Spherical potassium perchlorate production technology

A technology of potassium perchlorate and production process, applied in the directions of perchloric acid, perchlorate, etc., can solve the problems of poor product spheroidization, difficult to produce, and high price, achieve high spheroidization degree, reduce a lot of cost, and large output Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

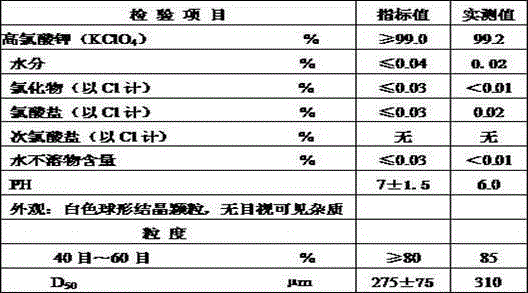

[0014] With 5 tons of potassium perchlorate as the raw material for this implementation, the raw material indicators used are as follows:

[0015]

[0016] 1) Feed 500 kg of potassium perchlorate corresponding to 3000 kg of tap water for refining as the refined liquid. Due to the problem of the plant equipment line, it is decided to stop temporarily, and this solution is used as the saturated liquid;

[0017] 2) After all the equipment and lines of the whole plant have been adjusted, use 250 kg of potassium perchlorate corresponding to step 1) of 3 cubic meters of saturated liquid to refine the material, open the heating valve to completely dissolve the solid, and measure the solution when the temperature reaches 100°C The specific gravity is 1.050-1.065, continue to heat for 20 minutes, close the heating valve, settle for 30 minutes, send the refined solution to the settling tank by the submerged pump, and stand still for 30 minutes to obtain the refined solution;

[0018]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com