechanism 8 is connected with one end of the leg root adjustment mechanism 9 ....

Embodiment 3

[0076] Embodiment 3: as Figure 1-26 As shown, a bracket includes an adjustable leg 1, an adjustable leg 2, an adjustable leg 3, an adjustable leg 4, and a support rod adjustment and fixing device 5;

[0077] The structure of the adjustable leg one 1, the adjustable leg two 2, the adjustable leg three 3, and the adjustable leg four 4 are all the same and include a leg fixing mechanism 6, a rotary ball valve rotation mechanism 7, a telescopic rod height adjustment mechanism 8, a leg The root adjustment mechanism 9; wherein one end of the leg fixing mechanism 6 is fixed on the ground, the other end of the leg fixing mechanism 6 is screwed tightly to one end of the rotating ball valve rotating mechanism 7, and the other end of the rotating ball valve rotating mechanism 7 is connected to one end of the telescopic rod height adjusting mechanism 8 , the other end of the telescopic rod height adjustment mechanism 8 is connected with one end of the leg root adjustment mechanism 9 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com