Adaptive egg quick pick-and-place device

A pick-and-place device and self-adaptive technology, applied in the direction of manipulators, program-controlled manipulators, chucks, etc., can solve the problems of pick-and-place, inability to completely absorb poultry egg arrays, and poultry egg arrays that cannot be at any angle, to achieve flexible position movement, The effect of reducing inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

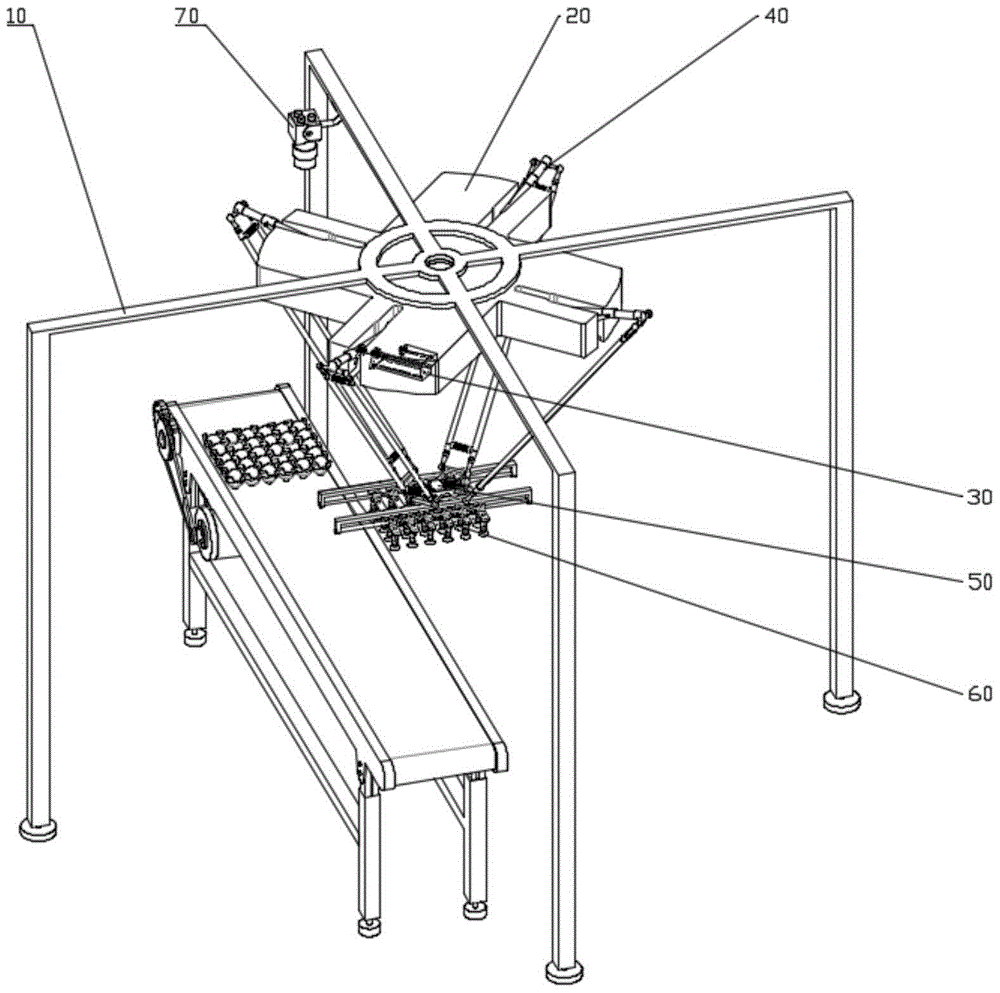

[0033] Such as figure 1 Shown, the present invention comprises frame 10, conveyer belt, the fixed platform 20 that is fixed on the frame 10, the four groups of motor assemblies 30 that center is symmetrically fixed on the four directions on fixed platform 20, respectively with four groups of motor assemblies 30 Four sets of connected control arms 40, a moving platform 50 located below the fixed platform 20 and connected and controlled by the four sets of control arms 40, an end pick-and-place mechanism 60 fixed under the moving platform 50, and a machine vision component 70 installed above the conveyor belt.

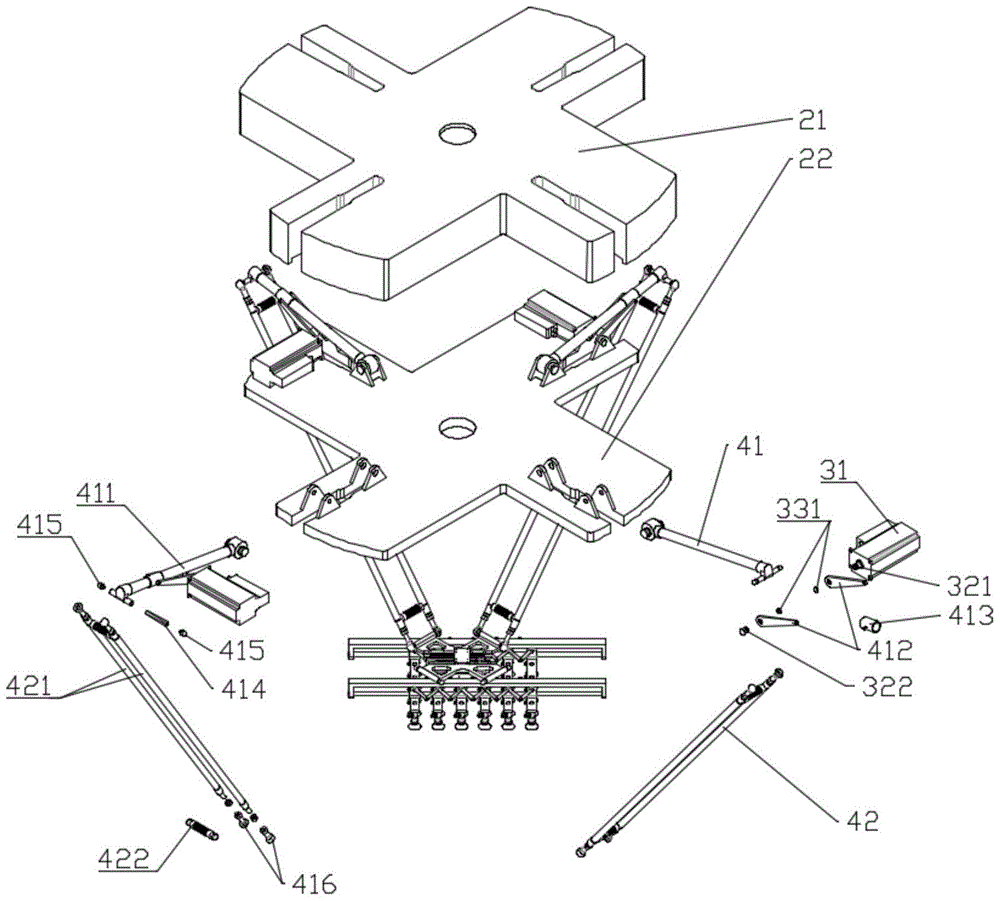

[0034] Such as figure 2As shown, the fixed platform 20 includes a fixed platform cover 21 and a fixed platform plate 22 installed up and down, and a part of four motor assemblies 30 and the control arm assembly 40 connected re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com