High-strength high-tenacity alloy cast steel material used for draw gears of railway vehicles

A technology for alloy cast steel and railway vehicles, which is applied in the field of alloy cast steel and can solve problems such as coupler cracks and fractures

Inactive Publication Date: 2016-01-27

CRRC YANGTZE CO LTD

View PDF5 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0008] However, with the development of heavy-duty railway transportation, the train formation is getting larger and larger, and the tensile and compressive loads on the couplers during operation are increasing. Although the use of improved materials meets the strength requirements, the couplers continue to appear. Cracks, Fractures

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

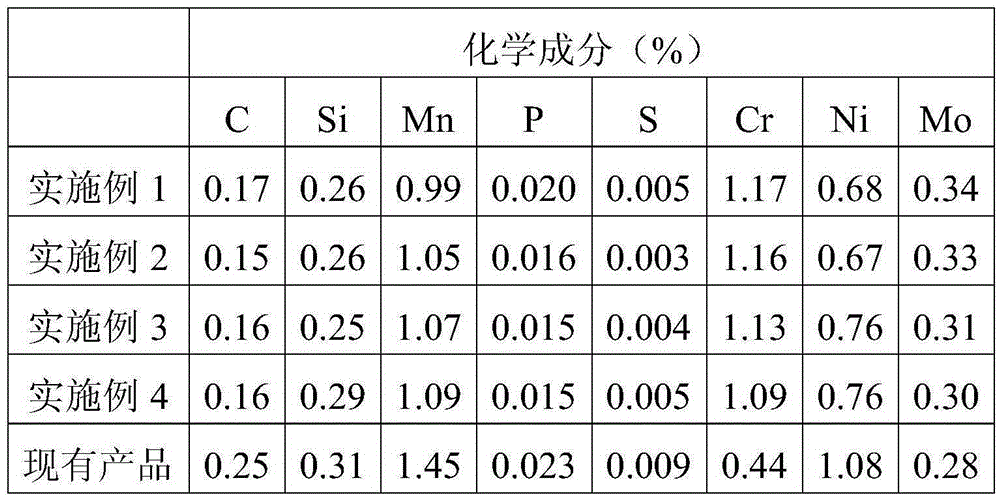

[0025] In order to better explain the present invention, the main content of the present invention is further clarified below in conjunction with specific examples, but the content of the present invention is not limited to the following examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a high-strength high-tenacity alloy cast steel material used for draw gears of railway vehicles. The alloy caste steel material is composed of, by weight, 0.14-0.20 part of C, 0.20-0.40 part of Si, 0.90-1.20 parts of Mn, 1.00-1.20 parts of Cr, 0.60-0.90 part of Ni, 0.20-0.40 parts of Mo, 0-0.030 part of S, 0-0.030 part of P and the balance Fe and inevitable impurities. According to the alloy caste steel material, the yield strength is equal to or larger than 800 MPa, the tensile strength is equal to or larger than 920 MPa, the elongation is equal to or larger than 14%, the percentage reduction of area is equal to or larger than 40%, and the ballistic work at the temperature of-40 DEG C is equal to or larger than 35 J.

Description

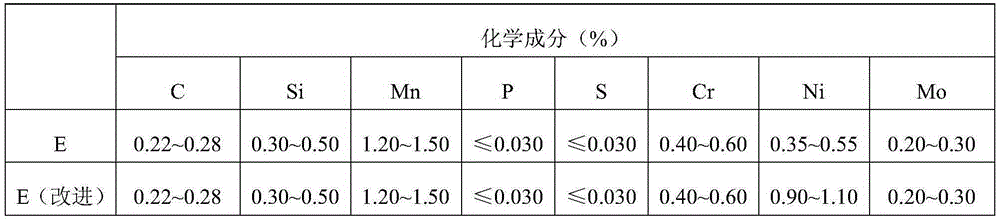

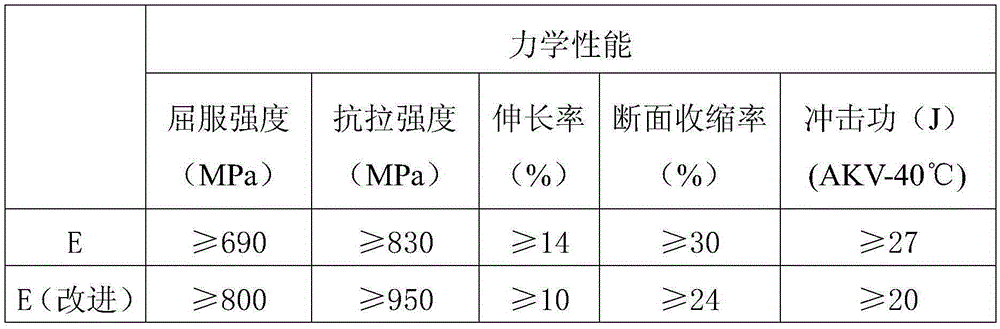

technical field [0001] The invention relates to alloy cast steel, in particular to a high-strength, high-toughness alloy cast steel material used for railway vehicle couplers (including couplers and knuckles). Background technique [0002] The coupler is the main load-bearing part of the railway vehicle. It realizes the connection between the locomotive and the vehicle or between the vehicle and the vehicle and transmits the traction and impact force. The material selection of the coupler has an important impact on its safety. At present, my country's coupler materials are mainly equivalent to the E-grade steel of the AARM-201 standard specification, and even higher-strength improved E-grade steel materials. The chemical composition requirements are shown in Table 1: [0003] Table 1 [0004] [0005] The mechanical performance requirements are as follows: [0006] Table 2 [0007] [0008] However, with the development of heavy-duty railway transportation, the trai...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C38/44

Inventor 刘涛焦辉武永亮江锐峰向尚林熊兵付祥鄢卓明苟春林王连华赖明

Owner CRRC YANGTZE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com