Transportation tool for finished pipelines with flanges

A technology for flanges and pipes, which is applied in the field of finished pipes, can solve the problems of limited pipe wall pressure, poor stability of stacking methods, and paint damage at contact points, etc., to achieve less fixing measures, ingenious design, and anti-overturning powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

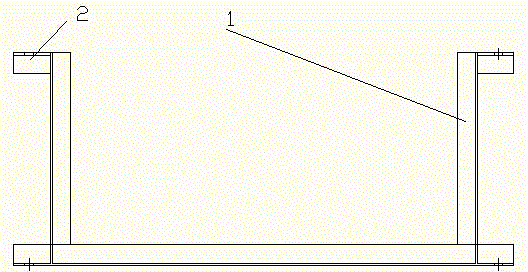

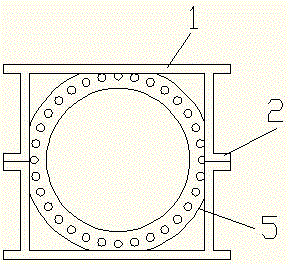

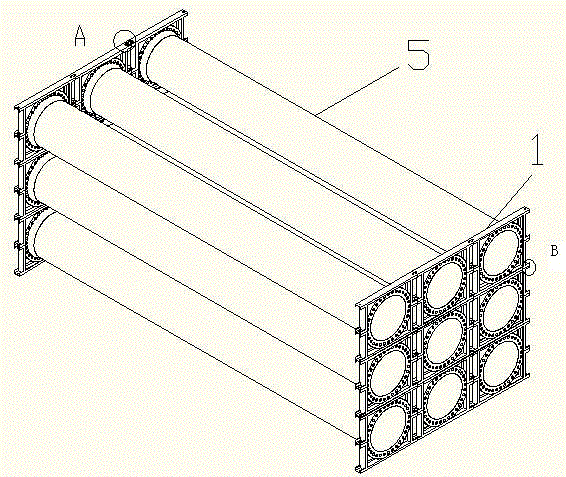

[0015] Such as figure 1 , image 3 As shown, a transport tooling with flanged finished pipelines, which includes mxn units, where m and n are both greater than or equal to 2, figure 1 The average value of the center is 3, each unit is a box, and the box is formed by splicing two flange brackets 1; the size of the box matches the flange of the pipeline to be transported, and the two flange brackets are spliced There is a connecting edge 2 at the center and is fixedly connected by bolts 3 and nuts 4, and the flanges 5 at both ends of each finished pipe with flanges are respectively clamped in the unit.

[0016] figure 2 Among them, the two sides of the upper and lower flange brackets of the unit protrude outward respectively, and the upper and lower flange brackets directly use bolts to connect the upper and lower units through the extension section.

[0017] Figure 4 Among them, the units of the transport tooling are overlapped by connecting plates 6 in the transverse dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com