Variable capacity mechanism of scroll compressor and scroll compressor

A scroll compressor and compression mechanism technology, applied in the field of scroll compressors, can solve the problems of leakage of working fluid, limitation of the cross-sectional area of the discharge return passage, increase of power consumption of working fluid, etc. Reduce processing difficulty and processing cost, reduce the effect of radial fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The invention will be described in detail below by means of exemplary embodiments with reference to the drawings. The following detailed description of the present invention is for the purpose of illustration only, and in no way limits the present invention and its application or use.

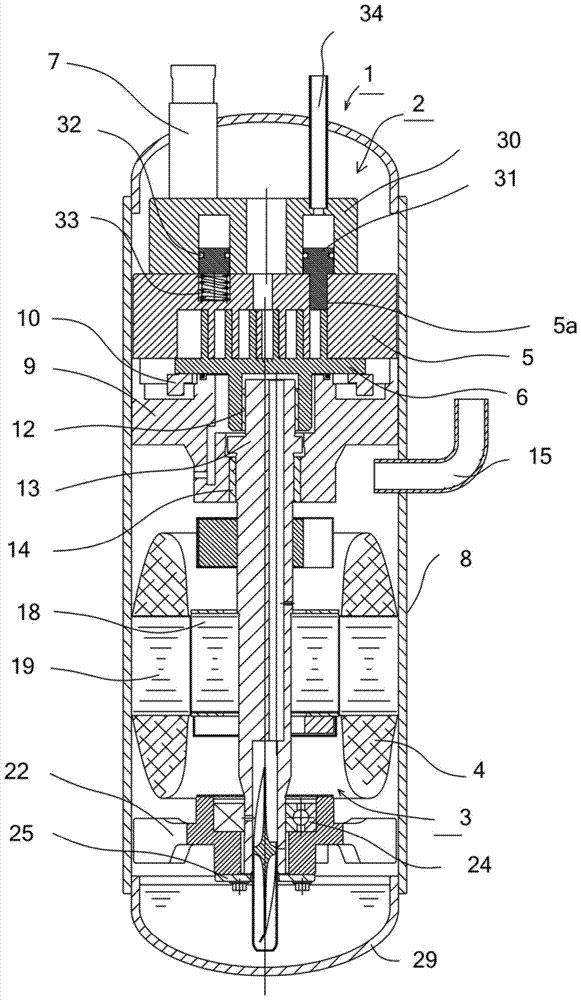

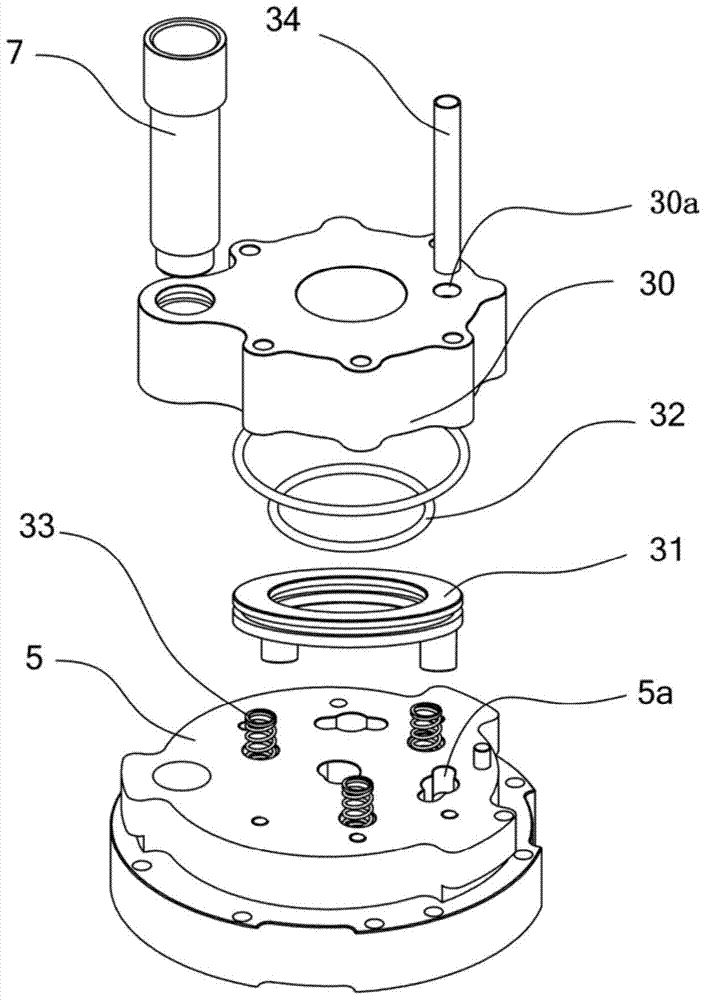

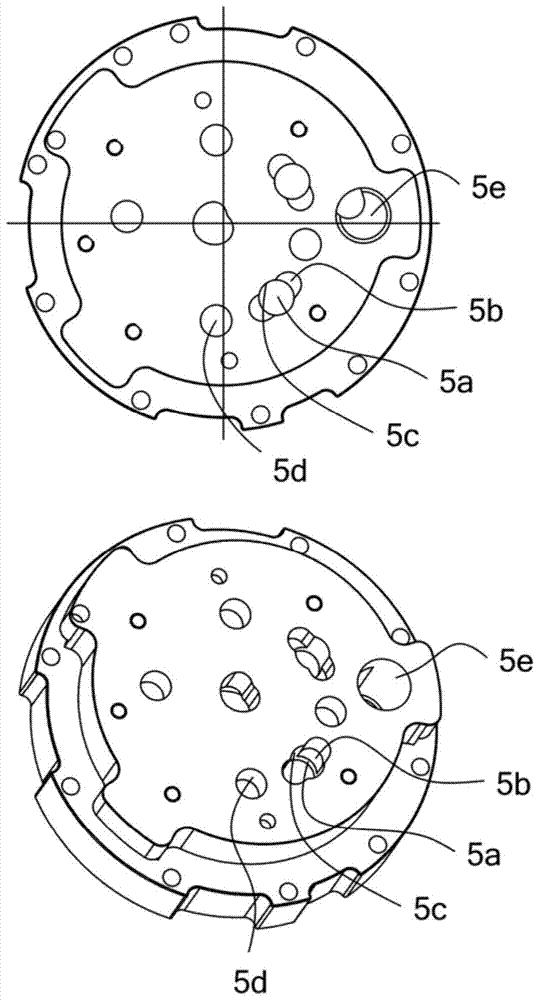

[0071] First, refer to Figure 1 to Figure 6 The scroll compressor 1 and the displacement mechanism 2 included in the scroll compressor 1 according to the first embodiment of the present invention will be described.

[0072] The scroll compressor 1 may include: a casing assembly; a compression mechanism; a drive mechanism 3 ; a support mechanism; a suction pipe 7 ;

[0073] In the illustrated example, the scroll compressor 1 is shown as a hermetic high-pressure side scroll compressor. However, it should be understood that the present invention is not limited to a hermetic high-pressure side scroll compressor, but can also be applied to, for example, a hermetic low-pressure side scroll ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com