UV curing machine provided with 360-degree rotary light source

A technology of rotating light source and curing machine, which is applied to the device for coating liquid on the surface, pretreatment surface, coating, etc. It can solve the problems of poor ink adhesion, affect product quality, low light temperature, etc., and improve production. Efficiency and product quality, ensuring irradiation range and stability, enhancing the effect of irradiation energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

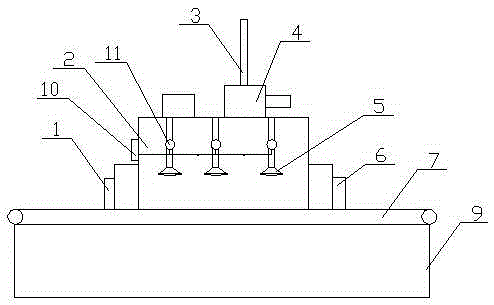

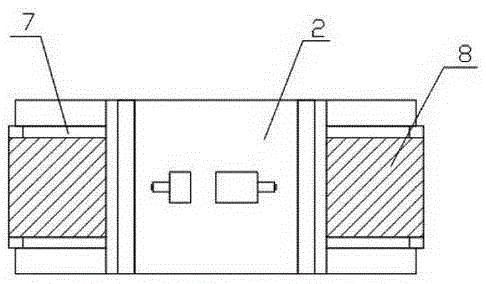

[0016] In this example, if figure 1 , figure 2 As shown, the present invention includes a UV curing machine body, and the UV curing machine body is provided with a feed port, a discharge port, an exhaust fan and a transmission table, wherein the feed port and the discharge port are respectively located on both sides of the UV curing machine body , There is a UV lamp inside the UV curing machine body, the exhaust fan is installed on the top of the UV curing machine body, a conveyor belt is installed on the upper end of the transmission table, and light-absorbing paper is laid on the conveyor belt;

[0017] At the same time, it also includes an electric control device, the electric control device is installed above the feed port of the UV curing machine body, and the UV lamp is rotatably installed inside the UV curing machine body through a rotating bearing, wherein the The above-mentioned rotary bearing is connected with electric wires of the electric control device, and its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com