Automatic FFC pressure connecting forming machine

A molding machine and automatic technology, which is applied in metal processing and other directions, can solve the problems of poor sticking position of reinforcing plate, inaccurate punching position, and poor margin cutting, etc., achieves high degree of automation, improves yield rate, and is easy to batch The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

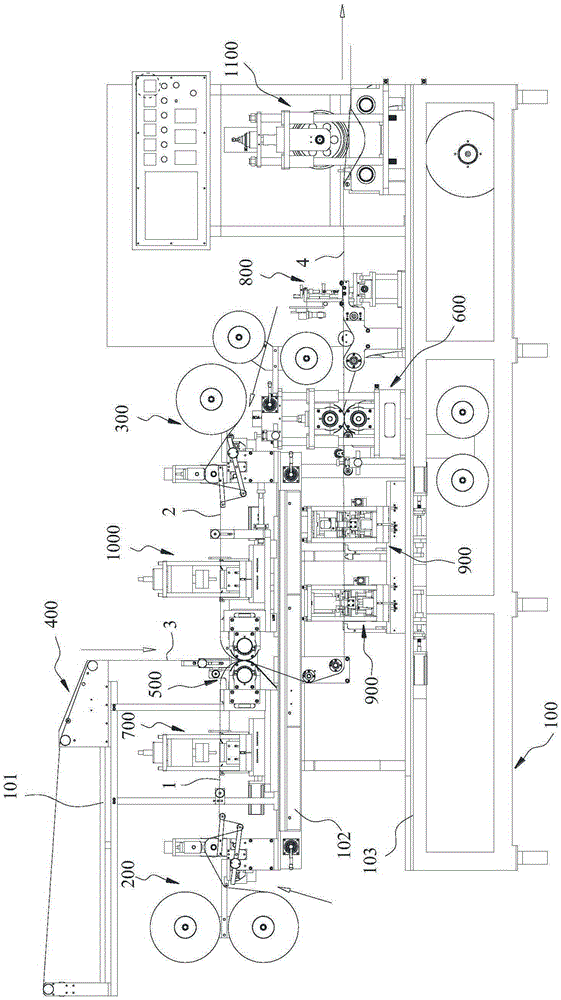

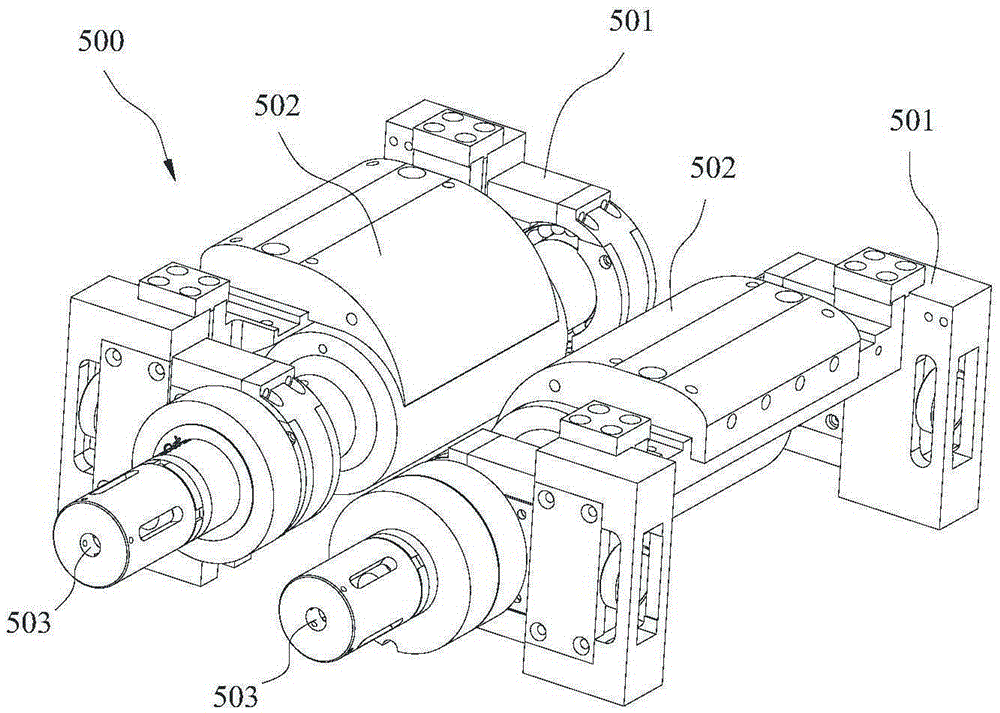

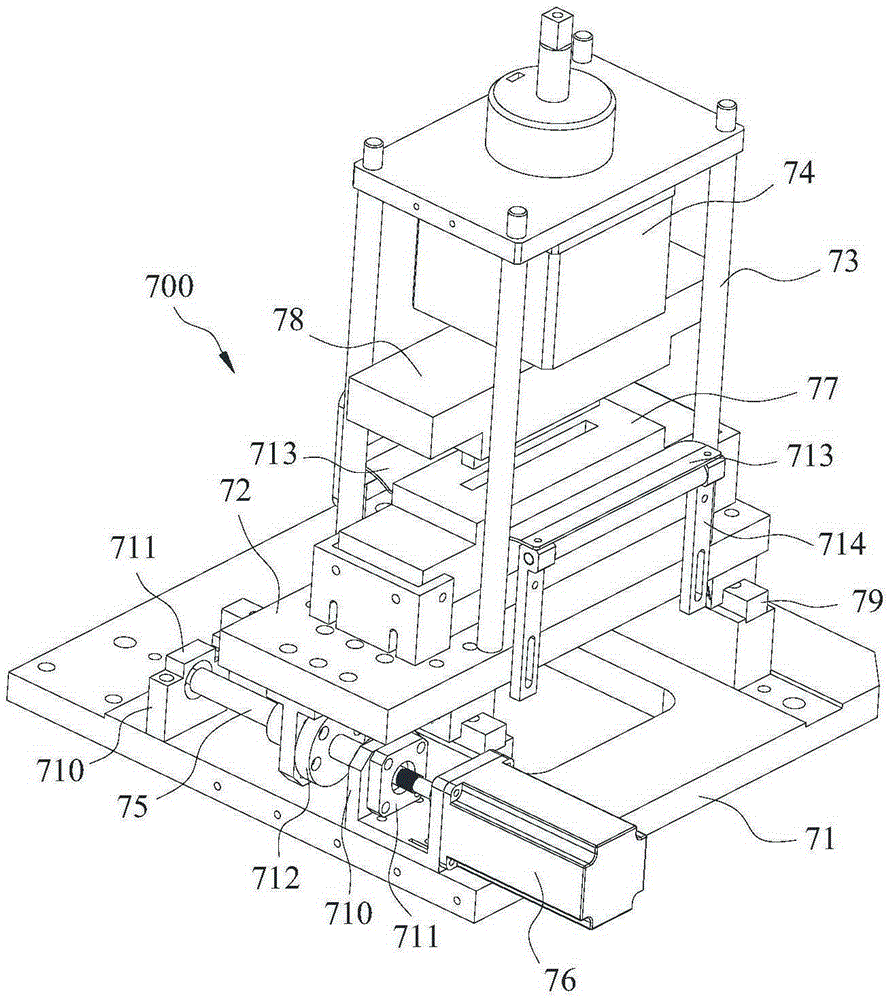

[0032] Such as figure 1The automatic FFC crimping forming machine shown includes a frame 100, a first film feeding mechanism 200 for conveying the upper film 1, a second film conveying mechanism 300 for conveying the lower film 2, and a metal conductor 3 for conveying. Conductor feeding mechanism 400, first hot-pressing device 500, second hot-pressing device 600, first punching device 700, second punching device 1000, patching and reinforcing plate device 900 and slitting device 800, frame 100 is divided into top layer Frame 101, middle frame 102 and bottom frame 103, conductor feeding mechanism 400 is installed on top frame 101, the first film feeding mechanism 200 and the second film feeding mechanism 300 are respectively located at the two ends of middle frame 102, the first heat press device 500 is installed In the middle shelf 102 and between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com