A kind of equipment for manufacturing cast magnesium structural parts of large spacecraft

A technology for spacecraft and structural parts, applied in casting and forming equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of difficult production and large area, and achieve the effect of simple sand box and small area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The equipment for manufacturing large-scale spacecraft cast magnesium structural parts according to the invention comprises a sand box unit, a sand core unit and a casting unit.

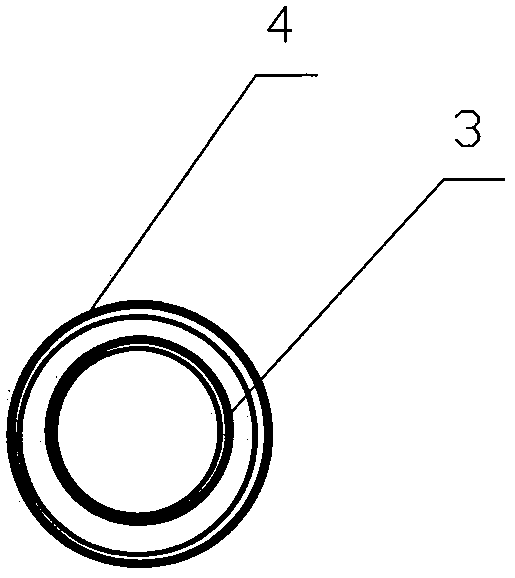

[0049] The flask unit includes a flat flask 1 at the bottom, an outer flask 2 , a first inner flask 3 and a second inner flask 4 .

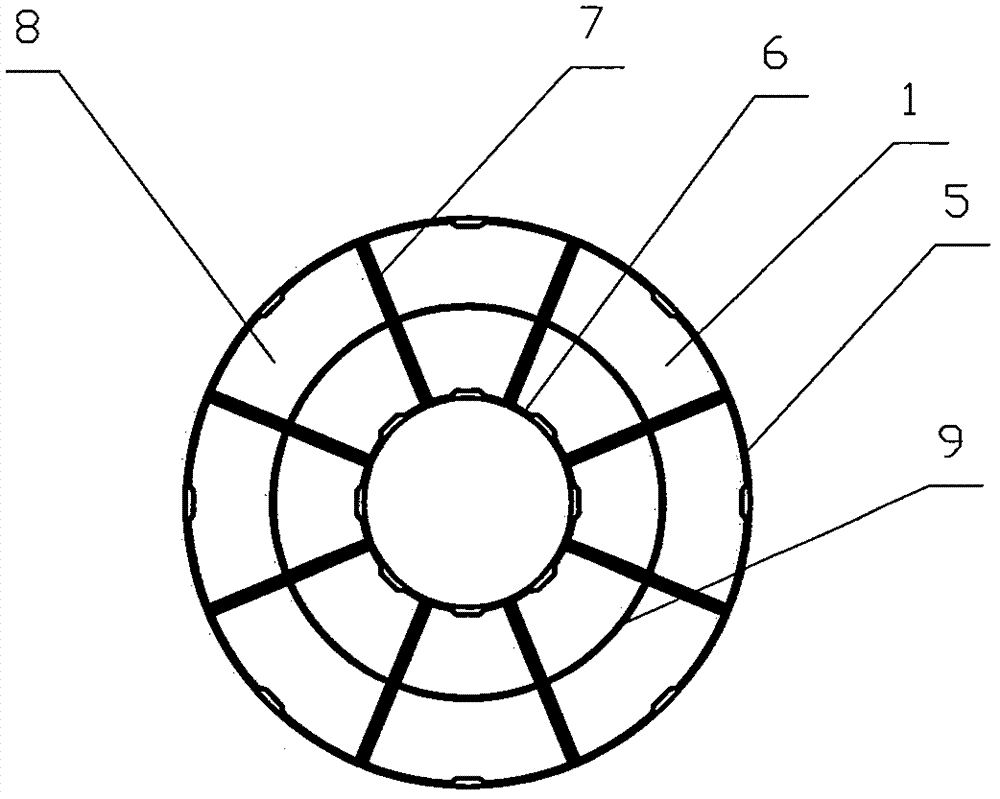

[0050] Flat sand box 1, see figure 1 As shown, there is a circular flask support, the support includes a ring-shaped nested first ring 5, and a second ring 6 concentric with the first ring 5 and located inside the first ring 5; Between the circular ring 5 and the second circular ring 6, there are a plurality of evenly distributed radial connectors 7 for connecting the two circular rings; as a preferred embodiment, the preferred planar flask 1 consists of several equally Planar sand box 8 is formed, most preferably is made up of 8 equally divided plane sand boxes 8;

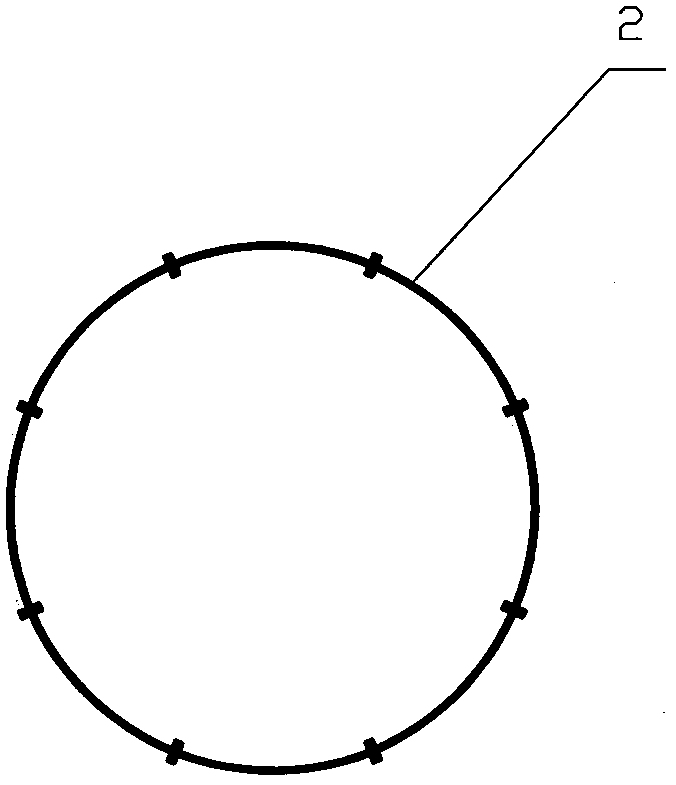

[0051] Outer sand box 2, see figure 2 As shown, it is an annular support, and the inner diame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com