Catalyst for polyester preparation and its preparation method and application

A catalyst, polyester technology, applied in the preparation of this catalyst, polytrimethylene terephthalate, the field of polyester manufacturing, can solve problems such as no reported polyester

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

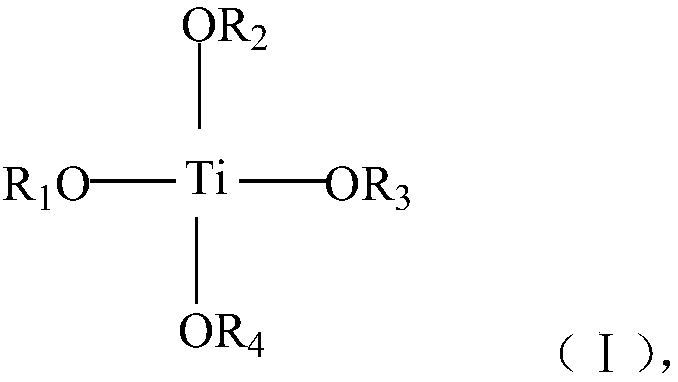

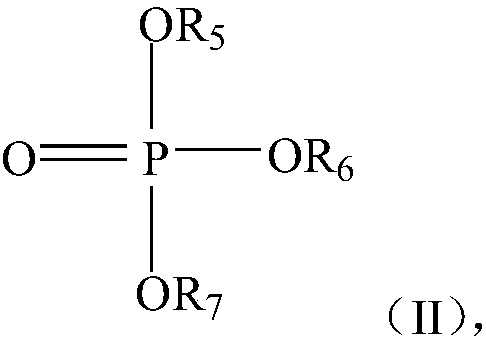

Method used

Image

Examples

Embodiment 1

[0055] Mix 142g of tetraisopropyl titanate with 46g of ethanol and 90g of lactic acid, and react for 4 hours at a temperature of 100°C in a stirred reactor. Add 36g of magnesium acetate and 91g of triethyl phosphate to the reactant. In the reactor, the reaction was carried out for 4 hours under the temperature condition of 120°C. The reaction product is placed in a reactor equipped with a fractionation device, and ethanol and isopropanol are distilled off to make a catalyst. The catalyst is mixed with 1,3-propanediol, wherein the mass fraction of titanium atoms is 4%.

[0056] 600 grams of terephthalic acid, 440 grams of 1,3 propylene glycol and 1.49 g of catalyst were mixed to form a slurry, which was added to a polymerization kettle for esterification reaction. The esterification temperature was 230 °C and the pressure was 0.25 MPa. The device discharges the water generated by the reaction, reacts for 2 hours, and the esterification rate is 96%. After the esterification is...

Embodiment 2

[0059] Mix 142g of tetraisopropyl titanate with 46g of ethanol and 192g of citric acid, and react for 4 hours at 100°C in a stirred reactor, add 36g of magnesium acetate and 91g of triethyl phosphate to the reactant, and In a stirred reactor, the reaction was carried out at a temperature of 120° C. for 4 hours. The reaction product is placed in a reactor equipped with a fractionation device, and ethanol and isopropanol are distilled off to make a catalyst. The catalyst is mixed with 1,3-propanediol, wherein the mass fraction of titanium atoms is 4%.

[0060] 600 grams of terephthalic acid, 440 grams of 1,3 propylene glycol and 1.49 g of catalyst were mixed to form a slurry, which was added to a polymerization kettle for esterification reaction. The esterification temperature was 230 °C and the pressure was 0.25 MPa. The device discharges the water generated by the reaction, and reacts for 2 hours, and the esterification rate is 97%. After the esterification is completed, the...

Embodiment 3

[0063] Mix 142g of tetraisopropyl titanate with 46g of ethanol and 192g of citric acid, and react for 4 hours at a temperature of 100°C in a stirred reactor, and add 61g of zinc lactate and 91g of triethyl phosphate to the reactant. In a stirred reactor, the reaction was carried out at a temperature of 120° C. for 4 hours. The reaction product is placed in a reactor equipped with a fractionation device, and ethanol and isopropanol are distilled off to make a catalyst. The catalyst is mixed with 1,3-propanediol, wherein the mass fraction of titanium atoms is 4%.

[0064] 600 grams of terephthalic acid, 440 grams of 1,3 propylene glycol and 1.49 g of catalyst were mixed to form a slurry, which was added to a polymerization kettle for esterification reaction. The esterification temperature was 230 °C and the pressure was 0.25 MPa. The device discharges the water generated by the reaction, reacts for 2 hours, and the esterification rate is 96%. After the esterification is complete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com