Automatic control door

A pneumatic control system, a technology for moving doors, applied in the field of new technology applications, can solve the problems of mechanical doors not having a visual function, inconvenient opening and closing of doors, poor sealing effect, etc. The combined structure is compact and the sound insulation effect is obvious.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

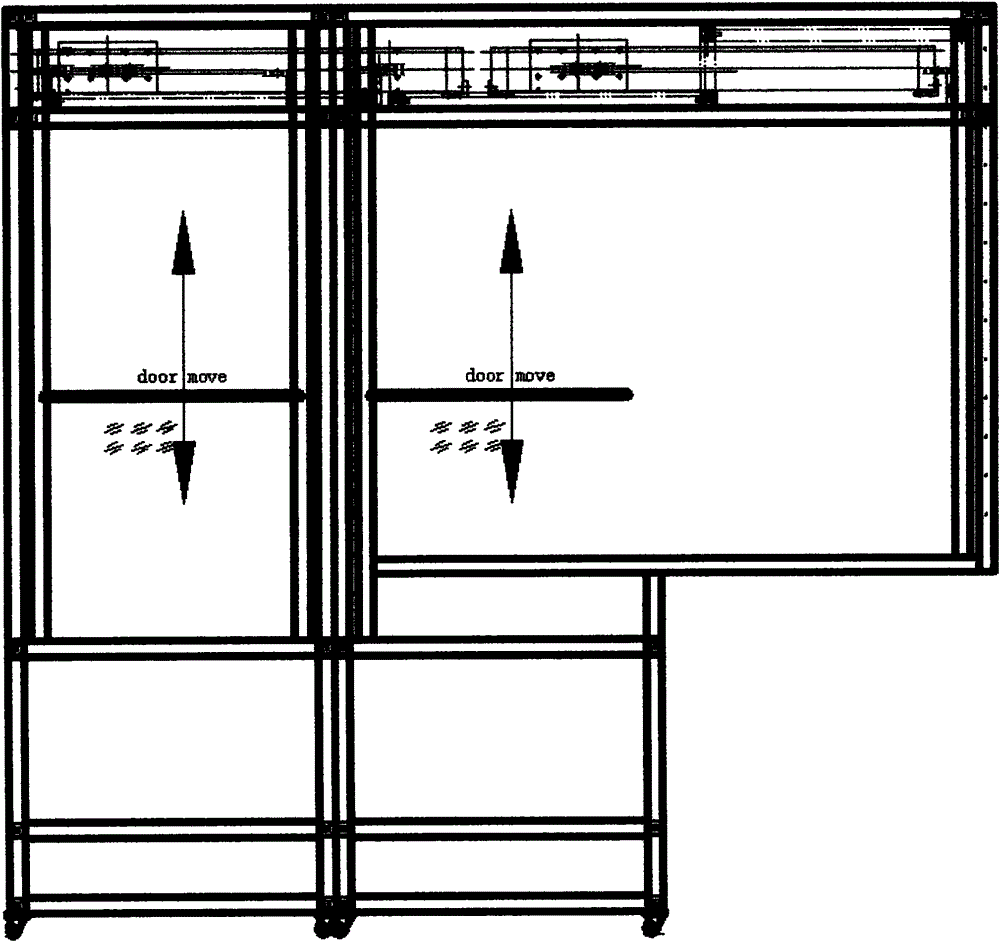

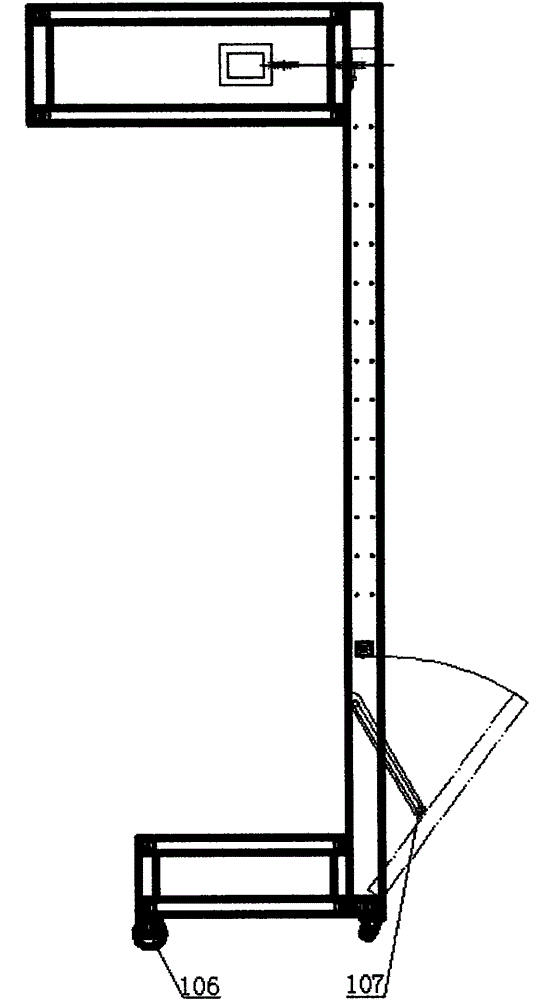

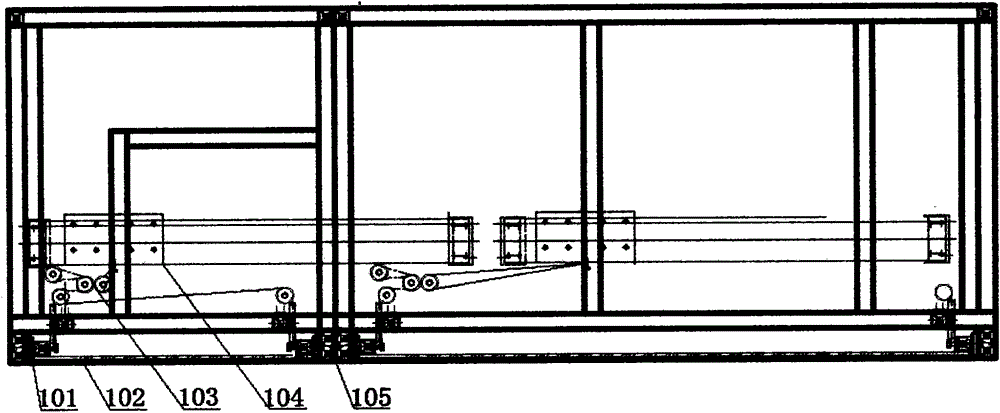

[0022] The following will be combined with Figure 6 The present invention will be described in further detail.

[0023] An automatic control door includes three parts: a lifting mechanism, an electric control structure and a lower layer.

[0024] Lifting mechanism 109 is installed in the rear of both sides of GD movable door, and its structure is as follows: Figure 6 As shown, it includes 7603 industrial super heavy-duty three-section ball guide rail 101, galvanized steel wire rope 204 for connecting function and pulley block 103 for auxiliary function. The three-section ball guide rail is installed on both sides of the GD sliding door, which is used to stabilize the GD sliding door and guide it to move up and down. The wire rope is used to connect the GD movable door and the load cell 201 of the electrical control system. The pulley group is strung on the wire rope to realize the stable lifting of the GD sliding door. During use, the GD moves the door handle up and down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com