Super heavy oil sagd circulating preheating liquid treatment system

A technology of circulating preheating and liquid treatment, applied in the direction of multi-stage series refining process treatment, etc., can solve the problems that natural evaporation cannot meet the requirements, comprehensive treatment performance hinders SAGD and other problems, and achieves strong comprehensive performance, reduced energy consumption, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

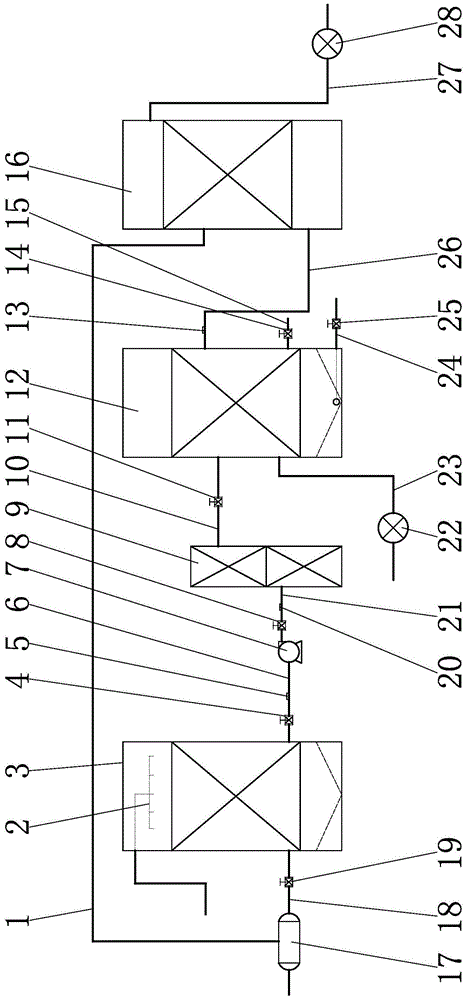

[0010] A super-heavy oil SAGD circulation preheating liquid treatment system, such as figure 1 Shown, comprise vapor-liquid separator 17, spray type cooling device, tubular reactor 9, sludge water three-phase separator 12 and steam heating type crude oil gravity settler 16, spray type cooling device comprises cooling tank 3, in When the spray cooler itself is working, it is located inside the cooling tank 3, facing the gravitational direction, and the sprayer 2 and the corrugated plate heat exchange device that can be sprayed downward are installed in turn, and the sludge water three-phase separator 12 includes a degreasing settling tank 1. When the oil-sludge-water three-phase separator 12 is working by itself, it is located inside the oil removal settling tank and is sequentially installed with an oil collection device, a water collection and distribution device, and a sludge discharge device in the direction of gravity; it also includes a steam delivery pipeline 1 and a firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com