Indoor drying component with good fixation effect

A component and fixing rod technology, which is applied in applications, household utensils, washing devices, etc., can solve the problems of affecting the quality and speed of drying, and the accumulation or blowing of drying objects, so as to achieve good fixity and protection, large drying space, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

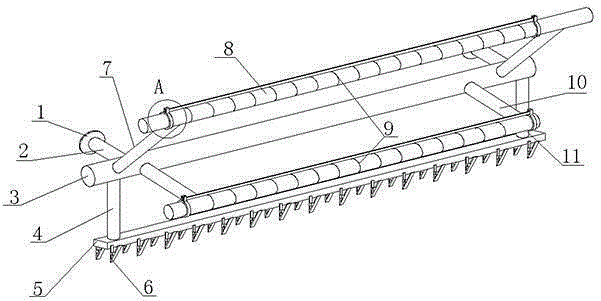

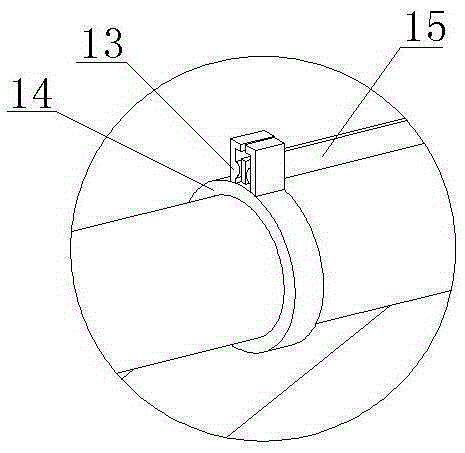

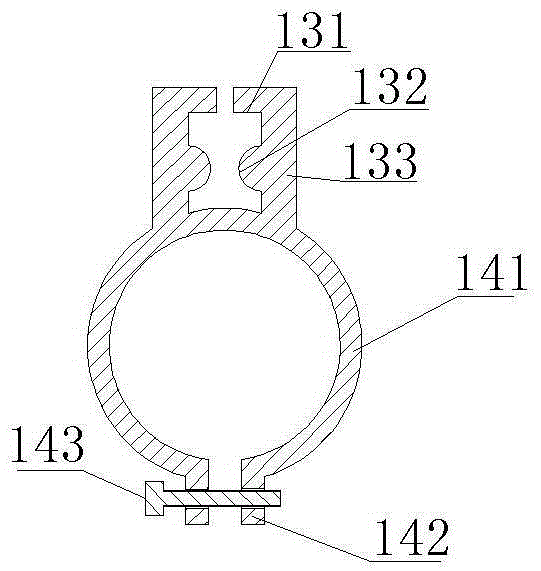

[0020] Such as Figure 1-Figure 4 The indoor drying assembly with a good fixing effect includes a fixed rod 3, the fixed rod 3 is connected to the fixed plate 1 through the horizontal connecting rod 2, and the lower end of the fixed rod 3 is also connected to the lower splint 5 through the vertical rod 4, Both sides of the lower splint 5 are provided with a plurality of clips 6 along the axial direction, and the fixed rod 3 is also provided with a horizontal support rod 10 relative to the horizontal connecting rod 2, and the horizontal support rod 10 is connected with a lower parallel drying rod 11. The fixed rod 3 is located at the upper end of the horizontal support rod 10 and is also provided with an oblique pole 7. The oblique pole 7 is connected with an upper parallel drying rod 8, and the upper parallel drying rod 8 is located at the upper end of the lower parallel drying rod 11, and the upper parallel drying rod 8 is connected to the upper end of the lower parallel dryin...

Embodiment 2

[0024] This embodiment is optimized as follows on the basis of embodiment 1: the upper end of the lower parallel drying rod 11 is also provided with the pressing device.

[0025] In this embodiment, in order to ensure that the drying objects can be fixed firmly, the above-mentioned pressing device is also provided on the upper end of the lower parallel drying object bar 11, and the drying objects at the upper end of the lower parallel drying object bar 11 can be fixed by the pressing device.

Embodiment 3

[0027] This embodiment is optimized as follows on the basis of Embodiment 1 or Embodiment 2: an included angle of a certain angle is formed between the inclined strut 7 and the horizontal strut 10, and the value range of the angle α of the included angle is 30 °≤α≤55°.

[0028] In this embodiment, the oblique strut 7 is arranged obliquely upward, forming a certain angle with the horizontal support strut 10, and the value range of the angle α of the included angle is 30°≤α≤55°, so that the upper parallel The drying bar 8 and the lower parallel drying bar 11 have enough space to dry clothes, which can improve the drying quality, and the upper parallel drying bar 8 and the lower parallel drying bar 11 are horizontally separated from each other. Both drying objects are not affected, can reach very good drying effect, can also make the drying object of upper parallel drying object bar 8 block the drying object of lower parallel drying object bar 11, play good blocking effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com